V8 Mini R410A VRF 50Hz

91

Part 3

-

System Design and Installation

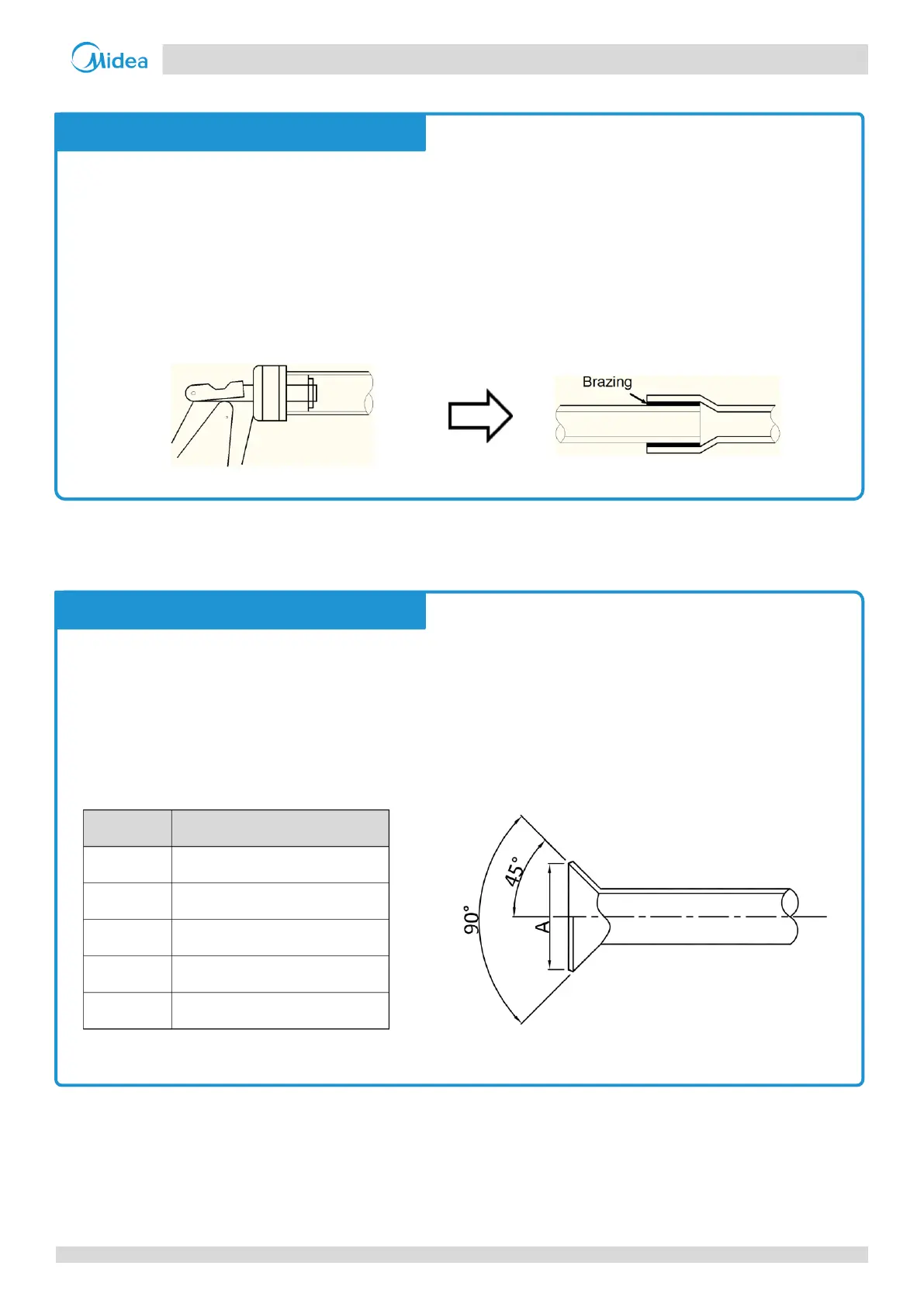

4.3.3 Expanding copper piping ends

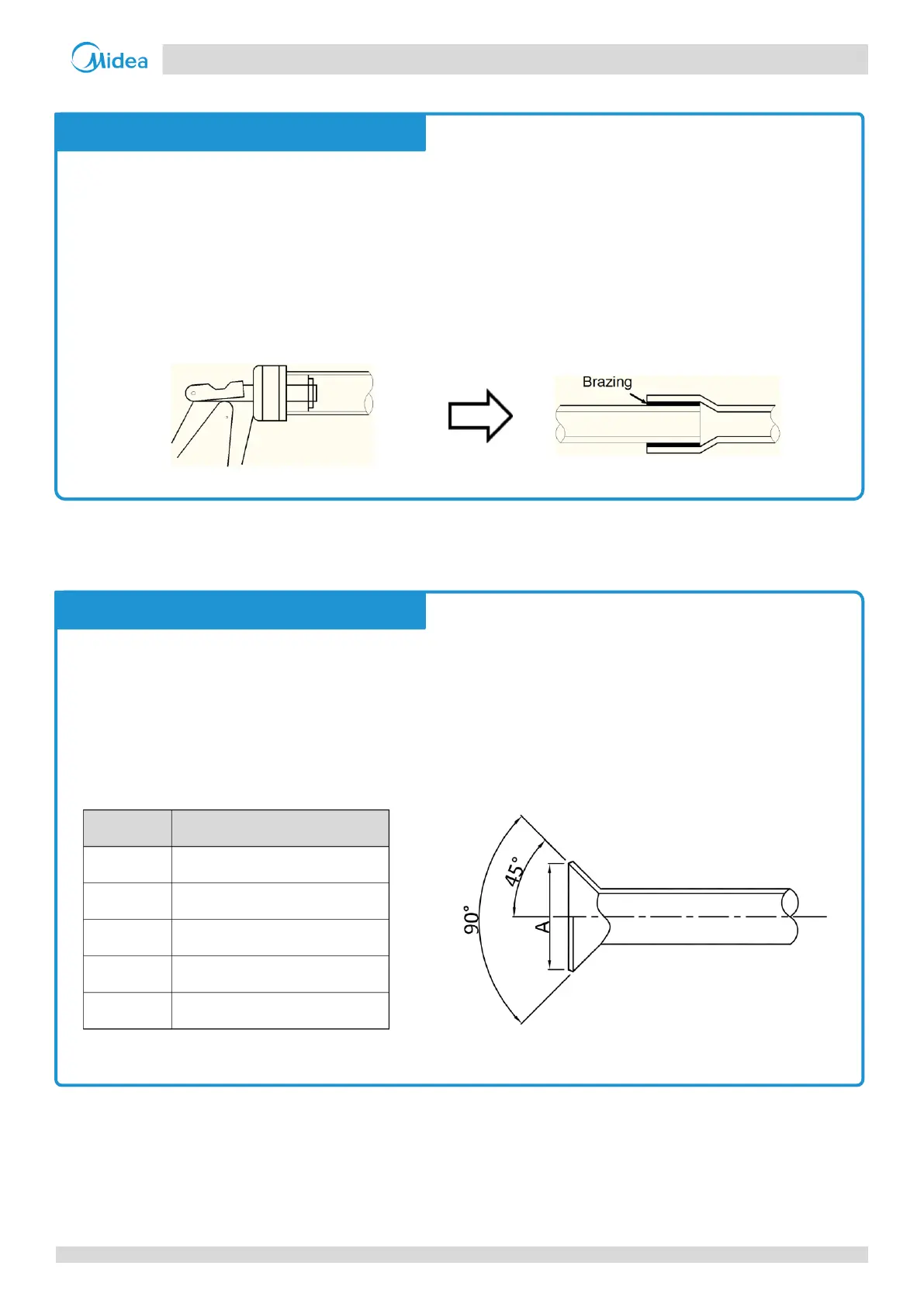

4.3.4 Flared joints

Flared joints should be used where a screw thread connection is required.

Ends of copper piping can be expanded so that another length of piping can be inserted and the joint brazed.

Insert the expanding head of the pipe expander into the pipe. After completing pipe expansion, rotate the copper

pipe a few degrees to rectify the straight line mark left by the expanding head.

Caution

Ensure that the expanded section of piping is smooth and even. Remove any burrs that remain after cutting.

Figure 3-4.1: Expanding copper piping ends

Before flaring 1/2H (half hard) piping, anneal the end of the pipe to be flared.

Remember to place the flare nut on the piping before flaring.

Ensure the flared opening is not cracked, deformed or scratched, otherwise it will not form a good seal and

refrigerant leakage may occur.

The diameter of the flared opening should be within the ranges specified in Table 3-4.1. Refer to Figure 3-4.2.

Table 3-4.1: Flared opening size ranges

Figure 3-4.2: Flared opening

Flared opening diameter (A) (mm)

When connecting a flared joint, apply some compressor oil to the inner and outer surfaces of the flared opening

to facilitate the connection and rotation of the flare nut, ensure firm connection between the sealing surface and

Loading...

Loading...