N E T A F I M T E C H L I N E

®

C V D E S I G N G U I D E

N E T A F I M T E C H L I N E

®

C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

LINE FLUSHING VALVES:

Techline CV has a check valve in each dripper designed to hold back a 4

1

/2 foot column of water (2-psi

dripper closing pressure). Therefore, it may not be desirable to use an automatic Line Flushing Valve with

Techline CV, since it could allow water to drain from the dripperline after zone shutdown.

• Line Flushing Valves are used to provide a cleansing action in dripperline each time the zone is turned

on.

• When the zone is turned on, the flush valve begins dumping water into a sump located under it.

• The dumping of water (additional flow) allows the velocity of water inside the dripperline to increase

momentarily helping to clean the inside walls of the tubing.

• This action moves sediments out of the zone and into the sump.

NOTE

FITTINGS:

When laying out Techline CV, you will need to use fittings. If you have chosen a GRID layout, you may

need a transition fitting from the supply piping to the Techline CV. Further, you will use Techline CV

fittings to connect the rows of Techline CV to the headers. If you are using a LITE layout, you will also

use a transition fitting from the supply piping, as well as a fitting at the end or midpoint of the zone so

that a flush point can be installed.

Netafim 17mm barbed insert fittings are designed to speed the installation as well as offer you a broad

range of choices, (see page 38).

The barbed end(s) of all Techline CV fittings is raised and sharp. This allows the fitting to be used with

operating pressures up to 50-psi without clamps. If pressures are expected to exceed 50-psi, a clamp

is recommended. Ensure that the clamp is secured over the raised barb.

Fittings are simply pressed into the tubing. No special tools are required. As with all polyethylene pipe,

do not heat the tubing before inserting the fittings. It is not necessary and it can damage the pipe.

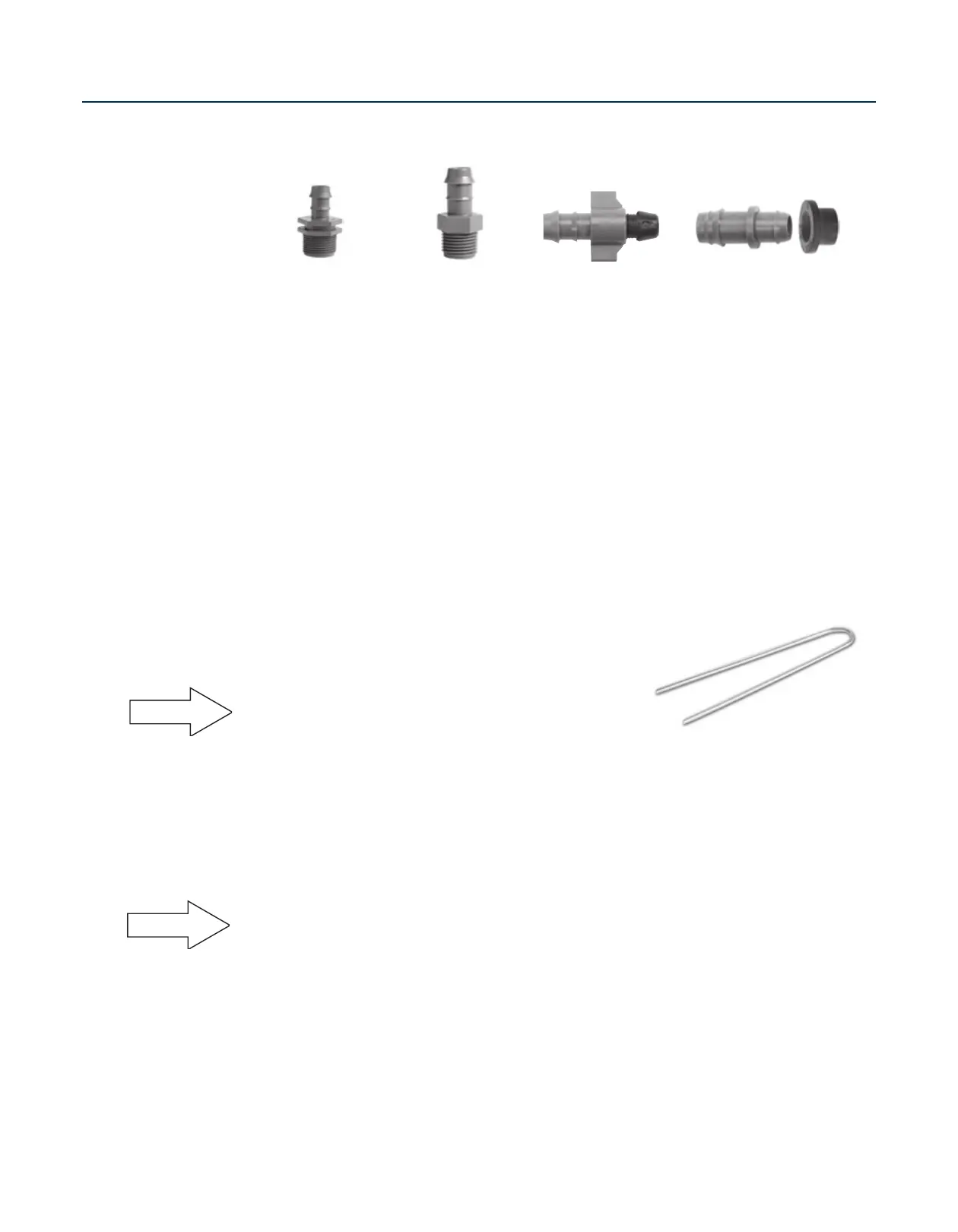

TLS6

NOTE

TLIAPE

STAPLES:

Techline CV staples (TLS6) are used to hold dripperline in place.

While most commonly used when Techline CV is laid on-surface

or under a mulch cover, staples are also valuable when a layout

is being assembled sub-grade before being covered with dirt.

Rule of Thumb: Use a minimum of one staple for every:

• 3 feet of dripperline in sand

• 4 feet of dripperline in loam

• 5 feet of dripperline in clay

Further, use 2 staples “xʼed” over each other with any change-of-direction fittings such as tees, elbows

or crosses.

TLIAPVC

TL075MA

3/4" Male

Adapter

TL050MA

1/2" Male

Adapter

Loading...

Loading...