OPERATION

2^

Adjustment

of

needle

threads

tension

release

assembly

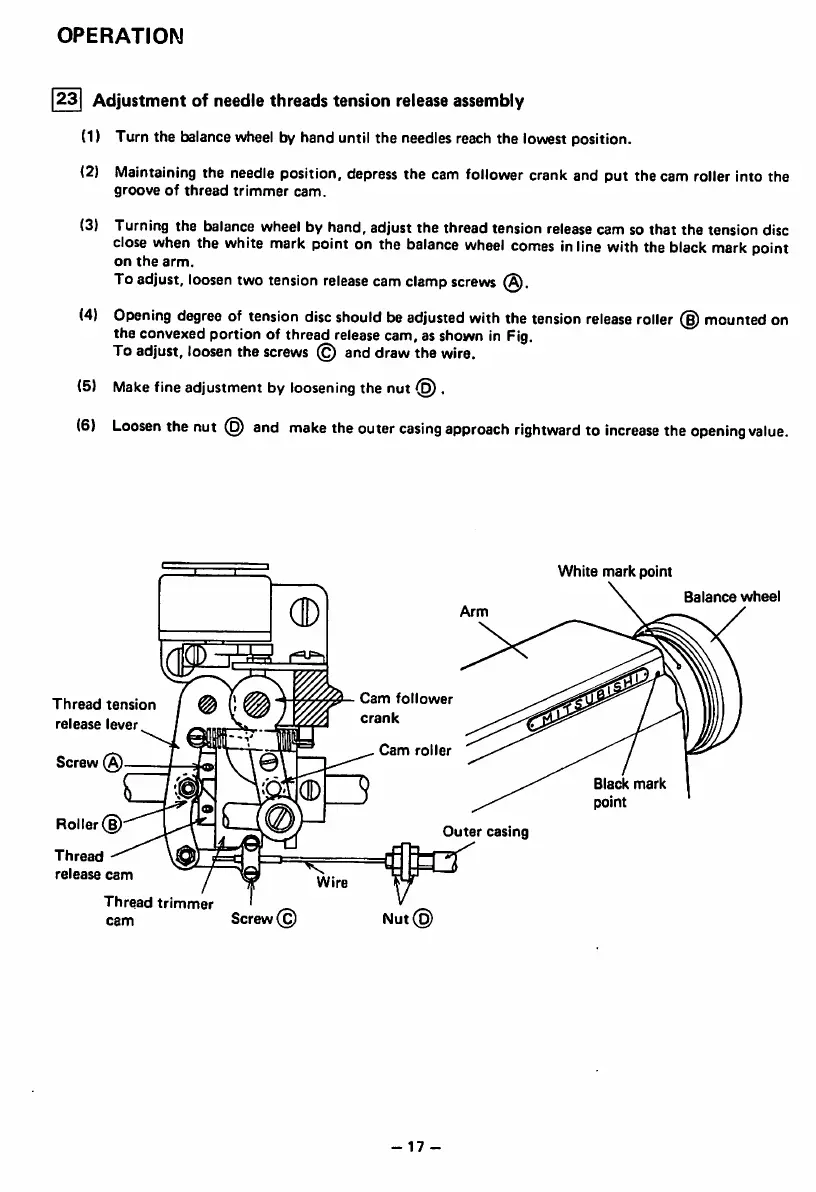

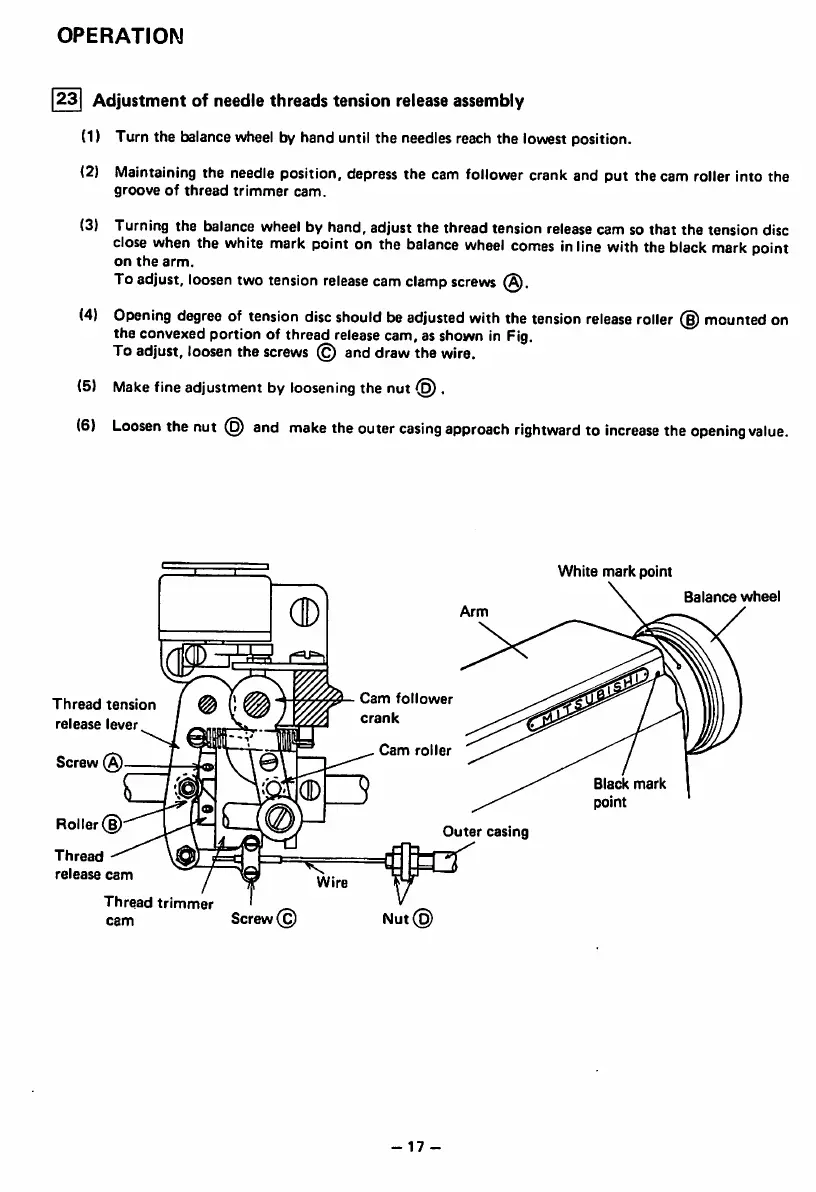

(1) Turn the balance

wheel

by hand until the needlesreachthe lowestposition.

(2)

Maintaining

the

needle

position,

depress

the cam follower crank and put the cam rollerinto the

groove

of

thread

trimmer

cam.

(3) Turning the balance wheel by hand, adjust the thread tension releasecam so that the tension disc

close

when

the

white

mark

pointon the

balance

wheel

comes

in

line

withthe

black

mark

point

on

the

arm.

To

adjust,

loosen

two

tension

release

cam

clamp

screws

@.

(4)

Opening

degree

of

tension

disc

should

be

adjusted

with

the

tension

release

roller

(g)

mounted

on

the convexed portion of thread release cam, as shown in Fig.

To adjust, loosen the screws (g) and draw the wire.

(5)

Make

fine

adjustment

by

loosening

thenut{§),

(6)

Loosen

the

nut

(5)

and

make

the

outer

casing

approach

rightward

to

increase

the

opening

value.

Thread

tension

release

lever

Screw(M

Roller

(g)

Thread

release

cam

(D

Thread

trimmer

cam

Screw

©

Arm

Cam

follower

crank

Cam

roller

Outer

casing

-17-

White

mark

point

Black

mark

point

Balance

wheel

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...