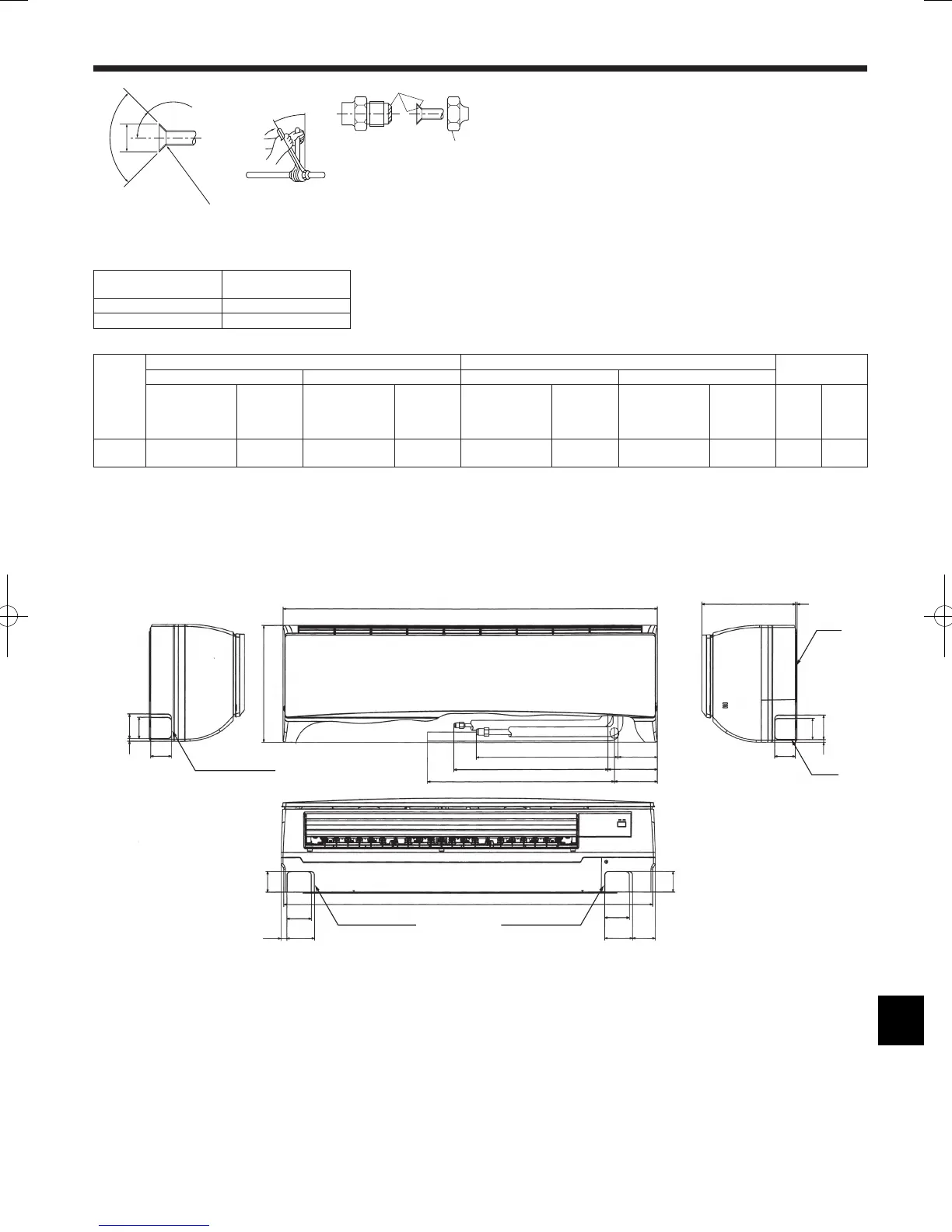

Fig. 4-1

4.1. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F

or more, thickness of 12 mm, 1/2 inch or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam

insulation materials (specific gravity of 0.03, thickness of 9 mm, 23/64 inch or

more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before

tightening flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections.

Insulate carefully.

A Flare cutting dimensions

Copper pipe O.D.

(mm, inch)

Flare dimensions

øA dimensions (mm, inch)

ø9.52, 3/8” 12.8 - 13.2, 1/2 - 33/64

ø15.88, 5/8” 19.3 - 19.7, 49/64 - 25/32

B Refrigerant pipe sizes & Flare nut tightening torque

R22 R410A

Flare nut O.D.

Liquid pipe Gas pipe Liquid pipe Gas pipe

Pipe size O.D.

(mm, inch)

Tightening

torque.

(N·m, ft·lbs)

Pipe size O.D.

(mm, inch)

Tightening

torque.

(N·m, ft·lbs)

Pipe size O.D.

(mm, inch)

Tightening

torque.

(N·m, ft·lbs)

Pipe size O.D.

(mm, inch)

Tightening

torque.

