Motortronics

- 9 -

XLS Series Solid State Soft Starter 39 - 1250A

5.1 Introduction

It is best to operate the motor at its full load starting condition to

achieve the proper time, torque and ramp settings. Note that the

potentiometers have a turning range of 3/4 revolution. Forcing the

potentiometer beyond this range will damage the unit. Initial settings

are set to accommodate most motor conditions. TRY INITIAL

SETTINGS FIRST.

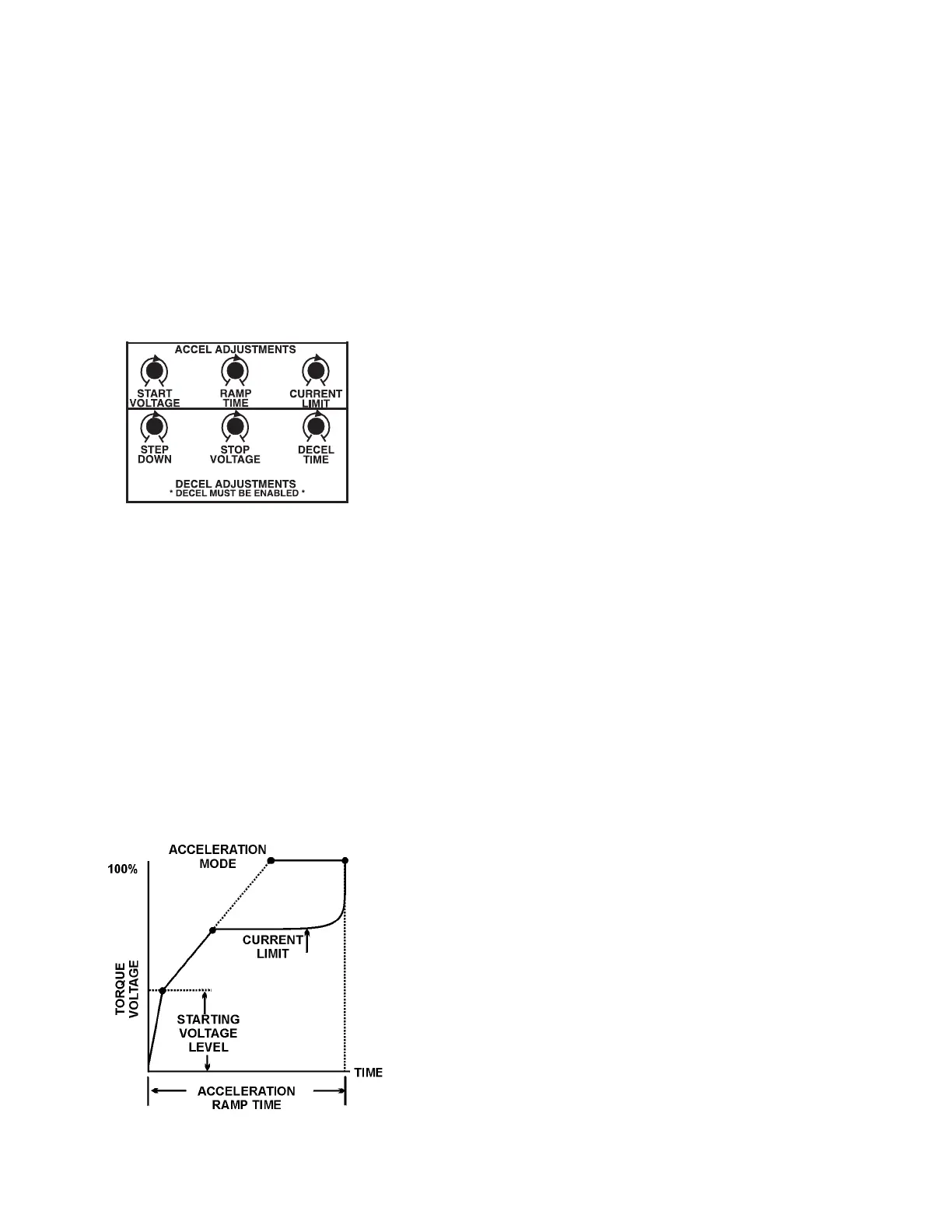

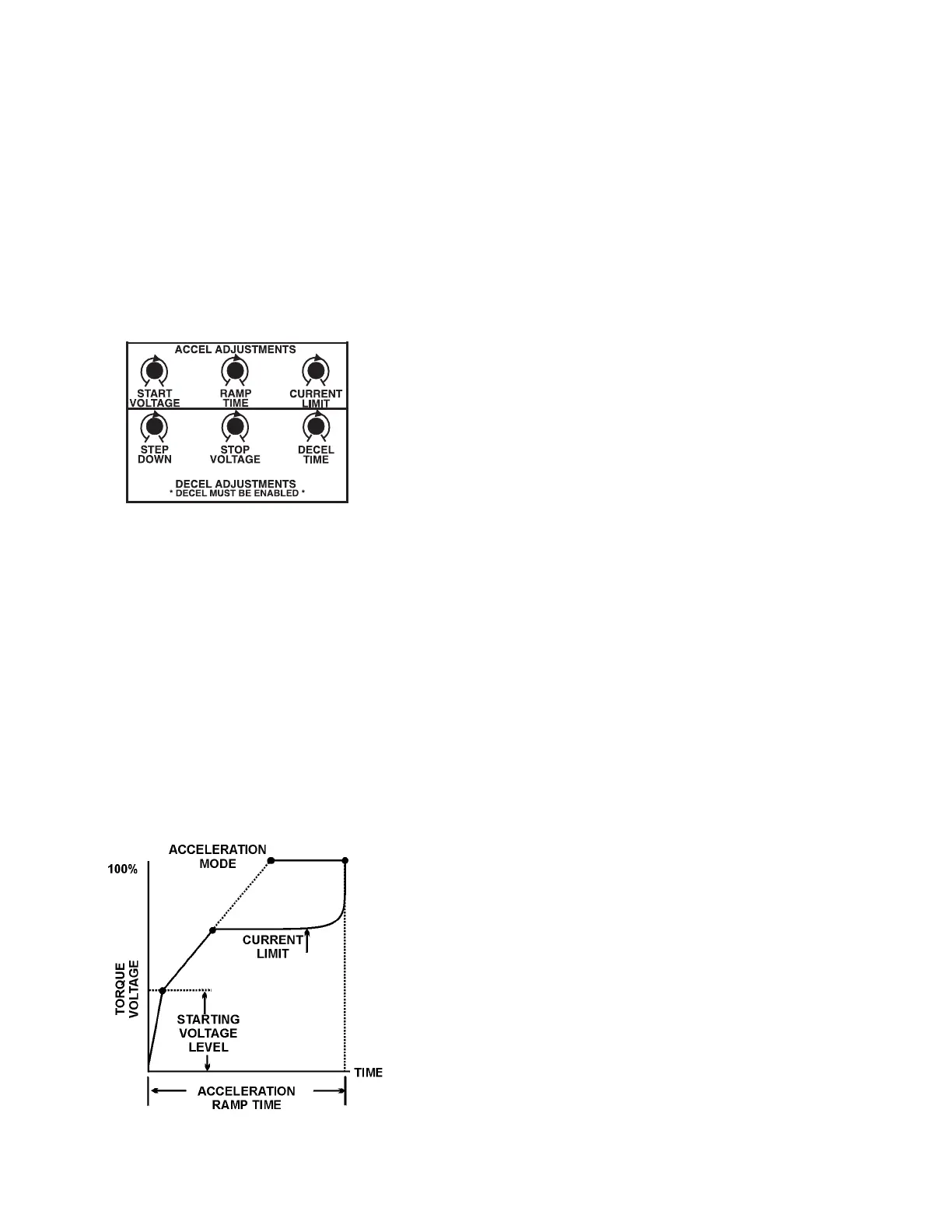

5.2 Acceleration Adjustments

The unit is set at the factory with typical starting characteristics that

perform well in most applications. When the system is ready to start,

try the initial unit settings. If the motor does not come up to speed,

increase the current limit setting. If the motor does not start to turn as

soon as desired, raise the starting voltage adjustment. The unit has

three accel adjustments. Adjustment description and procedures are

described as follows:

5.2.1 Starting Voltage Adjustment/Rotation Check

Factory Setting = 60% of line voltage

Range = 0% - 100% of line voltage

Starting voltage adjustment changes the initial starting voltage level to

the motor. Start voltage is increased by rotating the starting voltage

potentiometer clockwise. Turn dip switch 3 to the “OFF” position,

disabling the ramp function and allowing starting voltage adjustment.

This will permit adjustment of the starting voltage without activating

