2. Installation (general specifications)

As for installation of the input/output extension blocks, special

adapters and expansion boards, refer to FX3U Series User's Manual

- Hardware Edition.

2.1 Generic specifications [Main unit]

*1

For dielectric with stand voltage test and insulation

resistance test of each product, refer to the following manual.

→ Refer to FX3U Series User's Manual - Hardware Edition.

*2 For common grounding, refer to section 3.3.

*3 The PLC cannot be used at a pressure higher than the

atmospheric pressure to avoid damage.

2.2 Installation location

Install the PLC in an environment conforming to the generic

specifications (section 2.1), installation precautions and notes.

INSTALLATION

PRECAUTIONS

•

Use the product within the generic environment specifications

described in section 2.1 of this manual.

Never use the product in areas with excessive dust, oily smoke,

conductive dusts, corrosive gas (salt air, Cl

2

, H

2

S, SO

2

or NO

2

),

flammable gas, vibration or impacts, or exposed to high

temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire,

malfunctions, deterioration or damage may occur.

•

Do not touch the conductive parts of the product directly to avoid

failure or malfunctions.

•

Install the product securely using a DIN rail or mounting screws.

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to

the PC board, thereby causing nonconformities.

• When drilling screw holes or wiring, make sure cutting or wire

debris does not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or

malfunctions.

• Be sure to remove the dust proof sheet from the PLC's

ventilation port when installation work is completed. Failure to

do so may cause fire, equipment failures or malfunctions.

• Connect the extension cables, peripheral device cables, input/

output cables and battery connecting cable securely to their

designated connectors.

Unsecured connection may cause malfunctions.

• Turn off the power before attaching or detaching the following

devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boards and

special adapters

- Extension units/blocks and the FX Series terminal block

- Battery and memory cassette

Notes

• When a dust proof sheet is supplied with an extension unit/

block, keep the sheet applied to the ventilation slits during

installation and wiring work.

• To prevent temperature rise, do not install the PLC on a floor, a

ceiling or a vertical surface.

Install it horizontally on a wall as shown in section 2.2.

• Keep a space of 50 mm (1.97”) or more between the unit main

body and another device or structure (part A). Install the unit as

far away as possible from high-voltage lines, high-voltage

devices and power equipment.

WIRING

PRECAUTIONS

• Cut off all phases of the power supply externally before

installation or wiring work in order to avoid damage to the

product or electric shock.

