9

K3MA-J

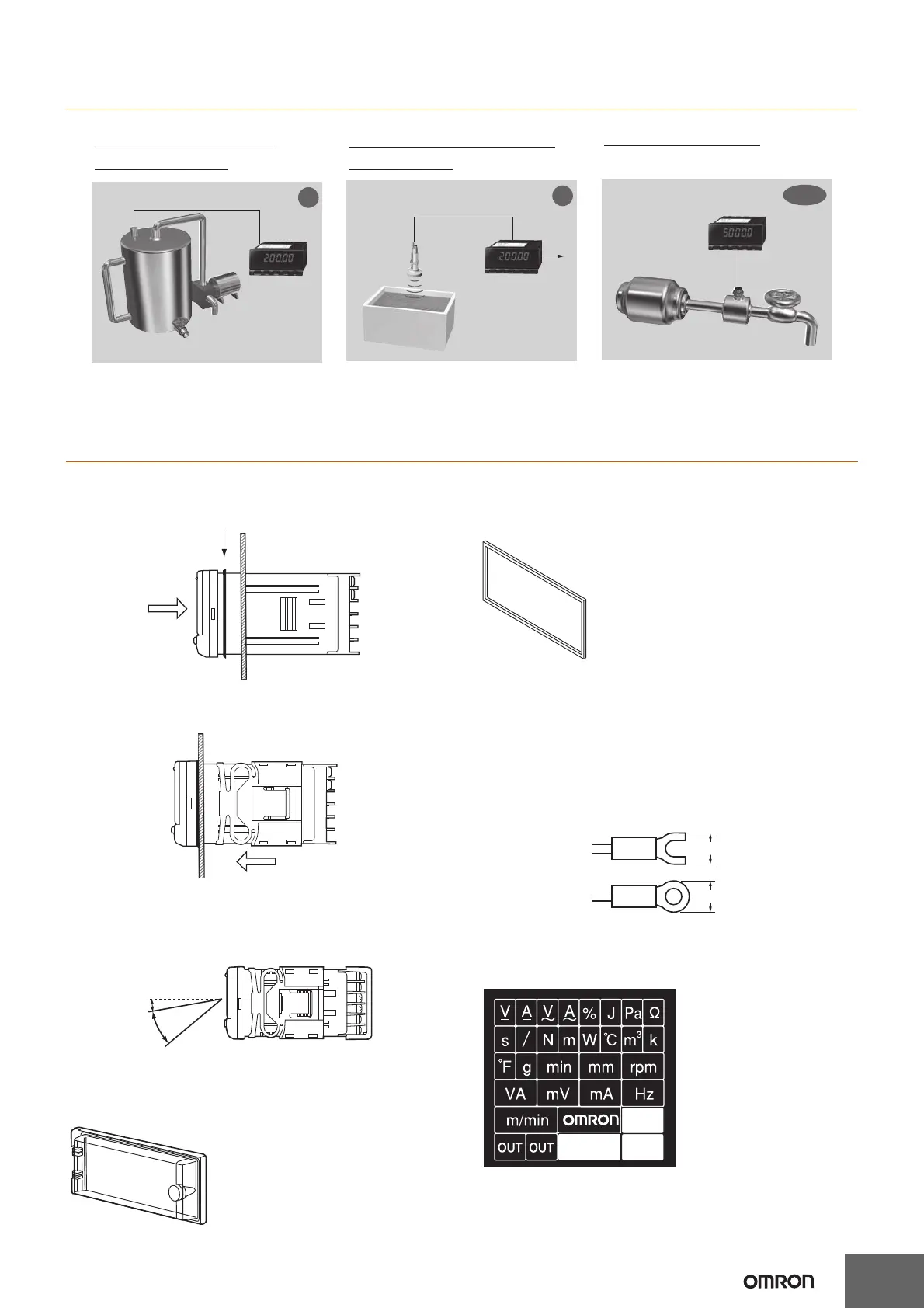

Application Examples

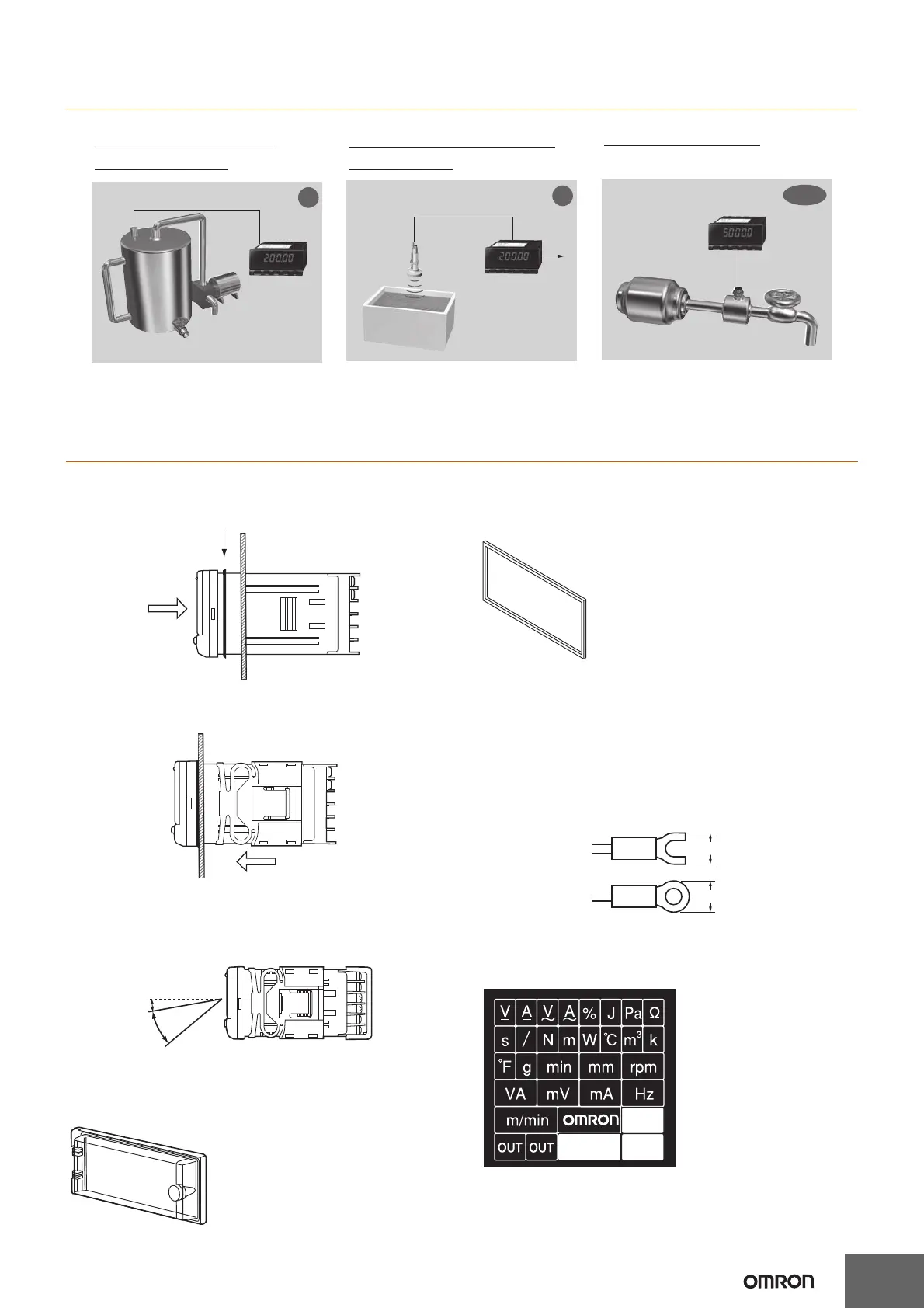

Installation

1. Insert the K3MA-J into the panel cut-out hole.

2. For a waterproof installation, insert the rubber gasket onto the

body of the K3MA-J.

3. Fit the adaptor into the grooves on the left and right sides of the

rear case, then push it until it contacts the panel to secure the

K3MA-J.

■ Angle of View

The K3MA is designed to provide the best visibility at the angles

shown in the following diagram.

■ Watertight Cover

Y92A-49N

■ Rubber Packing

K32-P1

If the rubber packing is lost or damaged, it can

be ordered using the following model number:

K32-P1.

(Depending on the operating environment, dete-

rioration, contraction, or hardening of the rubber

packing may occur and so, in order to ensure

the level of waterproofing specified in NEMA4,

periodic replacement is recommended.)

Note: Rubber packing is provided with the

Controller.

■ Wiring Precautions

• Use crimp terminals.

• Tighten the terminal screws to a torque of approximately 0.5 N⋅m.

• To avoid the influence of noise, route signal lines and power lines

separately.

■ Wiring

• Use the following M3 crimp terminals.

■ Unit Labels (Provided)

• The unit labels are not attached to the K3MA-J. Select the desired

labels from the provided sheet.

Note: For scales and gauges, use the unit labels that are specified by

the relevant laws or regulations.

Flowrate sensorDisplaying/outputting

liquid level

Monitoring interior

tank pressure

E8AA Pressure Sensor

4 to 20 mA

K3MA-J

Tank

Discharge valve

Pump

E4PA Ultra-

sonic Dis-

placement

Sensor

4 to 20 mA

or 0 to 10 V

K3MA-J

Pump

K3MA-J

4 to 20 mA

Flowrate Sensor

m/min

mm

Pa

• Monitoring gas pressure

• Inspection instruments in food or phar-

maceutical plants

• Monitoring liquid level in cleaning tanks • Monitoring send-out flowrate

• Water processing devices, etc.• Water tanks, devices using chemicals,

etc.

10°

30°

5.8 mm max.

5.8 mm max.

Loading...

Loading...