42 - FORM NO. 56043088 / Advenger

™

/ BR 600S, 650S, 700S, 800S

SQUEEGEE SYSTEM

SQUEEGEE SYSTEM LIFT MOTOR OVERVIEW

See Figure 2. The squeegee pickup tool is raised and lowered by a 36V actuator motor assembly mounted horizontally in the center rear of the

chassis underneath the recovery tank. The main control board assembly E1 regulates (manages) the machine’s squeegee tool system input and

output operating functions. See the Know Your Machine section in this manual for a detailed description of vacuum/squeegee operation modes.

OPERATIONAL OVERVIEW OF THE SQUEEGEE LIFT MOTOR REVERSE FUNCTION

During normal machine scrubbing the squeegee operates in the auto mode. To prevent squeegee blade damage and excessive wear the squeegee

tool is automatically lifted from the fl oor any time the machine is operated in reverse. See Figure 1. To get the squeegee tool to lift in reverse the

drive pedal must be moved off its neutral or forward position, which triggers the needed reverse A1 speed control output pin # 16 (Blu/Blk wire).

This (-) battery ground connection delivers the required E1 board input to the J4 connector pin #4 (Blu/Blk wire). This then activates an internal

relay circuit that outputs the correct voltage polarity for the M2 squeegee lift motor to run a specifi ed time (output from J3 connector pins #2 & # 3).

This raises the squeegee off the fl oor to the back up position, which is half of the normal distance observed when in the machine scrub off mode.

Moving the drive pedal back to the neutral/forward position opens the A1 throttle reverse output and the E1 control board loses its battery ground

signal. The J3 connector output reverses the polarity and lowers the tool back onto the fl oor.

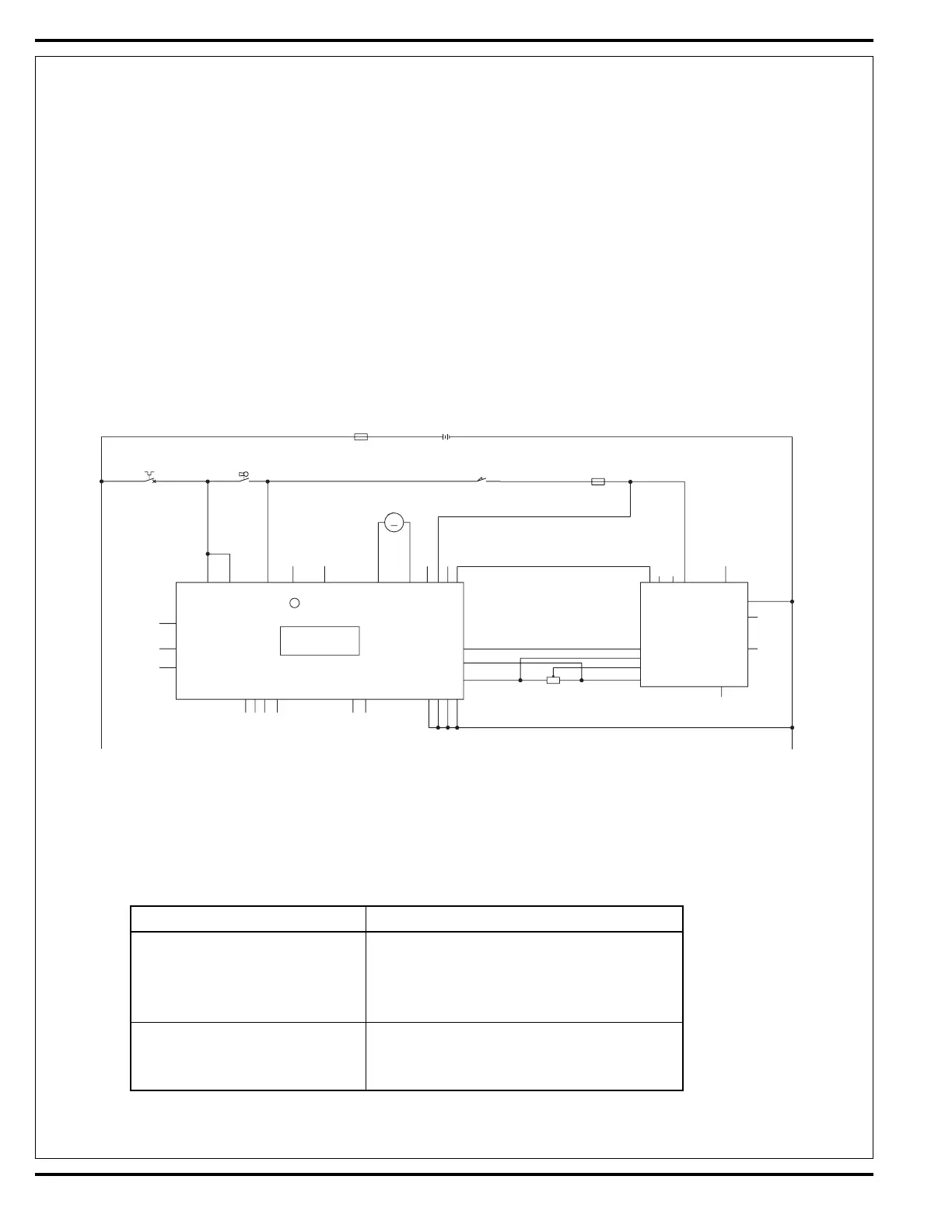

Squeegee Lift Motor Operation

Problem Possible Cause

• Lift Motor runs in both directions • Threads in the moveable lift

but does not raise or lower the motor assembly drive tube are

squeegee tool assembly damaged (stripped)

• Lift cable damaged (stretched or broken)

• Lift motor does not run and the • Lift Motor Electrical system failure*

hourmeter/Status display shows

an error fault code (05, 19, or 20)

*Reference the main control board troubleshooting guide in the Electrical System of this manual for specifi c fault descriptions & service repair

actions.

