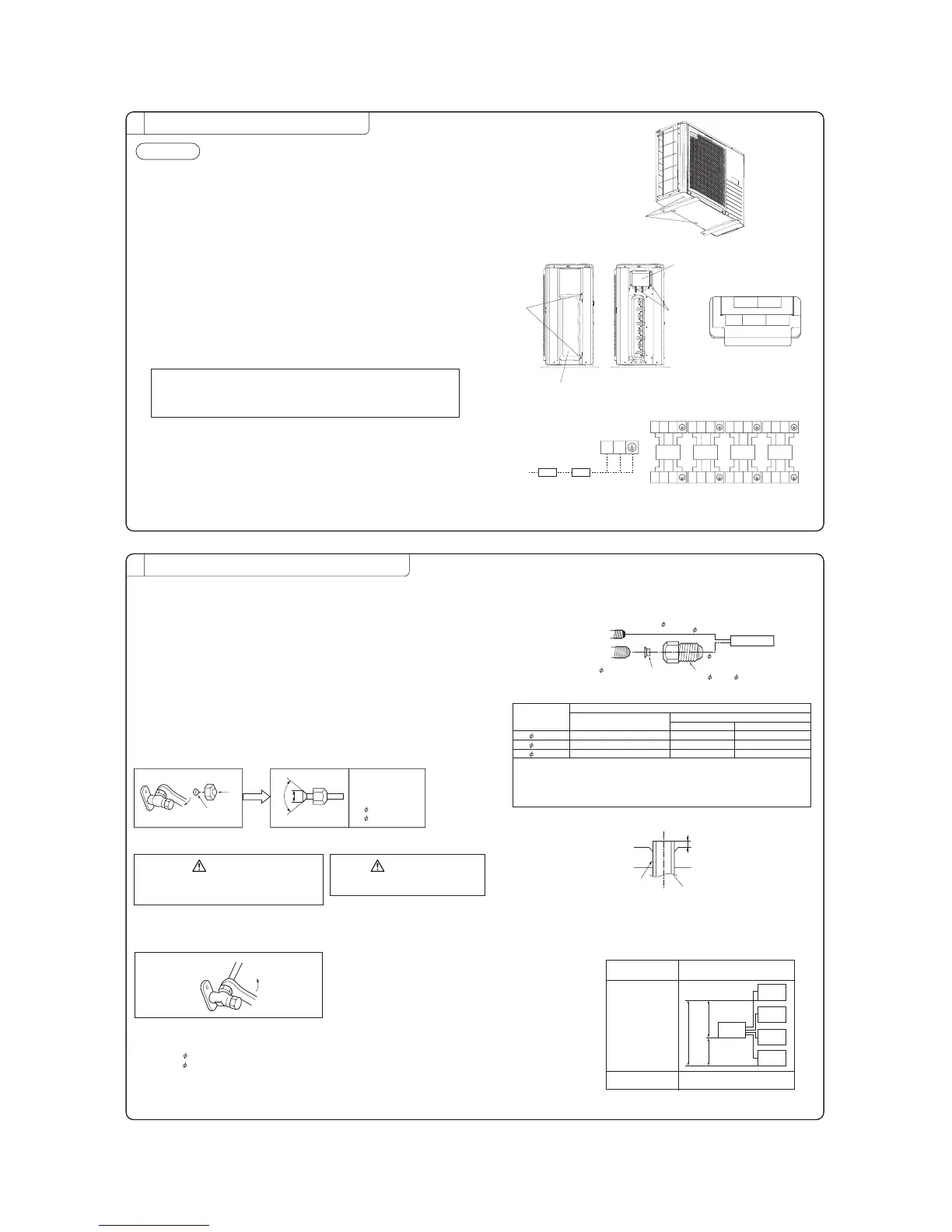

INSTALLATION OF OUTDOOR UNIT

2

Drainage

There are 3 holes in the bottom panel of the outdoor unit to drain condensation.

View of Terminal block

Install the outdoor unit so it will be horizontal.

Also, secure the legs of the unit to a firm foundation to prevent any instabilities.

Secure it firmly so the unit will not fall during earthquakes and from sudden gusts of wind.

In areas where the temperatures drop below 0˚C for several continuous days, do

not install a drain elbow. (water discharge could stop due to freezing.)

