R-Series Models RP and RH Temposonics

®

Linear-Position Sensors - SSI Output

Product Data Sheet, Part No.: 550989 E (EN) 05/2014

MTS Sensors

7

R-Series Model RP Profile-Style Sensor

Magnet Selections and Sensor Mounting

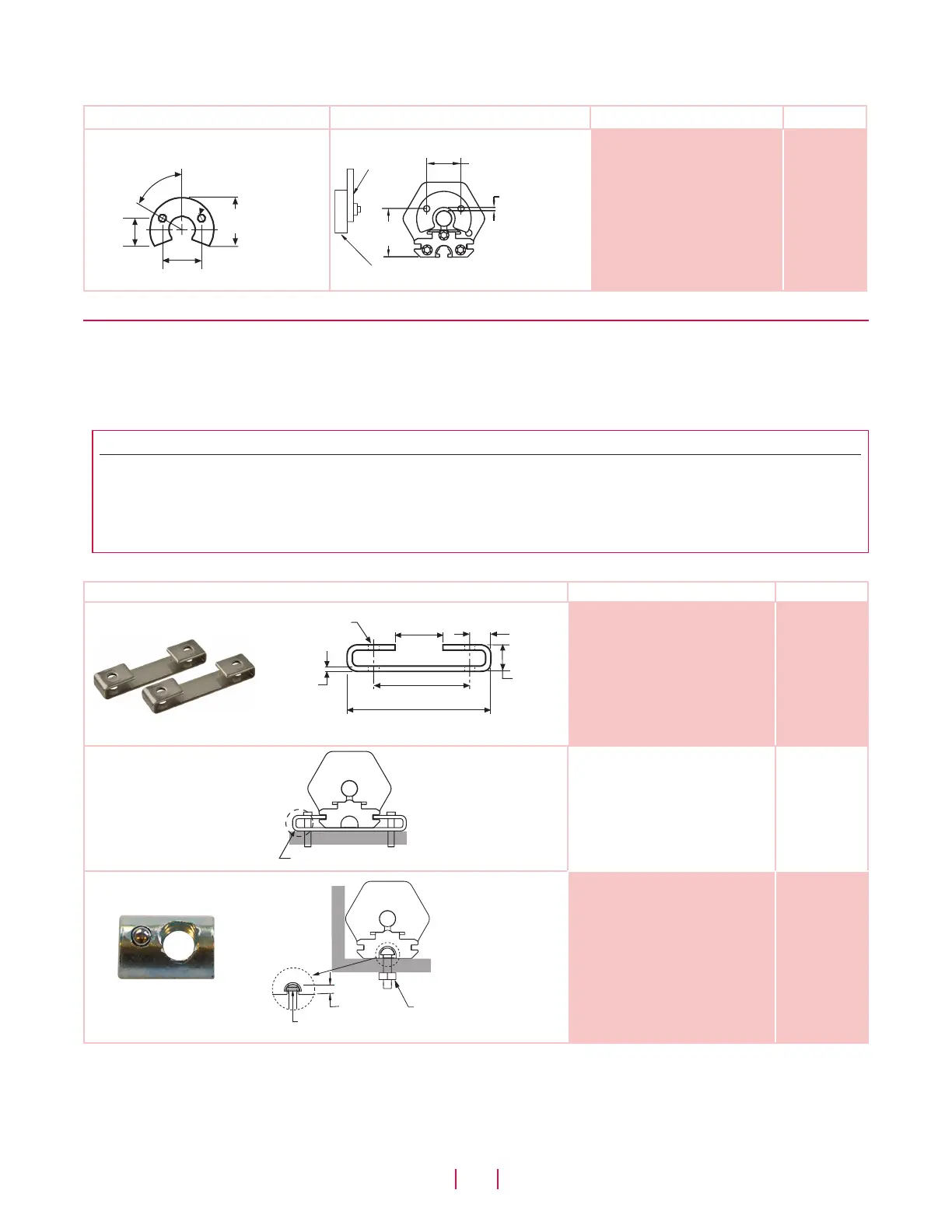

Magnet dimensions Mounted magnet dimensions Description Part number

21 mm

(0.81 in.)

25 mm

(0.97 in.)

14 mm

2 Holes

Each 4.3 mm

(0.17 in.) dia. on

24 mm (0.94 in.) dia.

60°

21 mm

(0.81 in.)

29 mm

(1.14 in.)

Max gap

3 mm ± 1 mm

(0.12 in. ± 0.04 in.)

Non-ferrous mounting support

and screws

Open-ring magnet Style ‘M’

Open-ring magnet,

Style M

I.D.: 13.5 mm (0.53 in.)

O.D.: 33 mm (1.3 in.)

Thickness: 8 mm (0.31 in.)

Operating temperature:

- 40 °C to 100 °C

This magnet may influence the

sensor performance specifica-

tions for some applications.

251416-2

Model RP Sensor mounting

MODEL RP PROFILE-STYLE SENSOR MOUNTING exible installation in any position!