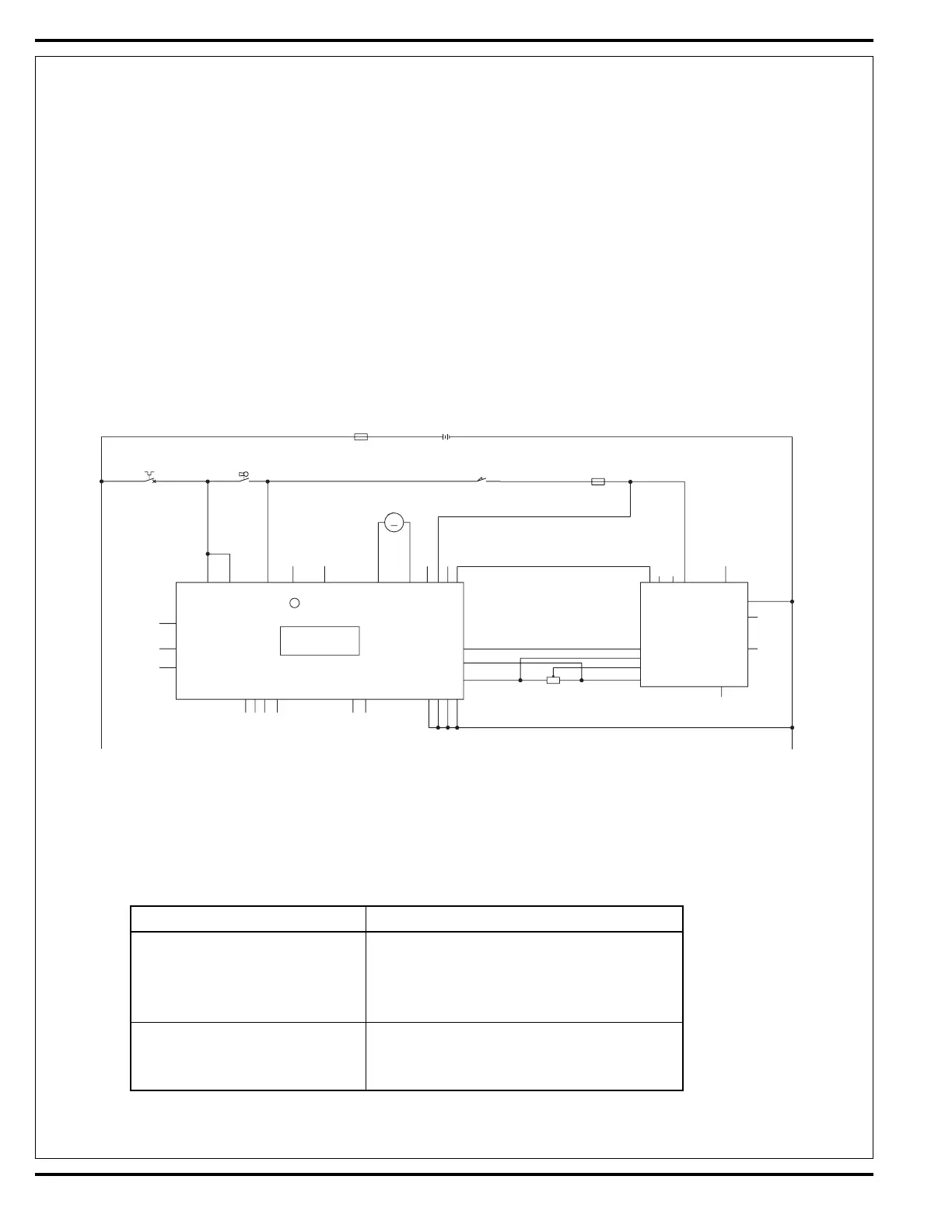

FIGURE 1

* Programming Note: The Squeegee raise in reverse time period is adjustable. See the instruction in the Electrical Special Programming manual section to change

the distance the squeegee will raise in reverse.

TROUBLESHOOTING

M2

SQUEEGEE LIFT

ACTUATOR

M

S2

SW, SEAT

21

BT1

BATTERY, 36 Vdc

F1

S1

SW

SPST KEY

F3

F4

R1

POT. 5K OHM

1

2

3

RED

RED

BLK

RED

BRN/YEL

BRN/YEL

BRN

BLK/YEL

WHT/GRN

GRA

VIO

BLU/BLK

BLK

BLK

BLK

BRN

ORN

ORN ORN

VIO

YEL

YEL

B+ 1

B+ 2

KEY SW.

SEAT SW.

POT. OUT

POT. IN

REV.

PIN 13 -- POT. LO

PIN 3 -- POT. HI

PIN 4 -- POT. WIPER

PIN 16 - REV. ALARM

B+

B-

M2

M1

PIN 8 -- SLOW/FAST

B- 1

B- 2

B- 3

B- 4

A1

SPEED CONTROLLER

INTERFACE

THERMISTOR

E1

CONTROL BOARD

SPEED LIM IT

J4-8

J2-5

J3-5

J3-6

J2-7

J2-6

J2-10

J3-3

J3-2

J4-11

J4-4

J4-9

J4-3

PIN5 -- KSI

J2-9

PIN 18 -- SPEED LIM IT

GND

21

+

2121

+

21

Loading...

Loading...