Do you have a question about the Nice MAESTRO200 Series and is the answer not in the manual?

| Motor Voltage | 24 V DC |

|---|---|

| Protection Level | IP44 |

| Encoder | Yes |

| Maximum Leaf Weight | 400 kg |

| Protection Rating | IP44 |

| Power Supply | 230V AC |

| Safety Features | Obstacle detection |

Describes the product, its purpose, and limitations for residential use.

Lists all necessary devices for a complete automation system.

Ensures gate mechanics and environment are suitable for automation.

Details gate leaf dimensions, weight, and environmental limits for product use.

Explains how to estimate product lifespan based on usage and conditions.

Establishes the positioning of system devices and preparatory site work.

Guides the preparation of all electrical connection cables according to specifications.

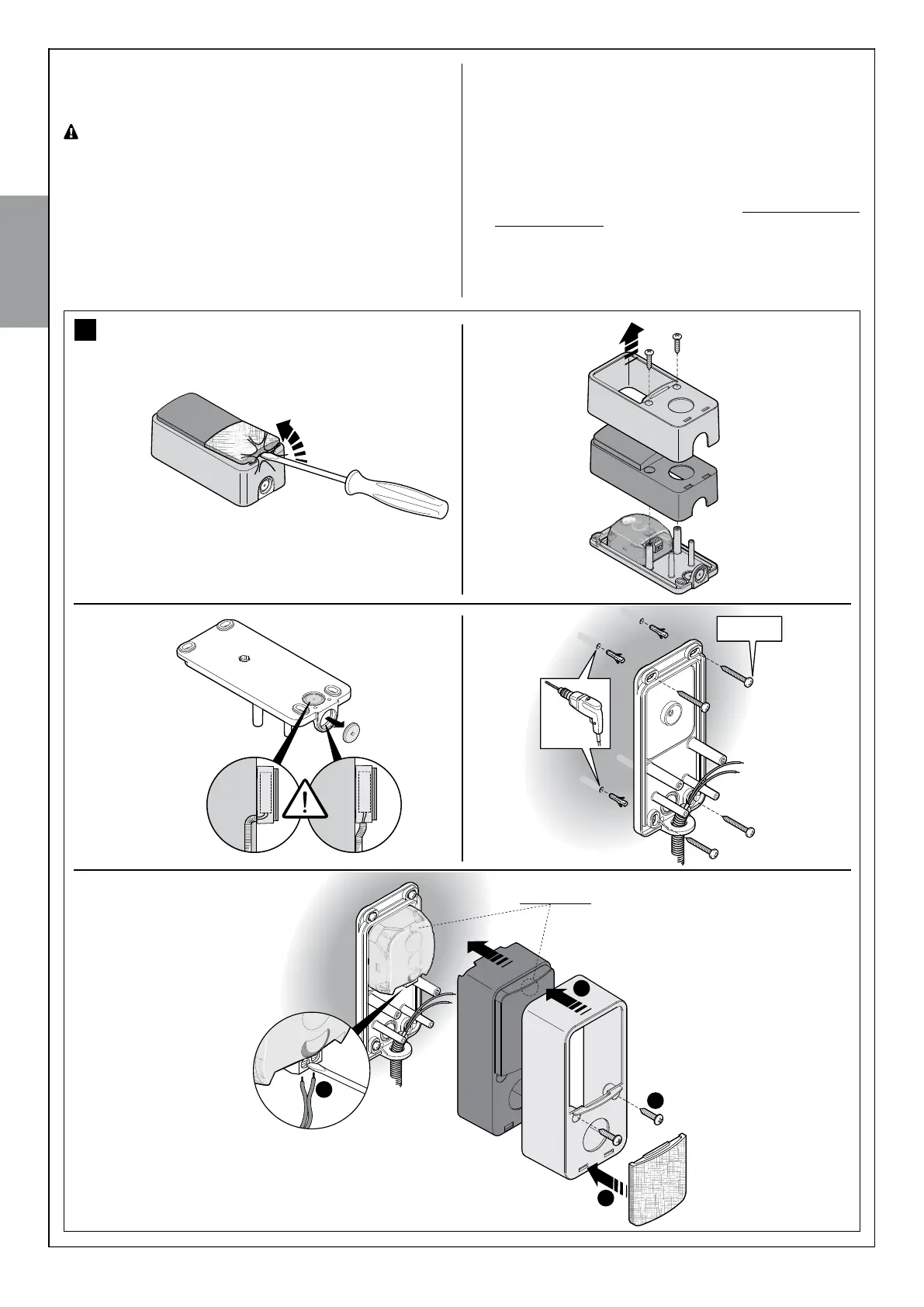

Details the physical mounting and securing of the gearmotor unit.

Explains how to set mechanical limits for gate opening if no external stops are present.

Provides instructions for making the electrical connections to the gearmotor.

Guides the installation and wiring of the PH200 photocell safety devices.

Instructs on installing and connecting the FL200 flashing indicator light.

Explains how to properly connect the automation to the main power supply.

Guides initial electrical checks before proceeding with programming.

Describes the process for the control unit to recognize connected devices.

Details how the system learns the gate's opening and closing limits.

Explains how to verify the functionality of radio transmitters.

Covers selection of leaf speed and operating cycle types for gate automation.

Outlines the essential tests for safety and functionality after installation.

Details the final steps for putting the automation system into operation.

Provides guidelines for the proper disposal of the product.

Explains how to adjust operating parameters using the radio transmitter.

Lists and describes optional accessories for system integration.

Guides on adding or removing compatible devices from the system.

Details the procedure for memorizing radio transmitters with the control unit.

Provides solutions for common malfunctions and errors encountered with the system.

Explains special signals from devices to recognize operating status or malfunctions.