DAILY INSPECTION A-7

5. INSPECTION OF THE CHUCK

<Daily oiling>

To maintain high chuck accuracy over a prolonged period, it is necessary to supply lubricating oil.

Improper lubrication will cause the following problems.

• Faulty operation at low hydraulic pressure

• Insufficient gripping force

• Low gripping accuracy

• Abnormal wear

• Seizure

To avoid those problems, be sure to supply lubricating oil properly.

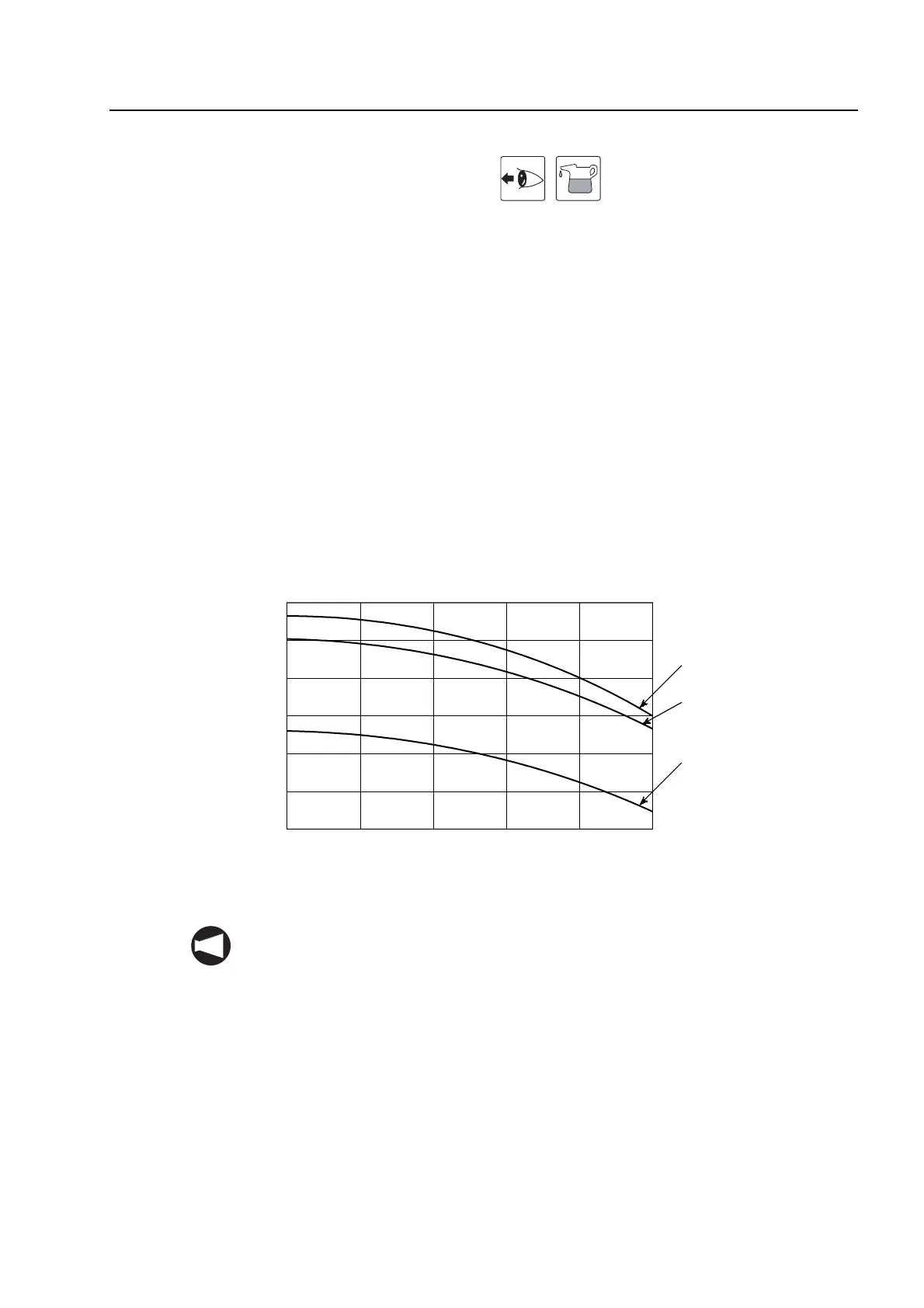

The diagram below indicates how greasing influences chuck gripping force by showing the

relationship between the chuck gripping force and the spindle speed.

Example) SL-25MC, Chuck HOIMA10A6 (Howa), Cylinder HH4C-125 (Howa)

The diagram above is for reference purposes only. The actual gripping force will vary

depending on the machine model, chuck and cylinder used by the customer. In any case,

however, the chuck gripping force is reduced if the chuck is not greased properly. To

obtain the correct chuck gripping force, it is necessary to grease the chuck at least once a

day, before starting operation.

<Daily cleaning>

At the end of each day, when operation is completed, clean the chuck body and slideways.

44.1

14.7

19.6

24.5

29.4

34.3

39.2

0 500 1000 1500 2000 2500

Spindle Speed (min

−1

)

Gripping Force (kN (lbf))

Before greasing

After greasing

Greasing after

disassembling and cleaning

NOTE

Loading...

Loading...