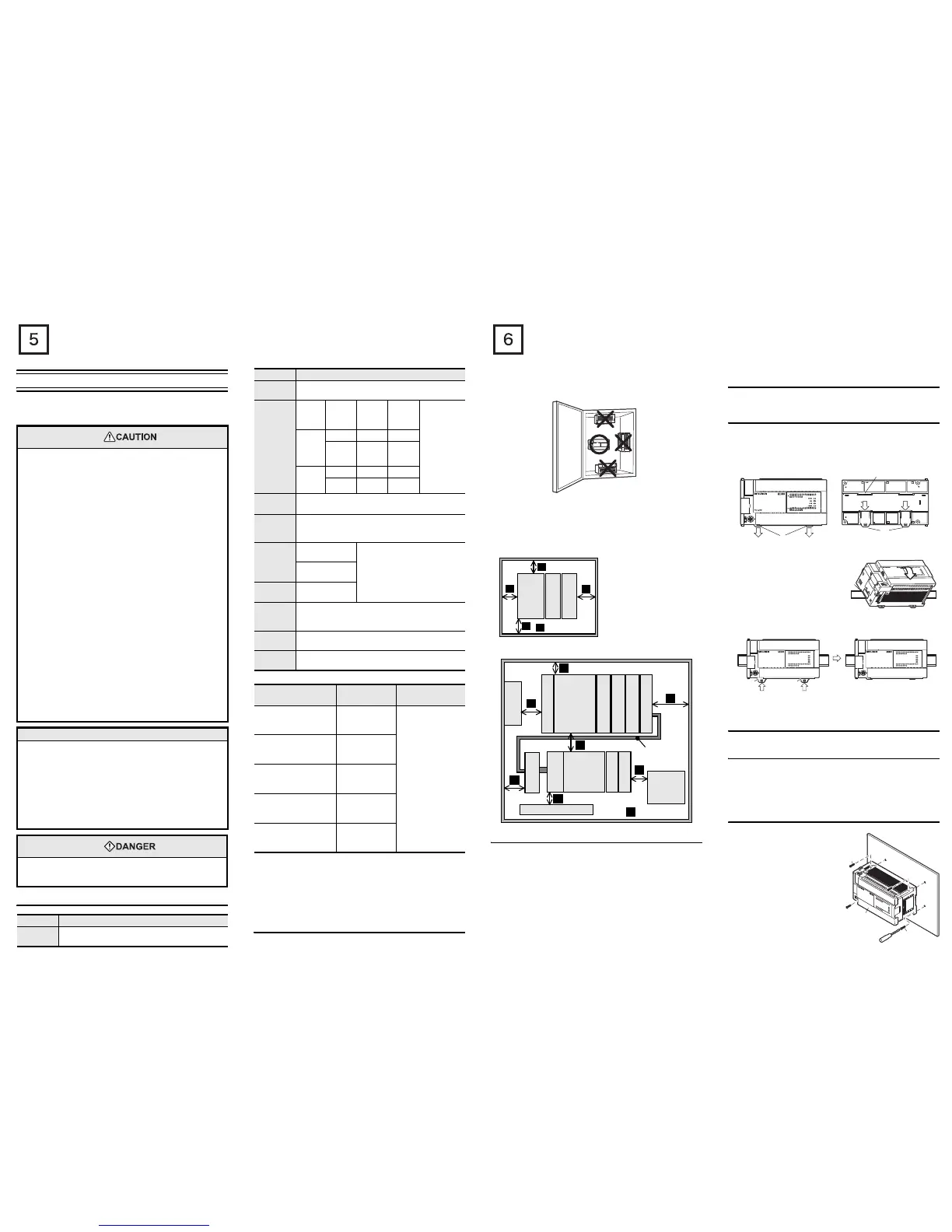

Item Specification

Ambient

temperature

0 to 55°C (32 to 131°F) when operating and -25 to

75°C (-13 to 167°F) when stored

Ambient

humidity

5 to 95%RH (no condensation) when operating

Vibration

resistance

Fre-

quency

(Hz)

Accele-

ration

(m/s

2

)

Half

amplitude

(mm)

Sweep Count

for X, Y, Z: 10

times

(80 min in

each direction)

When

installed

on DIN

rail

10 to 57 - 0.035

57 to 150

4.9 -

When

installed

directly

10 to 57 - 0.075

57 to 150

9.8 -

Shock

resistance

147 m/s

2

Acceleration, Action time: 11ms, 3 times by

half-sine pulse in each direction X, Y, and Z

Noise

resistance

By noise simulator at noise voltage of 1,000 Vp-p,

noise width of 1 µs, rise time of 1 ns and period of 30

to 100 Hz

Dielectric

withstand

voltage

*1

1.5kV AC for one

minute

Between each terminals

*1

and

ground terminal

500V AC for one

minute

Insulation

resistance

*1

5MΩ or more by

500V DC megger

Grounding

Class D grounding (grounding resistance: 100 Ω or

less) <Common grounding with a heavy electrical

system is not allowed.>

*2

Working

atmosphere

Free from corrosive or flammable gas and excessive

conductive dusts

Working

altitude

<2000m

*3

Terminal

Dielectric

strength

Insulation

resistance

Between power supply

terminal (AC power) and

ground terminal

1.5 kV AC for

one minute

5MΩ or more by

500V DC megger

Between power supply

terminal (DC power) and

ground terminal

500V AC for

one minute

Between input terminal

(24V DC) and ground

terminal

500V AC for

one minute

Between output terminal

(relay) and ground

terminal

1.5 kV AC for

one minute

Between output terminal

(transistor) and ground

terminal

500V AC for

one minute

Item Specification

For more details, refer to FX

3U

Series User's Manual - Hardware

Edition.