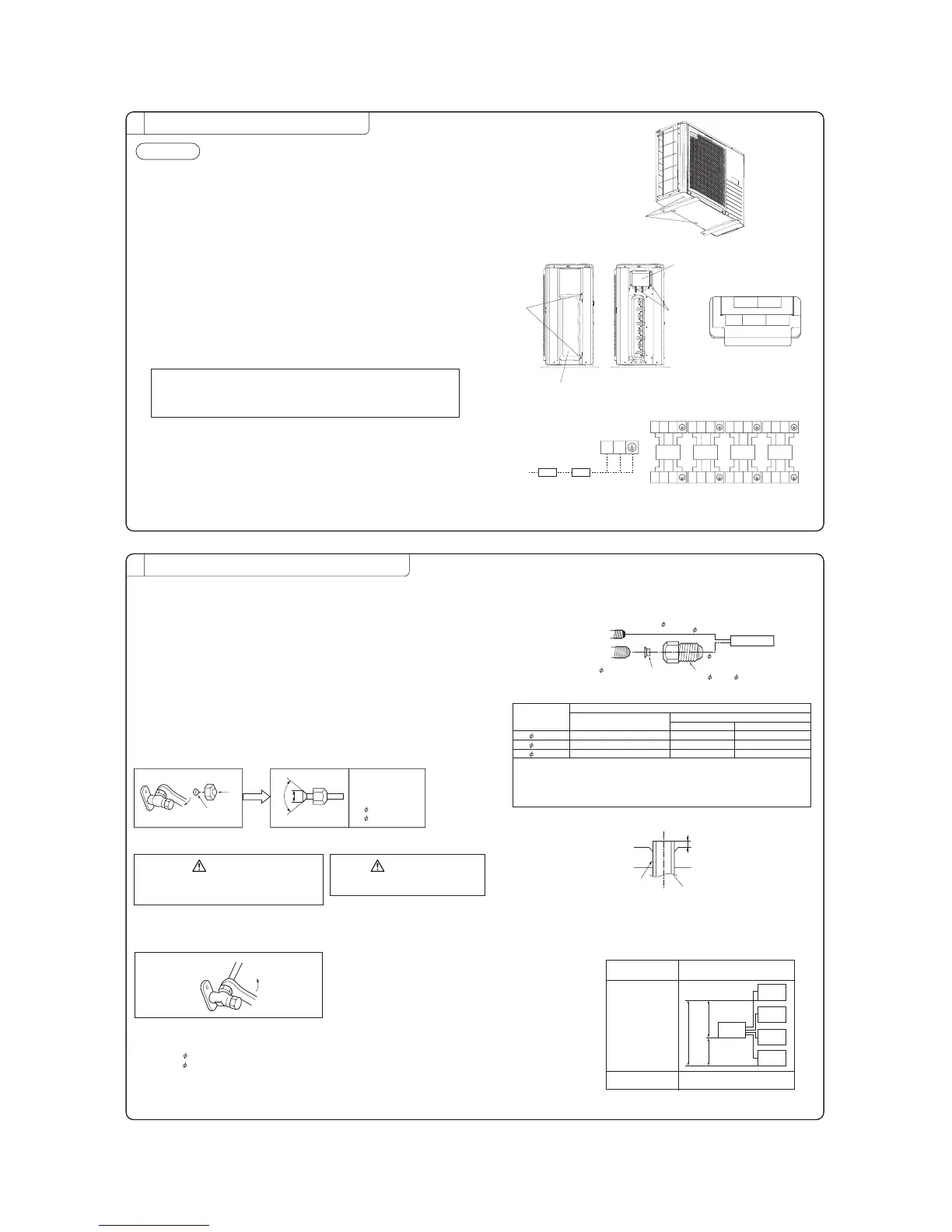

Connection of the power supply cable and the connecting cables

for indoor and outdoor units.

This multi-type room air conditioner receives its power from outside.

To ensure correct connections, mark each ends of the cables with number, A to D. It

is important to use the same number the corresponding cables and pipes.

An earth leakage breaker and a circuit breaker must be installed.

Their capacities are 25A.

①

Remove the service panel.(Remove the 2 sets screws of the service panel.)

Remove the terminal cover.(Remove the 2 sets screws of the terminal cover.)

②

③

⑤

④

Connect the power supply cable and the connection wire securely to the terminal block.

〔POWER SUPPLY CODE〕

CENELEC code for cables requiring fields cables. H05RNR3G4.0

〔INTERCONNECTING WIRING CODE〕

CENELEC code for cables requiring fields cables. H05RNR4G1.5

1) In wiring, make sure that the wire terminal numbers of outdoor unit terminal

block are match to the wire terminal numbers of indoor unit terminal block.

2) Terminal number A of the outdoor unit is used for A indoor unit and terminal

number B for B indoor unit respectively.

After connecting the wire, use wiring clamps to secure the wiring.

