V8 Mini R410A VRF 50Hz

83

Part 3 - System Design and Installation

3 Refrigerant Piping Design

3.1 Design Considerations

Refrigerant piping design should take account of the following considerations:

The amount of brazing required should be kept to a minimum.

On the two inside sides of the first indoor branch joint (“A” in Figures 3-3.1 and Figure 3-3.3) the system should, as far

as possible, be equal in terms of number of units, total capacities and total piping lengths.

3.2 Material Specification

Only seamless phosphorus-deoxidized copper piping that complies with all applicable legislation should be used. Temper

grades and minimum thicknesses for different diameters of piping are specified in Table 3-3.1.

Table 3-3.1: Piping temper and thickness

Piping outer

diameter

(mm)

Notes:

1. O: coiled piping;

2. 1/2H: straight piping.

3.3 Permitted Piping Lengths and Level Differences

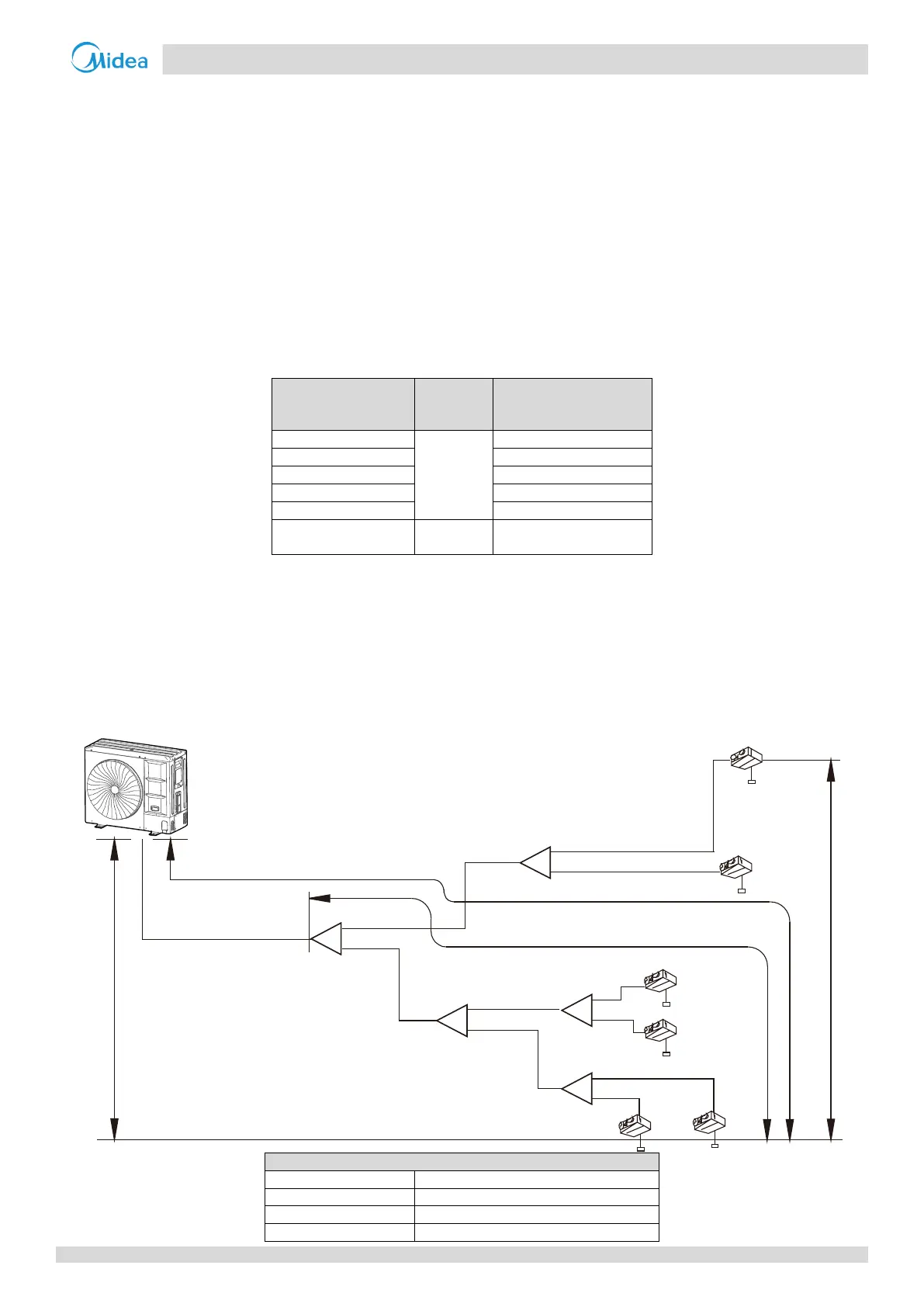

The piping length and level difference requirements that apply are summarized in Table 3-3.2 and are fully described as

follows (refer to Figure 3-3.1 and Figure 3-3.2):

Figure 3-3.1: Permitted refrigerant piping lengths and level differences

Outdoor Unit

a

N1

3N

5N

6

N

2

N

4N

b

c

e

f

d

1L

2L

5L

3

L

4

L

A

B

C

D

E

Maximum level difference between the

outdoor unit and indoor unit is ≤ 50 m

Maximum level difference between Indoor

units is ≤ 15 m

Maximum piping length from the first branch joint

to the farthest indoor unit is ≤ 40 m

Maximum equivalent piping length from the outdoor

unit to the farthest indoor unit is ≤ 120 m

First branch

joint

Loading...

Loading...