V8 Mini R410A VRF 50Hz

89

Part 3 - System Design and Installation

4 Refrigerant Piping Installation

4.1 Procedure and Principles

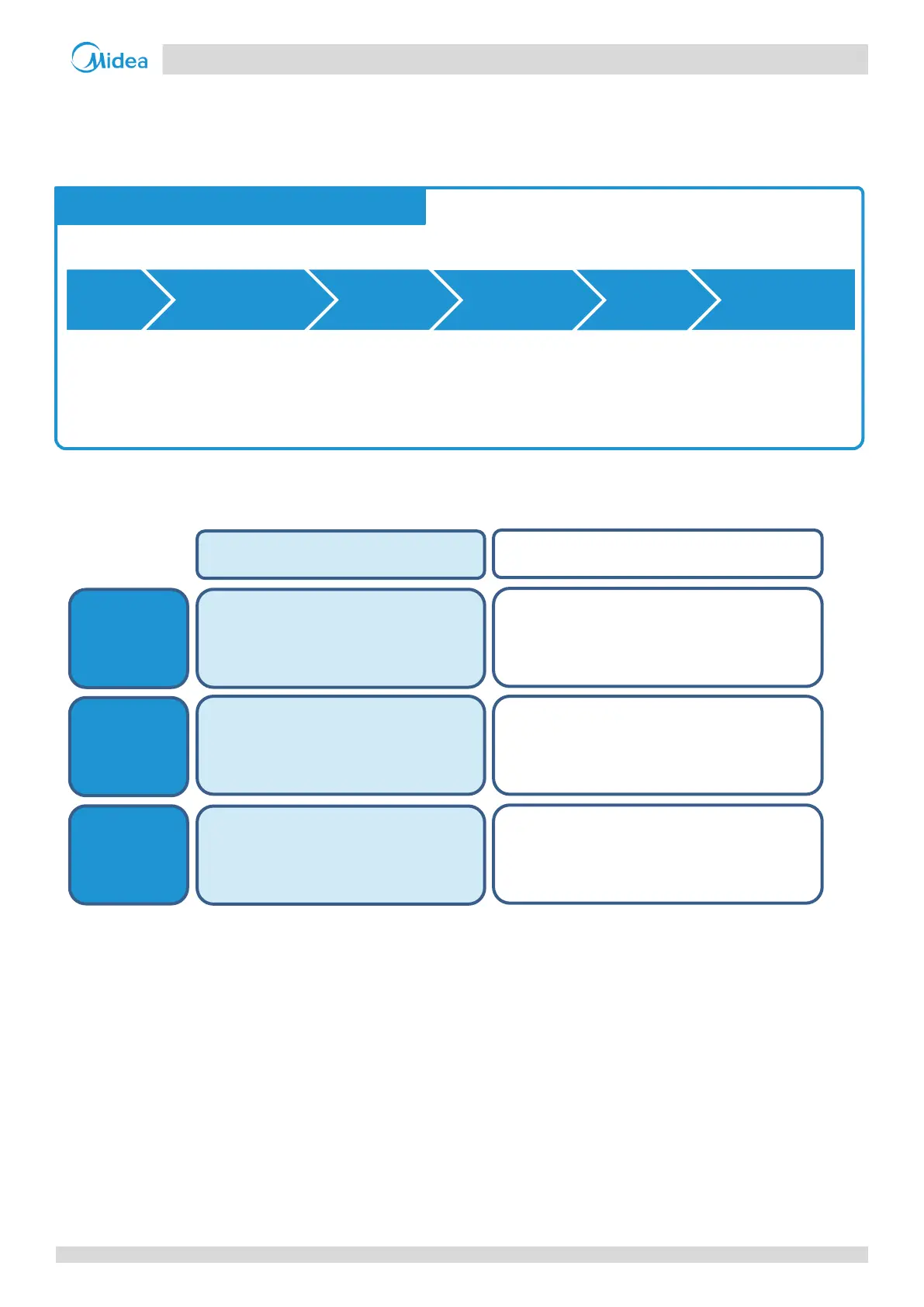

4.1.1 Installation procedure

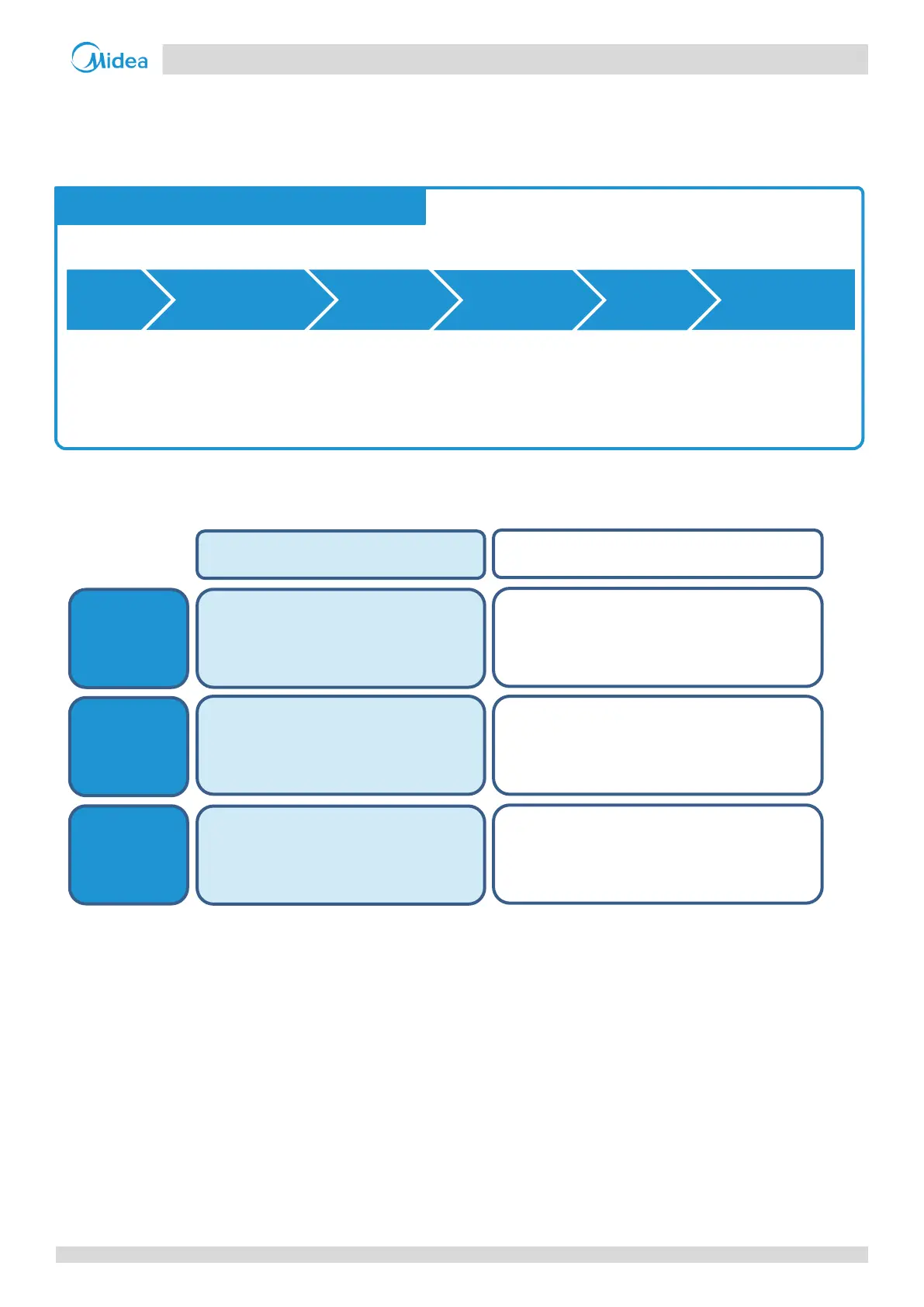

4.1.2 Three principles for refrigerant piping

Notes:

1. See Part 3, 4.2.1 “Pipe delivery, storage and sealing”.

2. See Part 3, 4.5 “Brazing”.

3. See Part 3, 4.8 “Pipe Flushing”.

4. See Part 3, 4.10 “Vacuum Drying”.

5. See Part 3, 4.3 “Manipulating Copper Piping”.

6. See Part 3, 4.9 “Gastightness Test”.

Installation of the refrigerant piping system should proceed in the following order:

Note: Pipe flushing should be performed once the brazed connections have been completed with the exception of the

final connections to the indoor units. That is, flushing should be performed once the outdoor units have been

connected but before the indoor units are connected.

Pipe brazing

and installation

Particles such as oxide produced

during brazing and/or building dust

can lead to compressor malfunction

Moisture can lead to ice formation or

oxidization of internal components

leading to abnormal operation or

compressor damage

Seal piping during storage

1

Flow nitrogen during brazing

2

Pipe flushing

3

Pipe flushing

3

Vacuum drying

4

Imperfect seals can lead to refrigerant

leakage

Pipe manipulation

5

and brazing

2

techniques

Gastightness test

6

Loading...

Loading...