Loading...

Loading...

Do you have a question about the Mueller E-Star OESE-A51-HFC and is the answer not in the manual?

Details the custom and specialized components of the E-Star OESE condensing units for maximizing energy efficiency.

Guidelines for proper brazing, line set insulation, and system evacuation to 500 microns.

Guidance on verifying compatibility, securing connections, and following NEC regulations for electrical setup.

Details EPA requirements for technicians performing refrigerant installation or service, including certification.

Guidance on triple evacuation to 500 microns and the weigh-in method for startup refrigerant charge.

Step-by-step procedure for accurately weighing in the refrigerant startup charge into the system.

Procedure for fine-tuning the refrigerant charge for optimal system efficiency, including superheat checks.

Explanation of the TEV's role in superheat control and the function of the accumulator heat exchanger.

Guidance on field adjusting the TEV for optimal superheat and critical aspects of its location and sizing.

Procedure for measuring and adjusting evaporator superheat using the TEV.

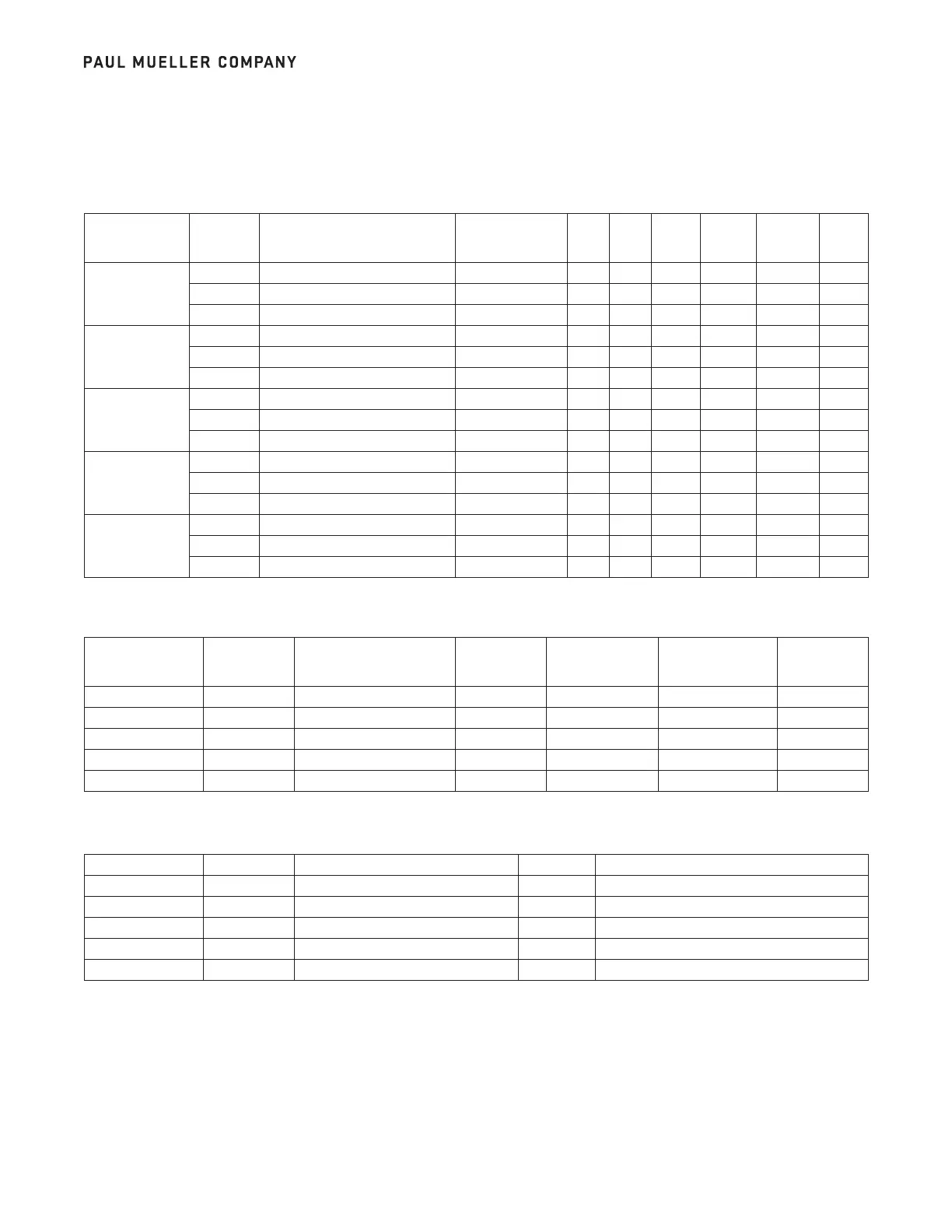

Wiring diagram for 5 HP units with 460/60/3 phase, for control cabinets with 24-volt control output.