(N·m, ft·lbs)

Liquid

pipe

(mm,

inch)

Gas

pipe

(mm,

inch)

P24

P30

ODø9.52

3/8”

34 - 42

25 - 30

ODø15.88

5/8”

68 - 82

49 - 59

ODø9.52

3/8”

34 - 42

25 - 30

ODø15.88

5/8”

68 - 82

49 - 59

22

7/8

29

1-9/64

C Do not apply refrigerating machine oil to the screw portions.

(This will make the flare nuts more apt to loosen.)

DBe certain to use the flare nuts that are attached to the main unit.

(Use of commercially-available products may result in cracking.)

E Apply refrigerating machine oil over the entire flare seat surface.

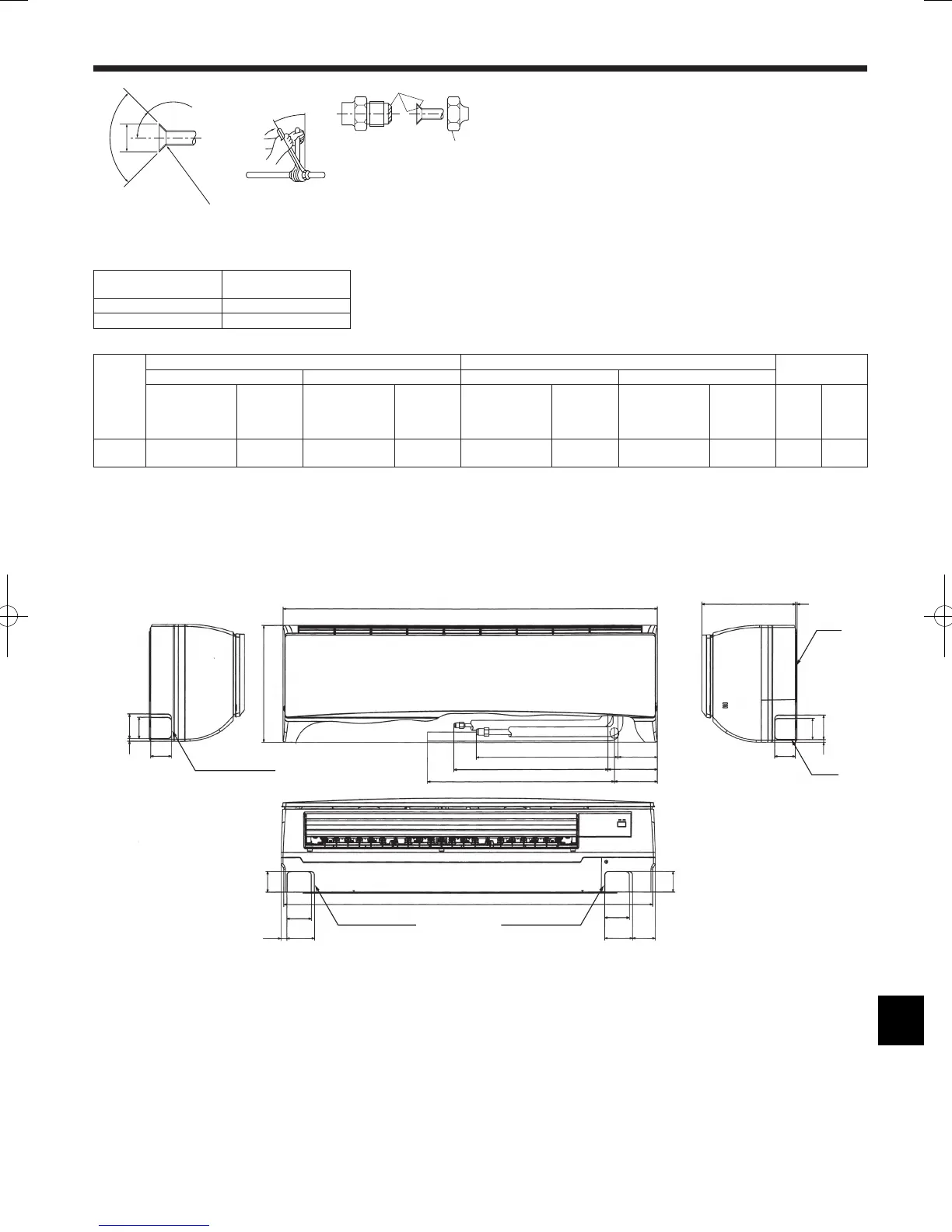

Fig. 4-2

PKFY-P·NKMU-E

4.2. Positioning refrigerant and drain piping (Fig. 4-2)

PKFY-P·NKMU-E

AGas pipe * Indicates the condition with accessories mounted.

BLiquid pipe

CDrain hose

DLeft-side piping knockout hole

ERight-side piping knockout hole

FLower piping knockout hole

G Mount board 1

Loading...

Loading...