Ventilation

and

Acoustics

VENTILATION

The most important factors

of

ventilation for an

RV

air-

cooled generator set are sufficient incoming air (for

combustion and cooling) and adequate exhausting of

heated air.

All

Onan generator sets for recreational veh-

icles

use Vacu-Flo@ cooling.

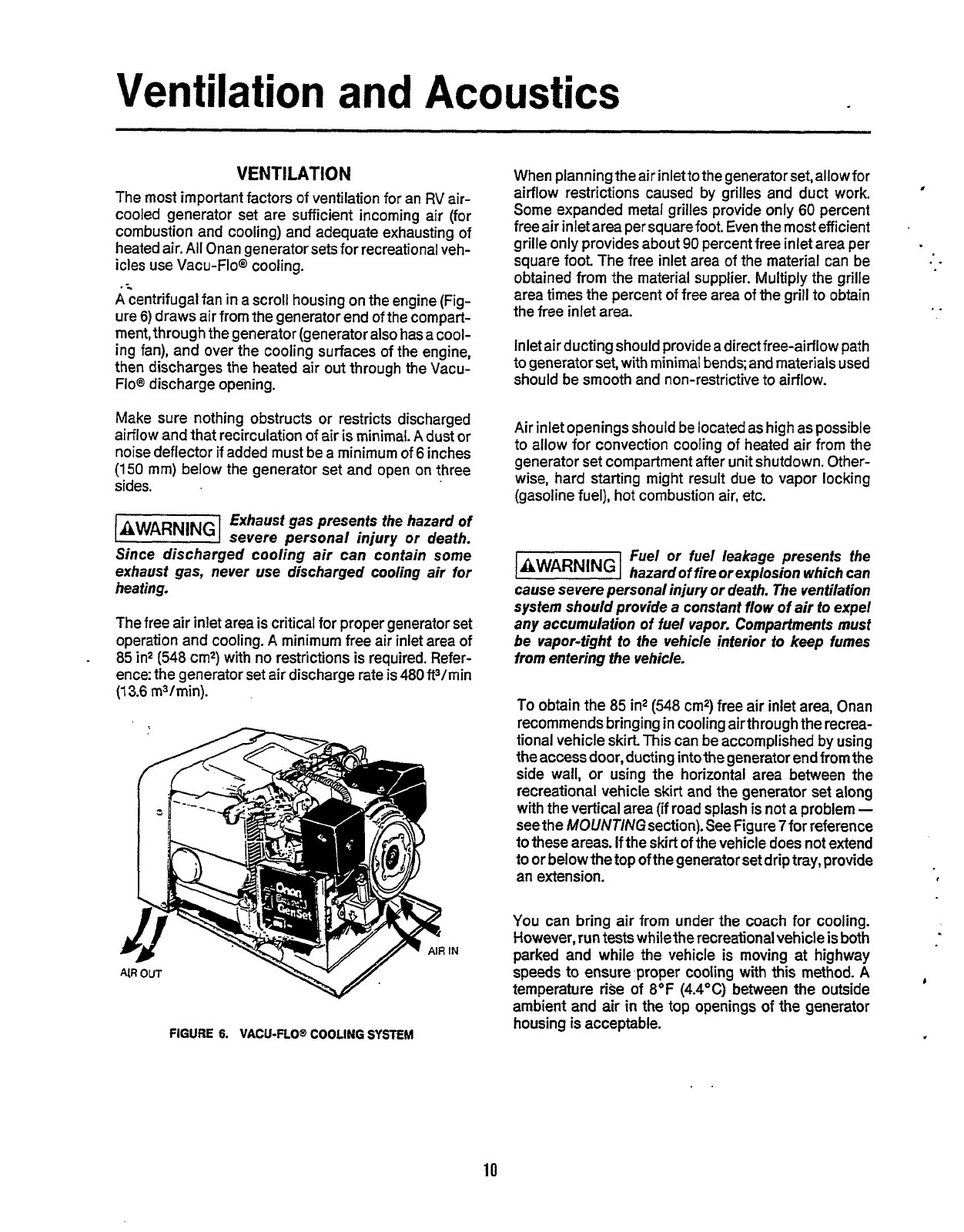

Acentrifugal fan in a scroll housing on the engine (Fig-

ure

6)

draws air from the generator end of the compart-

ment, through the generator (generator also has a cool-

ing fan), and over the cooling surfaces of the engine,

then discharges the heated air out through the Vacu-

Floe

discharge opening.

Make sure nothing obstructs or restricts discharged

airflow and that recirculation

of

air is minimal.

A

dust or

noise deflector

if

added must be a minimum of

6

inches

(150

mm) below the generator set and open on three

sides.

Exhaust gas presenfs the hazard

of

(BWARNINGI

severe personal injury

or

death.

Since discharged cooling air can contain some

exhaust gas, never use discharged cooling air for

heating.

The free air inlet area is critical

for

proper generator set

operation and cooling.

A

minimum free air inlet area of

85

in2

(548

cm2) with no restrictions is required. Refer-

ence: the generator set air discharge rate is

480

ft3/min

(1

3.6

m3/min).

-

FIGURE

6.

VACU-FLO@

COOLING

SYSTEM

When planning the air inletto thegenerator set,allowfor

airflow restrictions caused by grilles and duct work.

Some expanded metal grilles provide only

60

percent

free air inlet area per square foot. Even the most efficient

grille only provides about

90

percent free inlet area per

square foot The free inlet area of the material can be

obtained from the material supplier. Multiply the grille

area times the percent

of

free area

of

the grill to obtain

the free inlet area.

Inlet air ducting should provide a direct free-airflow path

to generator set, with minimal bends; and materials used

should be smooth and non-restrictive to airflow.

Air inlet openingsshould be located as high as possible

to allow for convection cooling of heated air from the

generator set compartment after unit shutdown. Other-

wise, hard starting might result due to vapor locking

(gasoline fuel), hot combustion air, etc.

Fuel or fuel leakage presents the

IBWAR”G1

hazardof fire

or

explosion which can

cause severe personal injury or death. The ventilation

system should provide a constant flow of air

to

expel

any accumulation of fuel vapor. Compartments must

be

vapor-tight to the vehicle interior

to

keep fumes

from entering the vehicle.

To

obtain the

85

in2

(548

cm2) free air inlet area, Onan

recommends bringing in cooling airthtough the recrea-

tional vehicle skirt. This can be accomplished by using

the access door, ducting intothe generator end from the

side wall, or using the horizontal area between the

recreational vehicle skirt and the generator set along

with the vertical area (if road splash

is

not a problem

-

see the MOUNTINGsection).See Figure 7for reference

to these areas. If the skirt of the vehicle does not extend

to or below the

top

of the generator set drip tray, provide

an extension.

You

can bring air from under the coach for cooling.

However, run tests while the recreational vehicle

is

both

parked and while the vehicle is moving at highway

speeds to ensure proper cooling with this method.

A

temperature rise of

8°F

(4.4OC)

between the outside

ambient and

air

in

the top openings of the generator

housing

is

acceptable.

I

..

..

,

b

..

10

Redistribution or publication of this document,

by any means, is strictly prohibited.