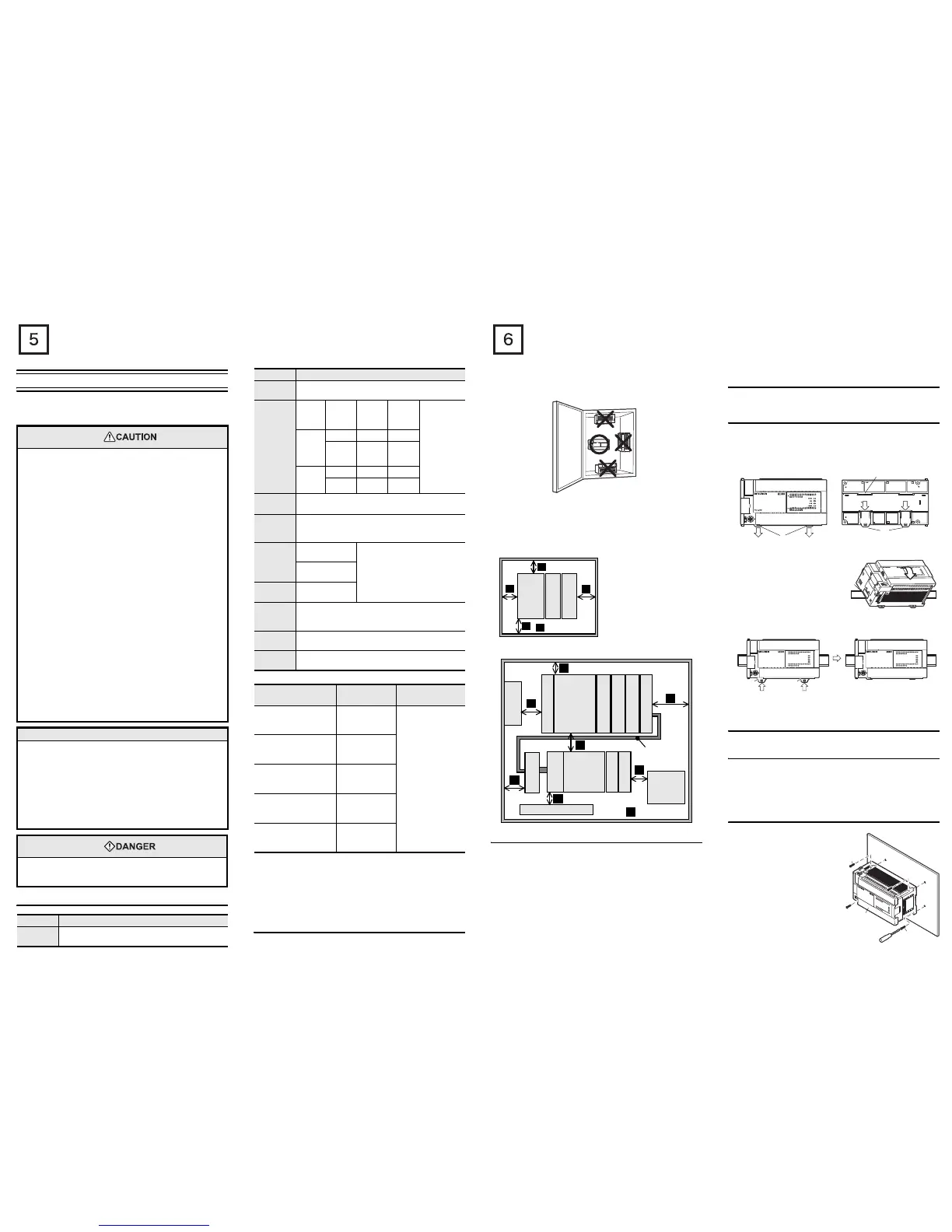

Installation location in enclosure

Space in enclosure

Extension devices can be connected on the left and right sides of the

main unit of the PLC.

If you intend to add extension devices in the future, keep necessary

spaces on the left and right sides.

2.2.1 Affixing The Dust Proof Sheet

The dust proof sheet should be affixed to the ventilation port before

beginning the installation and wiring work.

→ For the affixing procedure, refer to the instructions on the

dust proof sheet.

Be sure to remove the dust proof sheet when the installation and

wiring work is completed.

2.3 Procedures for installing to and detaching from

DIN rail

The main unit can be installed on a DIN46277 rail [35 mm (1.38”)

wide].

2.3.1 Installation

1) Connect the expansion boards and special adapters to the main

unit.

2) Push out all DIN rail mounting hooks (below fig.A)

3) Fit the upper edge of the DIN rail

mounting groove (right fig.C)

onto the DIN rail.

4) Lock the DIN rail mounting hooks (below fig.D) while pressing the

PLC against the DIN rail.

2.4 Procedures for installing directly (with M4

screws)

The product can be installed directly on the panel (with screws).

2.4.1 Mounting hole pitches

Refer to the External Dimensions (section 1.2) for the product's

mounting hole pitch information.

As for the details of the mounting hole pitches for extension unit/

block and special adapters, refer to the following manual.

→ Refer to FX3U Series User's Manual - Hardware Edition.

2.4.2 Installation

1) Make mounting holes in the

mounting surface referring to

the external dimensions

diagram.

2) Fit the main unit (A in the right

figure) based on the holes, and

secure it with M4 screws (B in

the right figure).

The mounting hole pitches and

number of screws depend on

the product. Refer to the

external dimensions diagram.

FX

3U

-48MFX

3U

-48M

≥

50mm (1.97")

A

A

A

A

A

FX

3U

Series

main

unit

FX

2N

-16EX

-ES/UL

FX

2N

-16EYT

-ESS/UL

Configuration without extension cable

Another equipment

Another

equipment

Extension

cable

·FX

0N

-65EC

·FX

0N

-30EC

Another

equipment

A

A

A

A

A

A

A

A

≥

50mm (1.97")

Configuration in 2 stages with extension cable

FX

2N

-CNV-BC

Input/output

powered

extension

unit

FX

2N

-16EX

-ES/UL

FX

2N

-10PG

FX

2N

-8AD

FX

3U

Series

main unit

FX

2N

-16EX-ES/UL

FX

2N

-16EYT-ESS/UL

FX

2N

-4AD

FX

2N

-16EYR-ES/UL

FX

3U

-4AD-ADP

A

2)2)

2)

A

2)

C

C

RUN

STOP

FX

Loading...

Loading...