the ramp. Turn the starting voltage potentiometer FCCW (fully counter-

clockwise). Apply power to the XLS and give the start command.

Observe that the motor does not rotate. Slowly increase the start

voltage by turning the potentiometer in a clockwise direction until the

motor begins to rotate. When the motor begins to rotate, give a stop

command and remove both line and control voltage. Reset dip switch

3 for the “ON” position to re-enable the ramp function. The minimum

effective starting voltage is now set. Do not leave dip switch 3 in

the off position!

Note:

Use this time to check the direction of rotation without full

speed operation.

5.2.2 Ramp Time Adjustment

Factory Setting = 10 sec.

Range = 0 - 60 sec.

Ramp time adjustment changes the amount of time it takes to reach

the current limit point or full voltage if the current limit point was not

reached. Acceleration time (ramp) can be increased by rotating the

ramp time potentiometer in a clockwise direction. The ramp time

adjustment is made after the starting torque has been set. Set the

ramp time potentiometer by slowly rotating it until the desired ramp

time is reached. The unit should be stopped and restarted to see if the

desired acceleration time has been achieved

Note:

Refer to your motor manual for the maximum number of starts

allowed by the manufacturer and do not exceed the recommended

number.

Detail of Operator Interface Module

Chapter 5 - Adjustments

Loading...

Loading...