Wiring diagram for 5 HP units (pre-Sept 2007) with 460/60/3 phase and 24-volt control output.

Mandates disconnecting power before removing the screen guard to prevent electrical hazards.

Crucial warning about disconnecting all remote power supplies before performing any servicing.

General safety warning that improper handling or service can create health hazards.

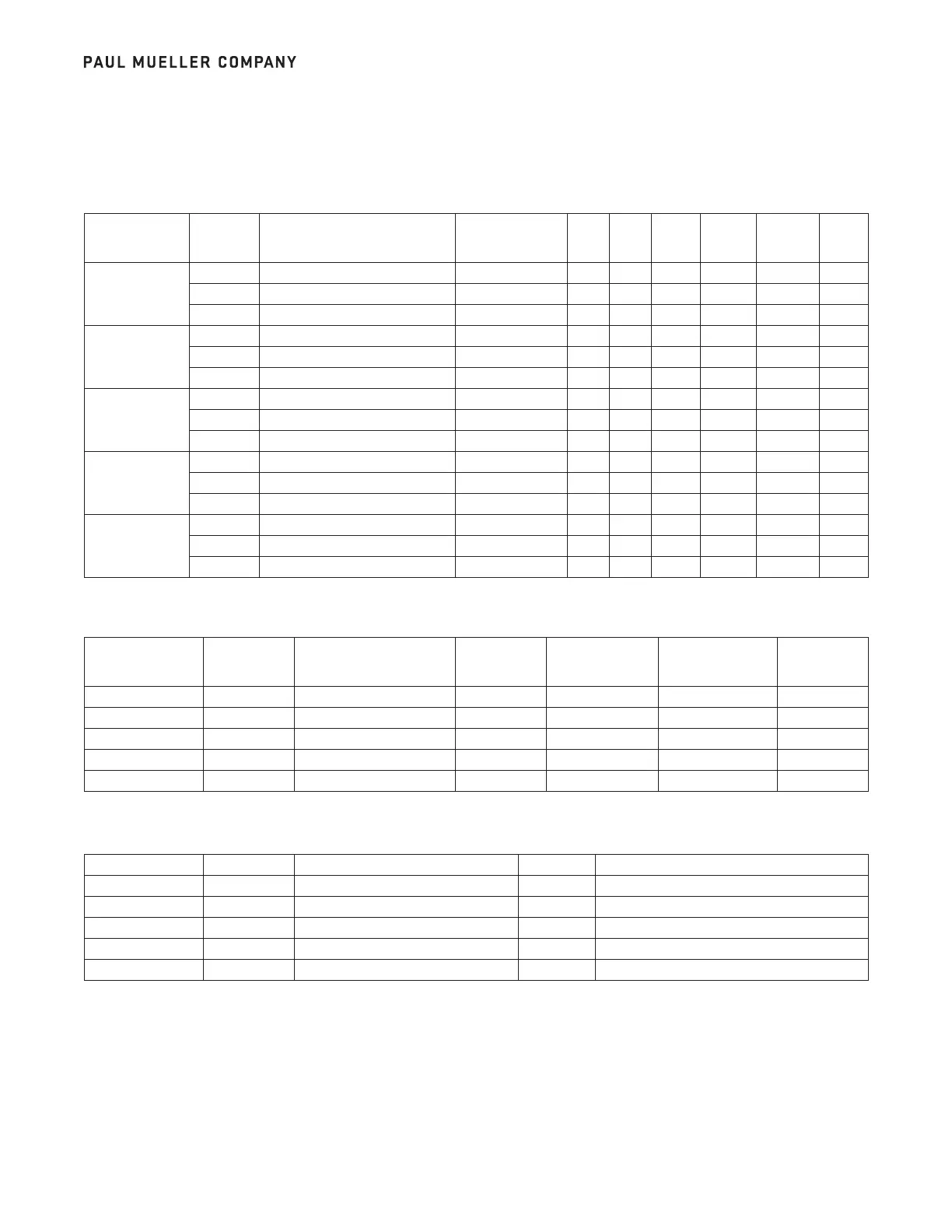

Performance data for ZB26KCE single-phase compressors under various operating conditions.

Performance data for ZB26KCE three-phase compressors under various operating conditions.

Performance data for ZB38KCE single-phase compressors under various operating conditions.

Performance data for ZB38KCE three-phase compressors under various operating conditions.

Performance data for ZB38KCE three-phase compressors at 460V under various operating conditions.