MCAC-TSM-2008-02 Hydraulic Connection

Installation 69

close to plate heat exchanger. Provided the pump installed outside of unit, the pump shall be connected at

water pipe’s outlet. The pump can be easily installed on the unit by removing the pump connection pipe.

Important

1) The chillers must be provided with a filling/top-up system connected to the return line and a drain cock

in the lowest part of the installation. Installations containing anti-freeze or covered by specific legislation

must be fitted with hydraulic disconnections.

2) The manufacturer is not liable for obstruction, breakage or noise resulting from the failure to install filters

or vibration dampers. Particular types of water used for filling or topping up must be treated with

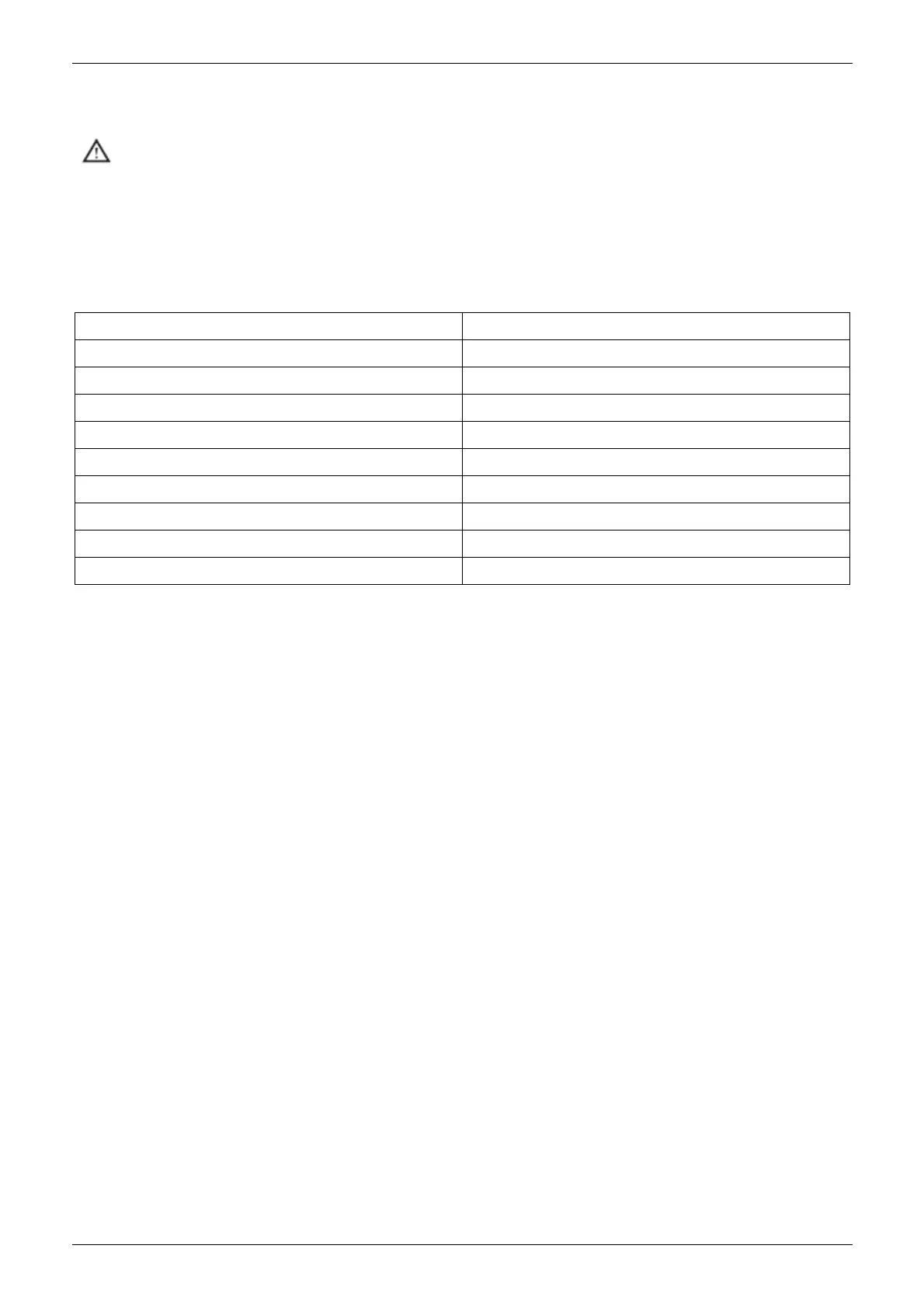

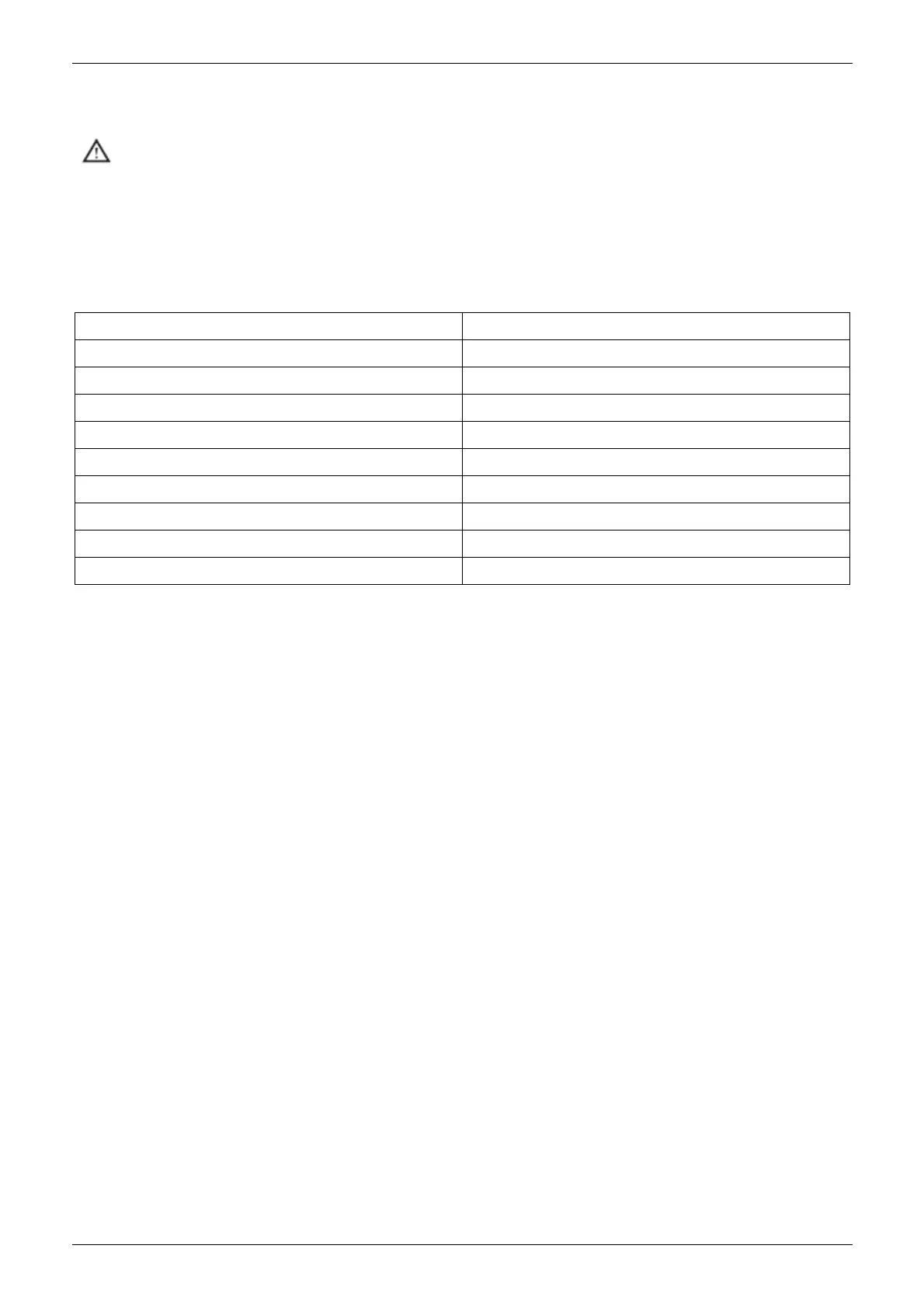

appropriate treatment systems. For reference values, see the table.

PH 6-8

Electrical conductivity

less than 200 mV/cm (25°C)

Chlorine ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

Total iron less than 50 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions none

Ammonia ions none

Silicon ions less than 30 ppm

Filling the installation

- Before filling, check that the installation drain cock is closed.

- Open all installation and terminal air vents.

- Open the gate valves.

- Begin filling, slowly opening the water filling cock outside the unit

- When water begins to leak out of the terminal air vent valves, close them and continue filling until the

pressure gauge indicates a pressure of 1.5 bars.

Emptying the installation

- Before emptying, place the mains switch in the“off” position

- Make sure the installation fill/top-up water cock is closed

- Open the drain cock outside the unit and all the installation and terminal air vent valves.

Loading...

Loading...