Page 17 mrcool.com

Unit Installation

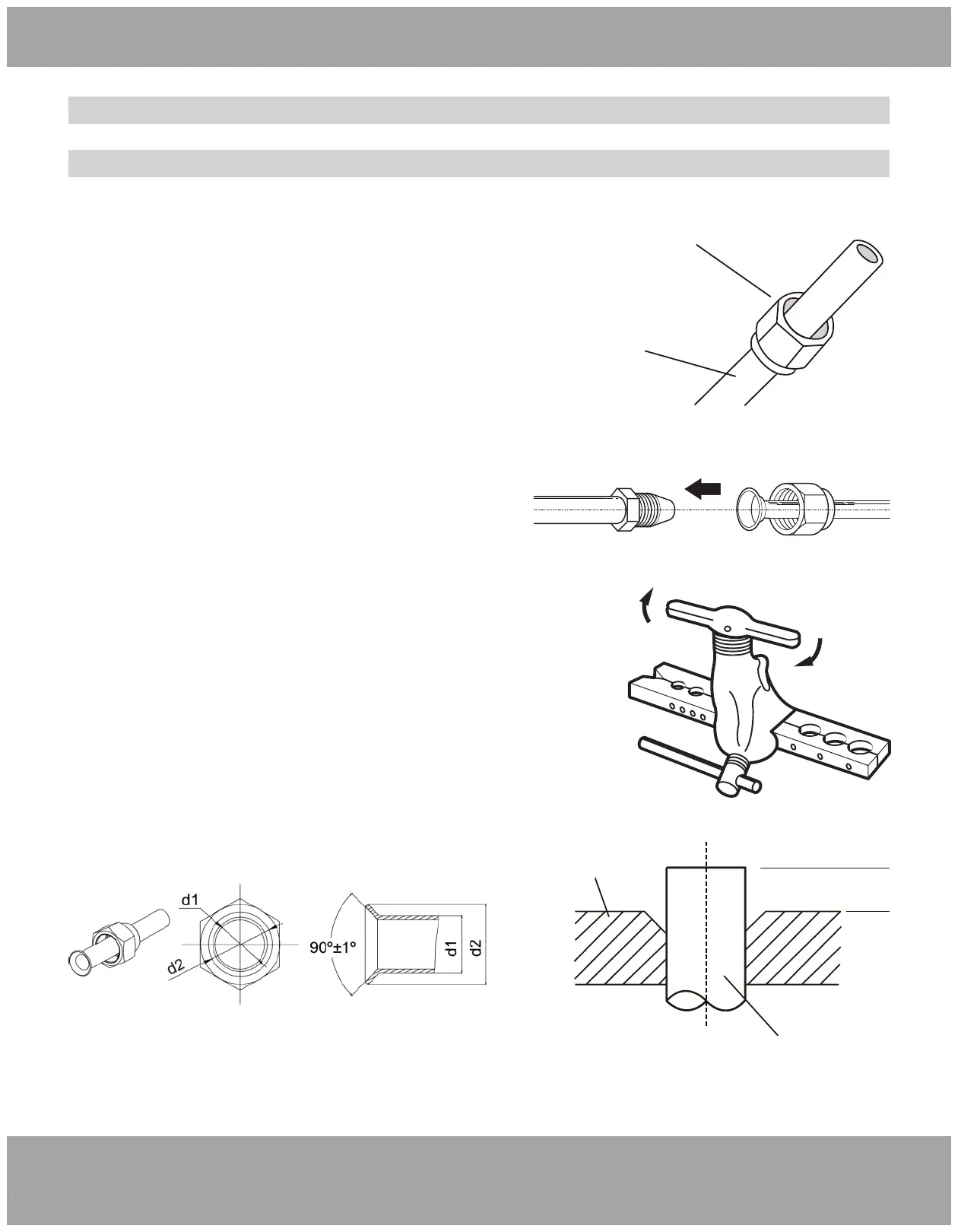

Flare nut

Copper pipe

Fig. 2.11

Fig. 2.12

Fig. 2.14

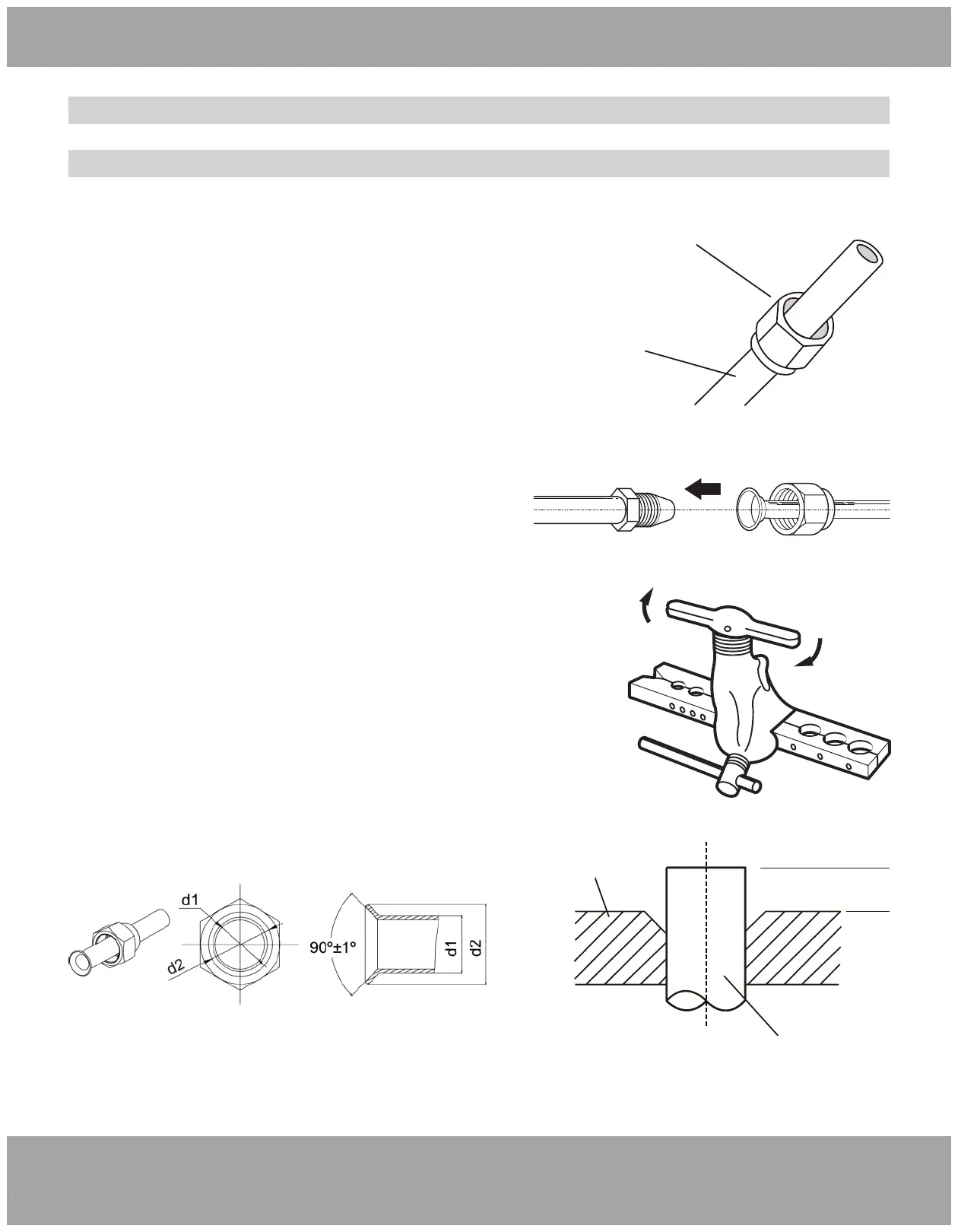

PIPING EXTENSION BEYOND FLARE FORM

Flare form

Pipe

A

A = ~1/16” (1.6mm)

Fig. 2.13

Step 3: Flare pipe ends

Proper flaring is essential to achieve an airtight seal.

1. After removing burrs from cut pipe, seal the ends with

PVC tape to prevent foreign materials from entering the pipe.

2. Sheath the pipe with insulating material as necessary

3. Remove the cut-off valve of outdoor unit and take out the

flare nut from the bag of indoor unit accessories. Fit the flare

nut on the pipe - see Fig 2.11.

4. Make sure it is facing in the right direction, because you

can not remove the nut or change its direction after flaring.

See Fig. 2.12.

5. Remove PVC tape from ends of pipe when ready to

perform flaring work.

6. Clamp flare form on the end of the pipe. The end of the

pipe should extend ~ 1/16” (1.6mm) beyond the edge of the

flare form as shown in Fig. 2.13

7. Place flaring tool onto the form.as shown in Fig. 2.14

8

. Turn the handle of the flaring tool clockwise until the pipe

is fully flared.

9. Remove the flaring tool and flare form, then inspect the

end of the pipe for cracks and even flaring.

Conventional Line Set Installation

Pipe Flaring

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 22

Loading...

Loading...