2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C 5.4 Disassembly and Inspection

5-19

e) The low-stage unloader cylinder [60-1] is fastened by

twelve hexagon socket head cap screws [594] to the

low-stage bearing cover [16].

Even when all the hexagon socket head cap screws

are removed, the unloader cylinder will not drop off

as it is securely engaged with the bearing cover. Pull

out the unloader cylinder by holding the flange or rib.

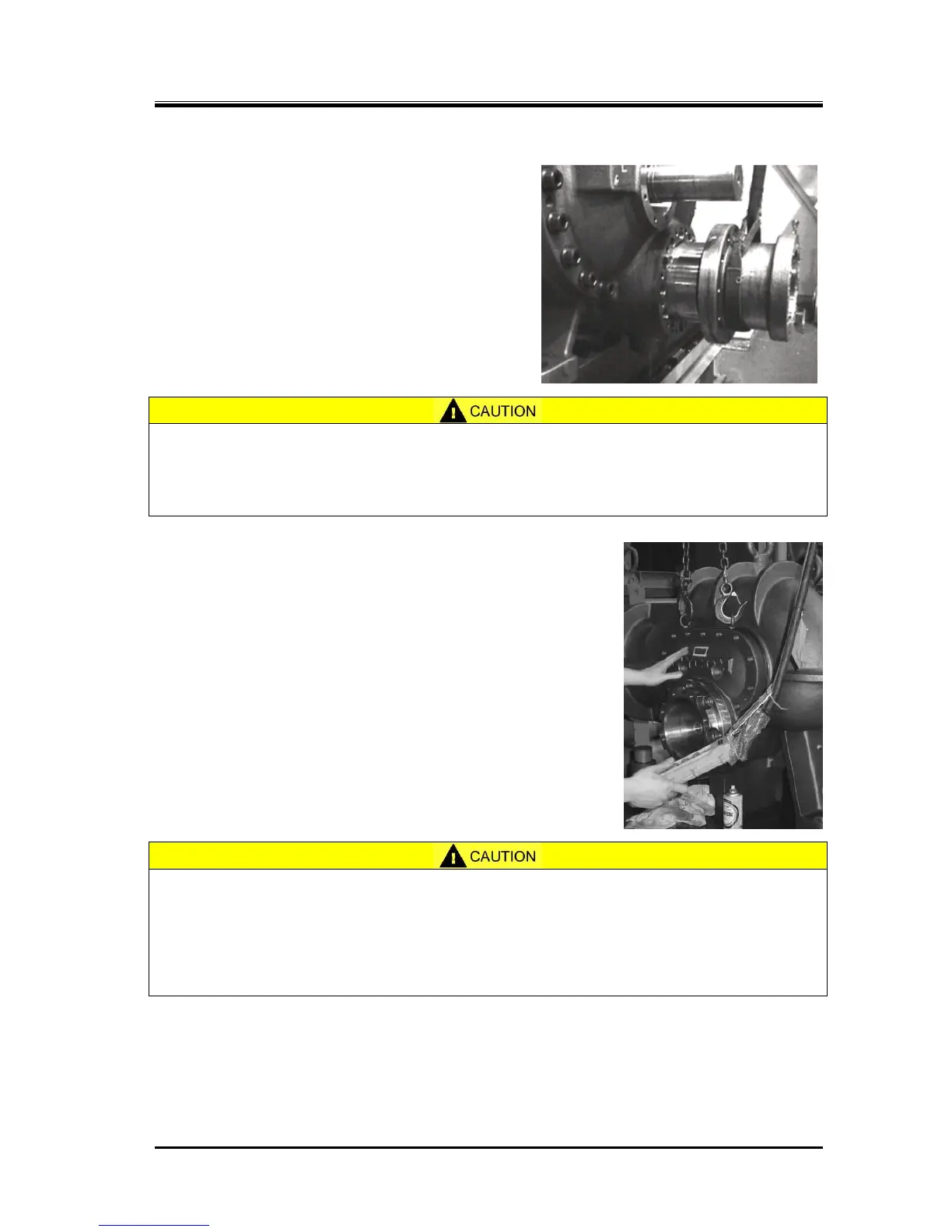

There are some differences in the mass of unloader

cylinder according to the rotor lengths of each model,

however each unloader cylinder weighs around 60

kg. Therefore, wind a sling belt on the cylinder as

shown in the right picture and remove the cylinder

using a crane or like lifting tools.

● In the case of M, L or LL in rotor size, when lifting and pulling out the unloader cylinder

completely by keeping the belt sling position as shown in the above picture, the

cylinder may hit on the push rod due to the mass unbalance and tilt.

When required, change the belt sling position and remove the unloader cylinder.

f) The high-stage unloader cylinder [60-2] is fastened to balance

piston cover by two shortly hexagon socket head cap screws [61]

and fastened to suction cover with balance piston cover by six

long hexagon head cap screws [62].

The high-stage unloader cylinder is to be pulled out similarly to

Step e) for the case of low-stage cylinder.

However, if the cylinder is to be further disassembled, leave the

two bolts [61] fastened. Remove eleven bolts [24] and six bolts

[62] fastening the balance piston cover [22], and remove the

unloader cylinder together with the balance piston cover.

In this, as oil remains in the balance piston and side bearing part,

be careful of the oil that will come out when the balance piston

cover is removed.

If the gasket [23] is sticking and it does not come off, screw in two

M8 eye bolts to the two jucking screw threads on the balance

piston cover to separate the gasket.

● In case of removing the high-stage unloader cylinder together with the balance piston

cover, depending on the model, their mass may weigh over than low-stage unloader

cylinder alone.

When removing the high-stage unloader cylinder with balance piston cover, make sure

to screw toe eyebolts onto the upper part of the balance piston cover to use a crane or

like lifting tools .

5.4.3.2 Inspection

a) Both the O-ring [65-1] [65-2] and cap seal [64-1] [64-2] that are on the periphery of the unloader

piston [64-1] [64-2] must be replaced by new ones.

b) As it is often seen that the inside of the unloader cylinder has flaws or is contaminated by oil residue,

thoroughly clean the area and use fine sandpapers to finish the surface.

Loading...

Loading...