Fit the terminal cover and the service panel.

outdoor unit

1 2 31 2 3 1 2 3 1 2 3

1 2 3

1 2 3

1 2 3

unit A

unit B

unit C

unit A unit B

indoor unit

unit C

1 2 3

unit D

unit D

L N

Circuit

breaker

Earth

leakage

breaker

CONNECTION OF REFRIGERANT PIPINGS

3

Regarding the change in the sizes of gas side pipes (usage of the variable joints);

If a 5.0, 6.0 kw class indoor unit (gas side pipe 12.7) is going to be connected to the

operation valves (9.52), variable joints available as accessories must be applied to the

gas side operation valves.

[Examples of use of variable diameter joints]

Connection of indoor unit of Class 5.0 to A unit.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Operation

valveforroomA

Liquidsideoperationvalve(

6.35)

6.35pipe

5.0kw

Indoorunit

Gassideoperation

valve(

9.52)

Copperpacking

①Variablediameterjoint

(

9.52- 12.7)

12.7pipe

Use a flare tool designed for R410A ora conventional flare tool. Please note that

measurementB(protrusionfromtheflaringblock)willvarydependingonthetypeofa

flaretoolinuse.

If a conventional flare tool is used, please use a copper pipe gauge or a similar

instrumenttocheckprotrusionsothatyoucankeepmeasurementBtoacorrectvalue.

Copperpipe

diameter

Clutchtypeflaretoolfor

R410A

Conventional

(

R22

)

flaretool

Clutchtype Wingnuttype

MeasurementB

(

mm

)

6.35 0.0〜0.5 1.0〜1.5 1.5〜2.0

9.52 0.0〜0.5 1.0〜1.5 1.5〜2.0

12.7 0.0〜0.5 1.0〜1.5 2.0〜2.5

Securely fit the copper packing between the operation valve and the variable

diameter joint to prevent shifting.

[Connection of pipes]

NOTE

Cover the pipes with tape so that dust and sand do not enter the pipe until they are

When connecting the pipes to the outdoor unit, be careful about the discharge of fluorocarbon

Make sure to match the pipes between the indoor unit and the outdoor unit with the

connected.

gas or oil.

correct operation valves.

Outdoor

Press

Remove

A

90±0.5°

Dimension A

Liquid side 9.1dia.

Gas side

9.52 : 13.2dia

12.7 : 16.2dia.

○

Remove the flared nuts.

(on both liquid and gas sides)

○Install the removed flared nuts to the pipes

to be connected, then flare the pipes.

Do not apply excess torque to the flared nuts.

Otherwise, the flared nuts may crack depending

on the conditions and refrigerant leak may occur.

CAUTION

Donotapplyrefrigeratingmachine

oiltotheflaredsurface.

CAUTION

Measurement B

Flaring

block

Copper pipe

Outdoor

Connection

Liquid side

Gas side

When the total refrigerant pipe lenght for all the

rooms exceeds the lenght of the uncharged pipe

(40m), additional refrigerant is required.

(If 40m or less, additional charge is not required.)

Additional charge amount per meter = 20g/m

●

Ensure that there are no gas leaks from the pipe

joints by using a leak detector or soap water.

Gas Leakage Test

●

○Connect the pipes on both liquid and gas sides.

○Tighten the nuts to the following torque.

Liquid side : 14.0

〜18.0N・m

(

1.4〜1.8kgf・m

)

Gas side (

9.52): 33.0〜42.0N・m (3.3〜4.2kgf・m)

(

12.7): 49.0〜61.0N・m (4.9〜6.1kgf・m)

piping length

hight difference

length of chargeless

refrigerant pipe

one indoor unit MAX 25m

all indoor unit MAX 70m

40m

MAX

25m

MAX 20m

MAX 20m

outdoor

unit

indoor

unit

indoor

unit

indoor

unit

indoor

unit

[Limit]

4

AIR PURGING

NOTE : Fully open the operation valves (on both liquid and gas sides) after completing air purging.

● Since the system uses service ports differing in diameter from those found

on the conventional models, a charge hose (for R22) presently in use is not

applicable. Please use one designed specifically for R410.A.

●Please use an anti-reverse flow type vacuum pump adapter so as to prevent

vacuum pump oil from running back into the system. Oil running back into

an air-conditioning system may cause the refrigerant cycle to break down.

● Remove the cap on both gas and liquid sides before starting operation.

● After completing the operation, do not forget to tighten the cap (gas may leak).

●Conduct air purging for all connected indoor units.

Procedure

(1) Secure all flare nuts on both indoor and outdoor sides to

prevent leaks from the pipes.

(2) Connect the operation valves, charge hose, manifold

valve and vacuum pump as shown in the right figure.

(3) Fully open the handle Lo for the manifold valve, and

pump a vacuum for 15 minutes. Ensure that the meter

is indicating -0.1MPa (-76cmHg).

