DAILY INSPECTION A-5

4. SUPPLYING OIL IN DAILY MAINTENANCE

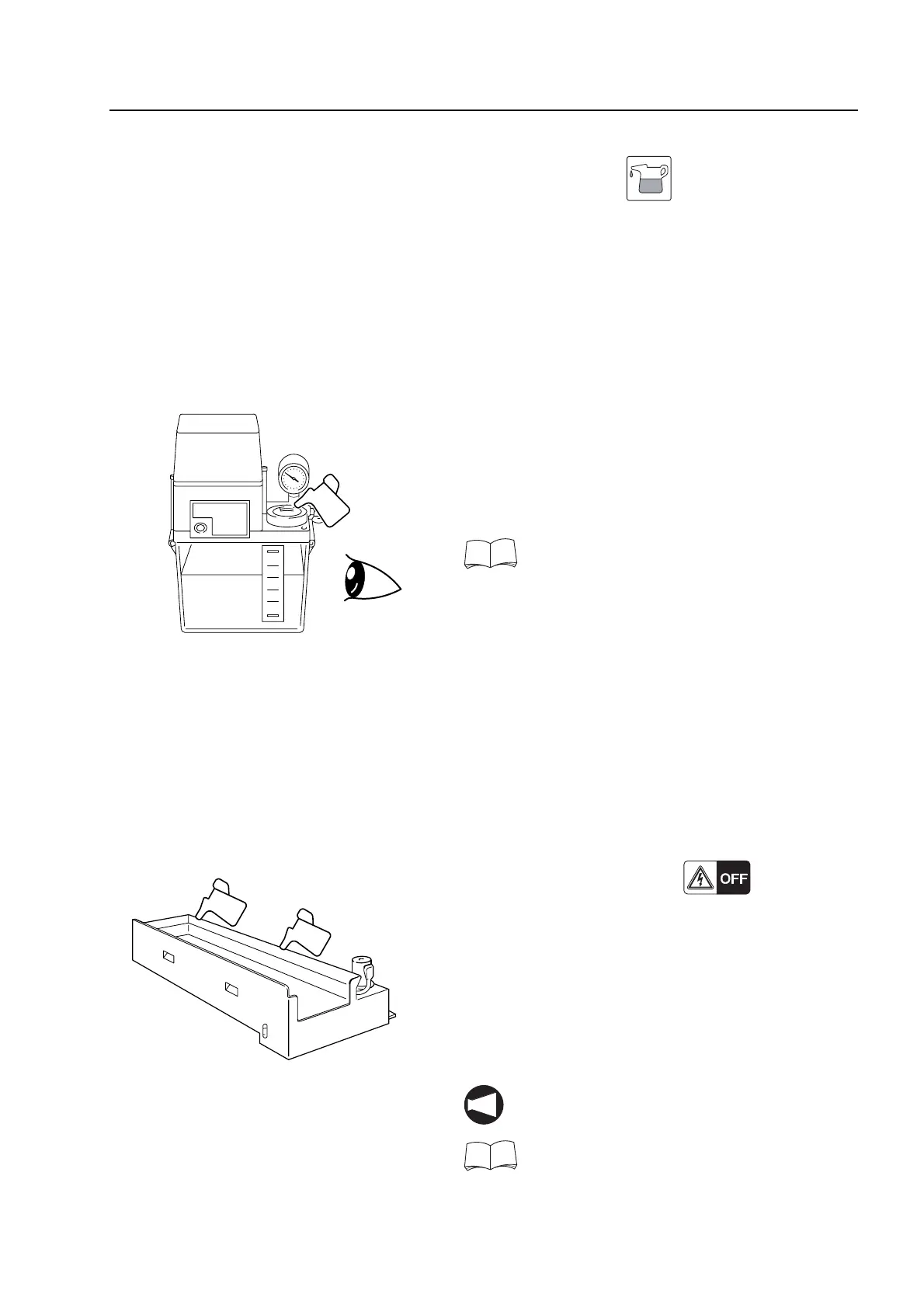

4.1 Supplying Oil to the Lubricating Oil Tank

If the oil level in the lubricating oil tank drops, an alarm indication is given. If this low lubricating oil

level alarm is given, supply lubricating oil.

<Procedure>

(Example: Showa Yuki 2 L)

1) Check the volume of oil in the lubricating oil tank with

the oil level gage installed on the lubricating oil tank.

2) Remove the cap on the oil supply port.

3) Supply the specified lubricating oil by using the oil jug

while checking the oil level with the oil level gage.

For the name and volume of the cooling oil,

refer to the OILING CHARTS in the

MAINTENANCE INFORMATION published

separately.