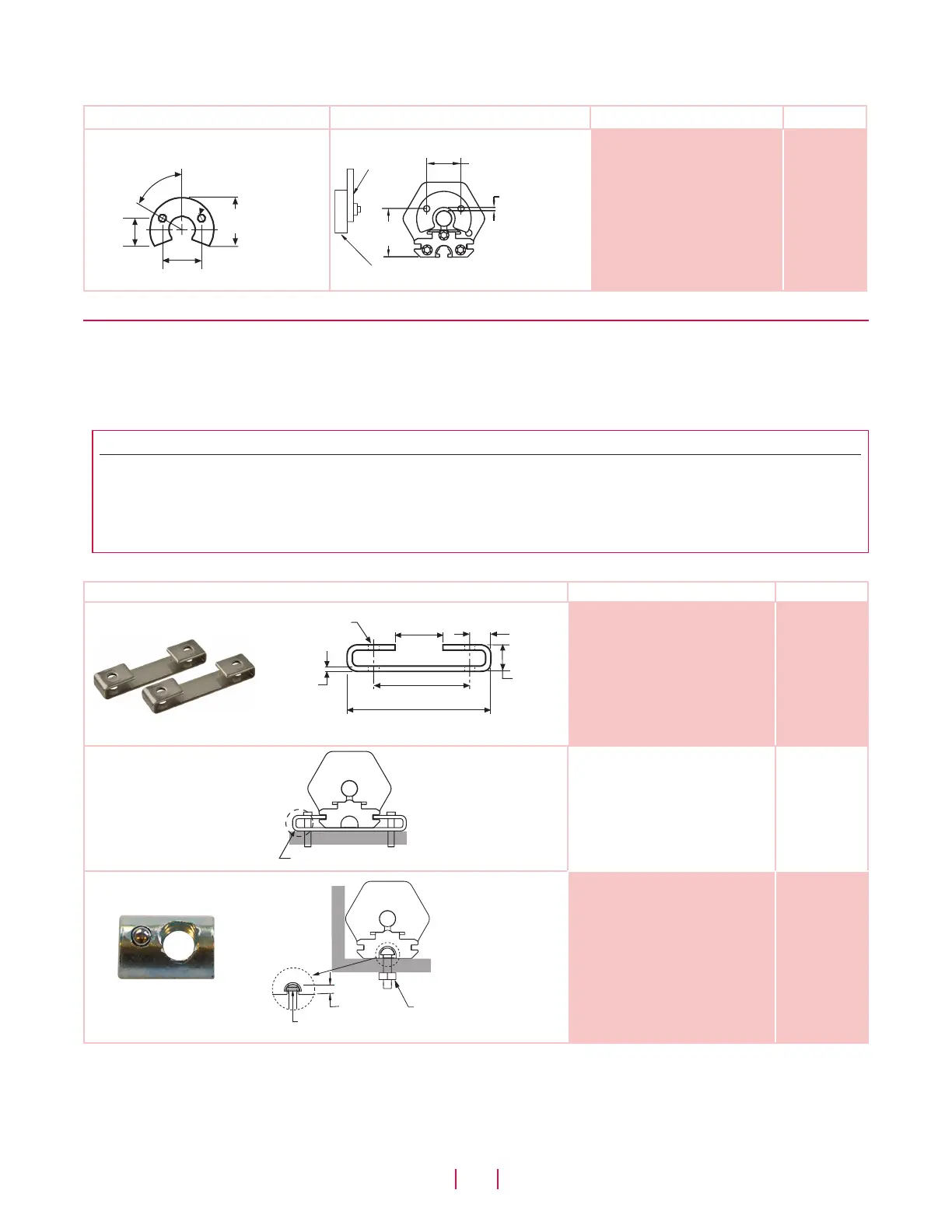

Temposonics Model RP profile-style sensors offer two basic mounting methods; side grooves for use with mounting feet or a bottom groove

that accepts special T-Slot nuts. Both the mounting feet and T-Slot nuts can be positioned along the sensor extrusion to best secure the sensor

for each particular application.

Profile-Style sensor mounting and installation reference Mounting method Part number

4 Holes

5.3 mm

(0.21 in.) dia.

28 mm

(1.1 in.)

9 mm

(0.36 in.)

50 mm

(1.97 in.)

2 mm

(0.08 in.)

68 mm

(2.68 in.)

9 mm

(0.36 in.)

(Width = 14.5 mm (0.57 in.)

Mounting feet, standard (304 SS)

Profile-style sensor mounting for

sensor model RP

400802

10 - 32 Cap screws

Recommended

(Customer supplied)

Mounting foot and screws

Mounting feet and screws

Profile-style sensor foot installation

See

Mounting

Feet

part number:

400802

5 mm (0.20 in.)

T-Slot nut, M5 thread

M5 Threaded

stud and nut

T-Slot nut

Nut for mounting model RP sensor

M5 thread

(optional, ordered separately)

401602

Notes:

1. Model RP sensors include two mounting feet (part no. 400802) for sensors stroke lengths up to 1250 mm (50 in.)

2. One additional mounting foot is included for stroke lengths over 1250 mm (50 in.) and for each additional 500 mm (20 in.),

thereafter.

3. MTS recommends using 10-32 cap screws (customer supplied) at a maximum torque of 44 in. lbs. when fastening mounting feet.

Loading...

Loading...