3-2

weld nuts to facilitate installing screws. The

front two holes can be secured with 3/8-16

screws, lock-washers, and nuts. The front

holes are square to allow the use of 3/8-16

cage nuts, if desired. See the appropriate fig-

ure in Section

9. Outline Drawings.

CAUTION

Road vibrations can cause

component damage to the genset if the unit

mounting plate is not fastened securely to

the vehicle compartment. Use screws of

sufficient length to allow a minimum of 1

1

/

2

threads to extend through the nut for maxi-

mum holding power.

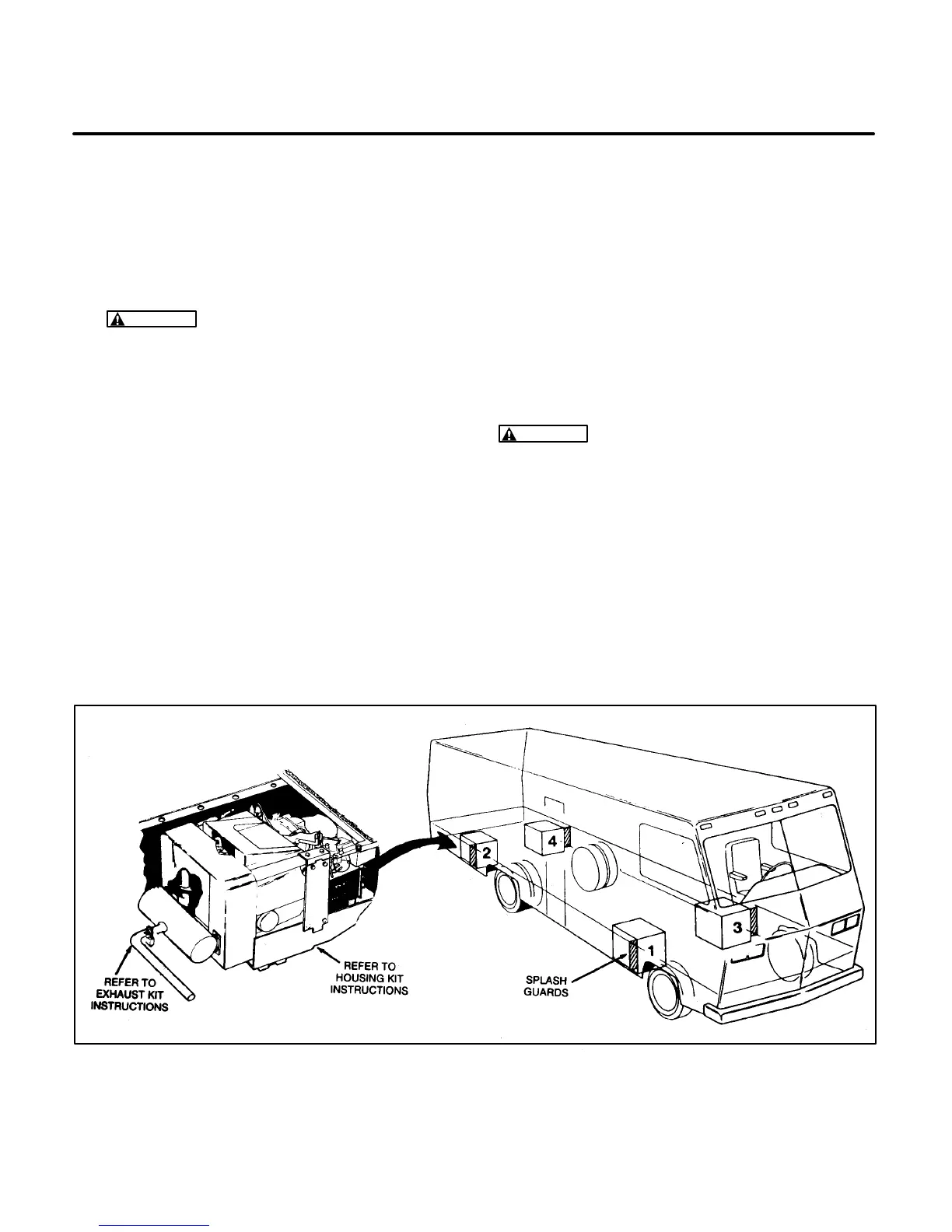

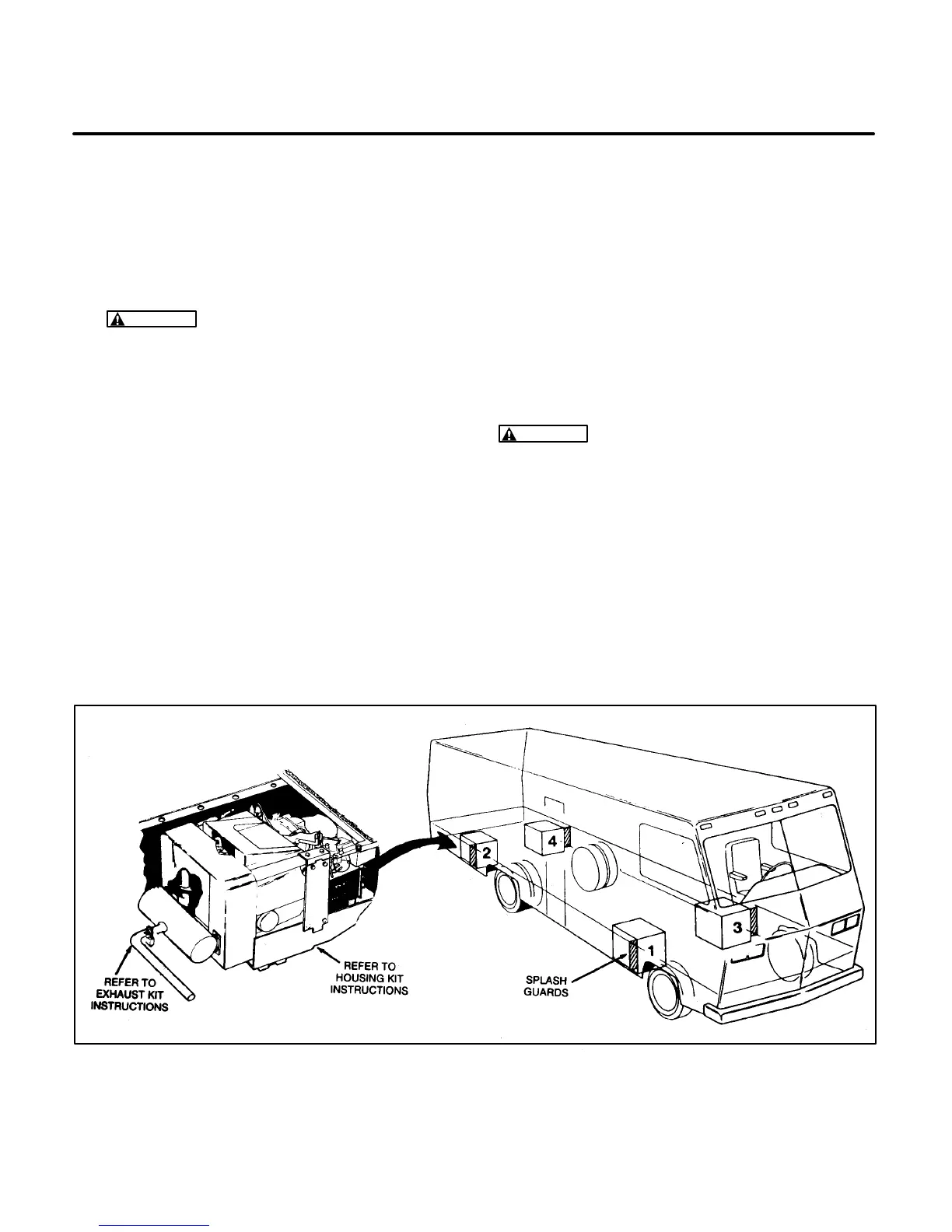

UNDER-FLOOR MOUNT

In an under-floor mount installation, the genset is

mounted in a housing below the floor and outside

the vehicle coach. This housing assembly should

be as supplied or reviewed by Onan, and must be

installed in accordance with the Installation Codes

and Safety Recommendations list in the

Introduc-

tion.

Review the following text for general applica-

tion information, and review the proper housing/ex-

haust kit instructions for further specifics regarding

under-floor mount instructions.

The vehicle construction must be able to support

the weight of the genset (see

General Specifica-

tions).

It is the vehicle manufacturer’s and the in-

staller’s responsibility to provide a structurally

sound support frame, by using tubing, angle brack-

ets, or steel reinforced plywood or other composi-

tion board. Reinforcement of plywood or other com-

position board can be accomplished with 3-inch (76

mm) or larger washers or a full metal plate.

WARNING

Design the genset support struc-

ture carefully to prevent the genset from falling

from the vehicle and possibly causing a serious

road accident.

General

Genset Location.

When choosing a location for

mounting the under-floor mount genset, consider

the following not only for mounting, but for protec-

tion of the genset, as well. Figure 3-2 shows the

most common mounting areas of an RV genset in a

recreational vehicle.

FIGURE 3-2. COMMON UNDER-FLOOR MOUNTING AREAS OF GENSET

Loading...

Loading...