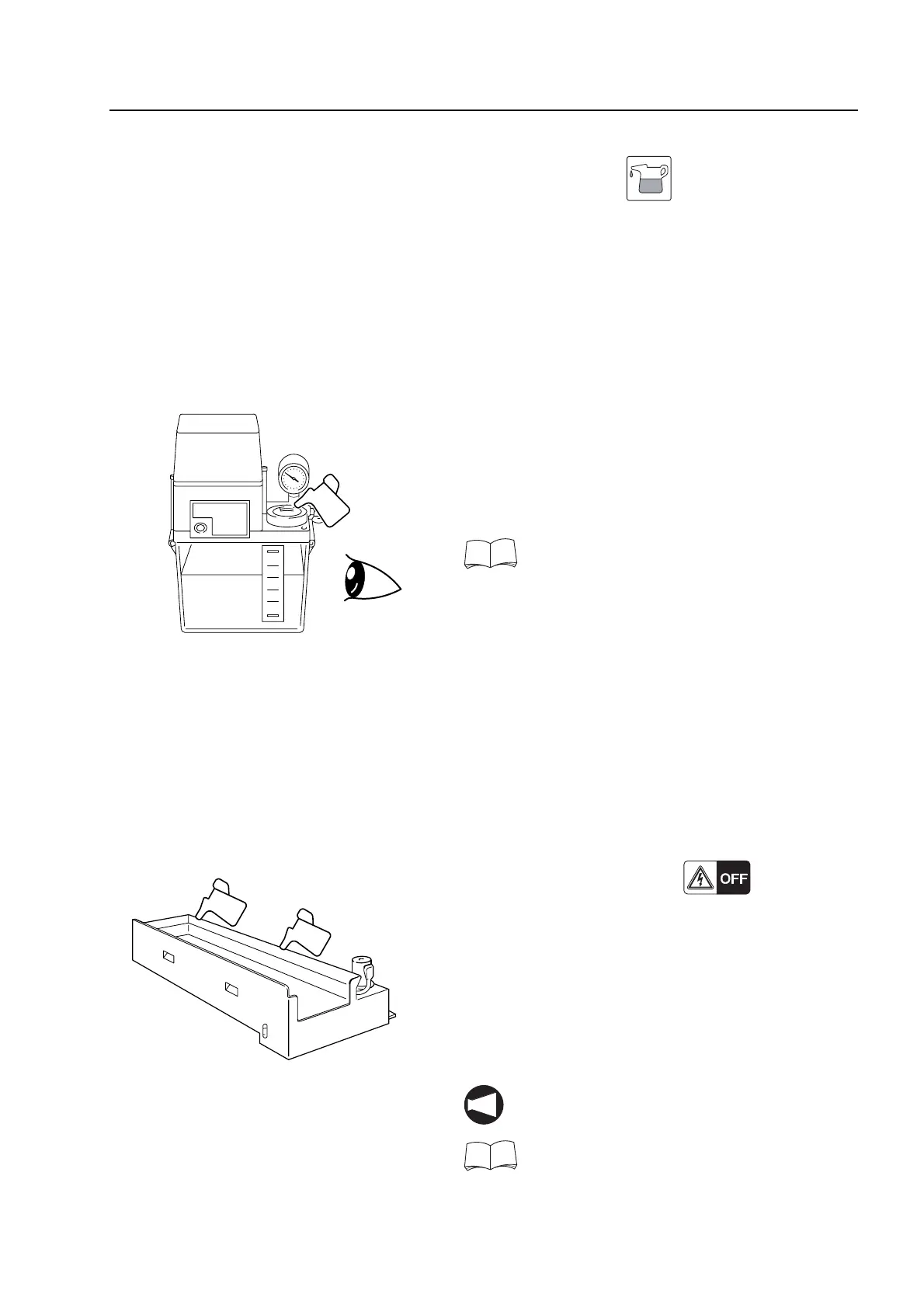

4.2 Supplying Coolant to the Coolant Tank

If the coolant level drops, an insufficient amount of coolant is supplied to the cutting tool. If cutting

is continued under such conditions, accuracy will be impaired and tool life shortened. If coolant

level drops, supply coolant to the coolant tank.

<Procedure>

1) Turn OFF the main power.

2) Wait until the coolant level is stabilized after all of the

remaining coolant inside machine is returned to the

coolant tank.

3) Check the volume of coolant in the coolant tank using

the oil level gage.

4) When coolant level is close to the red line on the oil

level gage

Supply coolant to the red line on the oil level gage.

Do not fill above the red line.

For the capacity of the coolant tank, refer to the

OILING CHARTS in the MAINTENANCE

INFORMATION published separately.

NOTE

Loading...

Loading...