(4) After vacuuming, fully open the operation valve (both

liquid and gas sides) with a hexagon wrench.

(5) Remove the charge hose from service port.

(6) Repeat the above steps (1) ~ (5) for all connected indoor units.

(7) Ensure that there are no gas leaks from the joints in the indoor and outdoor units.

Open

Open

5

HEAT INSULATION FOR JOINTS

Heat insulation for joints

Vinyl

tape

Position so

the slit

comes on top.

Cover the joint with

insulation material

for the indoor unit

and tape it.

Pipe clamp

Pipes

Crossover wires

Exterior tape

Drain hose

Tapping screw

Apply exterior tape and

shape along the place

where the pipes will be

routed. Secure to the wall

with a pipe clamp. Be

careful not to damage the

pipes and the wires.

7

BEWARE OF WRONG CONNECTIONS IN

REFRIGERANT PIPING AND WIRING.

●Make sure to match the piping and wiring from each unit to the

●Be careful because if connections are wrong, normal operation

cannot be achieved and may damage the compressor.

outdoor unit.

[Correct connections]

[Example of wrong connections]

Piping

Wiring

Indoor unit

Indoor unit

D unit

C unit

B unit

A unit

Outdoor

unit

D unit

C unit

B unit

A unit

Outdoor

unit

D

C

A

B

D

C

A

B

EARTHING WORK

○Earth work shall be carried out without fail in order to prevent electric

shock and noise generation.

○The connection of the earth cable to the following substances causes

dangerous failures, therefore it shall never be done. (City water pipe,

Town gas pipe, TV antenna, lightning conductor, telephoneline, etc.)

Check the following points again after completion of the installation, and before

turning on the power.

Conduct a test run again and ensure that the unit operates properly.

At the same time, explain to the customer how to use the unit and how to take

care of the unit following the installation manual.

If the compressor does not operate after the operation has started, wait for 5-10

minutes. (This may be due to delayed start.)

(Three-minute restart preventive timer)

When the air conditioner is restarted or when changing the operation, the unit will

not start operating for approximately 3minutes. This is to protect the unit and it is

not a malfunction.

After installation

Test run

□

The power supply voltage is correct as the rating.

□No gas leaks from the joints of the operation valve.

□Power cables and crossover wires are securely fixed to the terminal board.

□Each indoor and outdoor unit is properly connected (no wrong wiring or piping).

□Operation valve is fully open.

□Refrigerant has been additionally charged (when the total pipe length exceeds

the refrigerant charged pipe length).

□The pipe joints for indoor and outdoor pipes have been insulated.

□Earthing work has been conducted properly.

□Air conditioning and heating are normal.

□No abnormal noise.

□Water drains smoothly.

□Protective functions are not working.

□Operation of the unit has been explained to the customer.

□The remote control is normal.

Operation of indicator lamps

INDICATION LAMP

LED E (1)

1 TIME FLASH

2 TIME FLASH

3 TIME FLASH

4 TIME FLASH

5 TIME FLASH

6 TIME FLASH

7 TIME FLASH

8 TIME FLASH

LIGHT ON

FOUR SEC LIGHT

AND

FOUR SEC OFF

COLOR

RED

SELF DIAGNOSIS FUNCTION BY LED E

FUNCTION

WARNING LAMP

CURRENT CUT

TROUBLE OF OUTDOOR UNIT

OVER CURRENT

TRANSMISSION ERROR IN OUTDOOR UNIT PCB

OVER HEAT OF COMPRESSOR

ERROR OF SIGNAL TRANSMISSION

LOCK OF COMPRESSOR

SENSOR ERROR (EXCEPT DISCHARGE PIPE SENSOR)

OUTDOOR FAN MOTOR ERROR

DISCHARGE PIPE SENSOR ERROR

Installation test check points

6

TEST RUN AND HANDLING INSTRUCTIONS

drain hole

Terminal cover

Service panel

Screw

Operation valve

for room D

Operation valve

for room C

Operation valve

for room B

Operation valve

for room A

tightening torque (N·m)

Operation valve cap

tightening torque (N·m)

Check joint blind nut

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

20

30

25

35

10

12

Operation valve size

(mm)

Securely tighten the operation valve cap and the check joint blind nut after adjustment.

(three-way valve)

Charge hose

(Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge Manifold

(Designed specifically for R410A)

Handle Hi.

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Operation Valve

Operation Valve

(two-way valve)

Operation Valve

Cap

Operation Valve

Cap

Screw

unit A unit B

unit C

unit D

POWER

SUPPLY

A

RPC012A913

Loading...

Loading...