4. Ventilation and Acoustics

4-1

WARNING

EXHAUST GASES ARE DEADLY!

Never sleep in the vehicle with the genset run-

ning unless the vehicle is equipped with an op-

erating carbon monoxide detector with an audi-

ble alarm.

WARNING

Provide an adequate exhaust sys-

tem to properly expel discharged gases. In-

spect exhaust system daily for leaks per the

maintenance schedule. Check that exhaust

manifolds are secure and not warped. Do not

use exhaust gases to heat a compartment.

WARNING

Be sure the unit is well ventilated.

VENTILATION

The most important factors of ventilation for an RV

air-cooled genset are sufficient incoming air (for

combustion and cooling) and adequate exhausting

of heated air. The BGE/NHE genset uses Vacu-

Flo cooling.

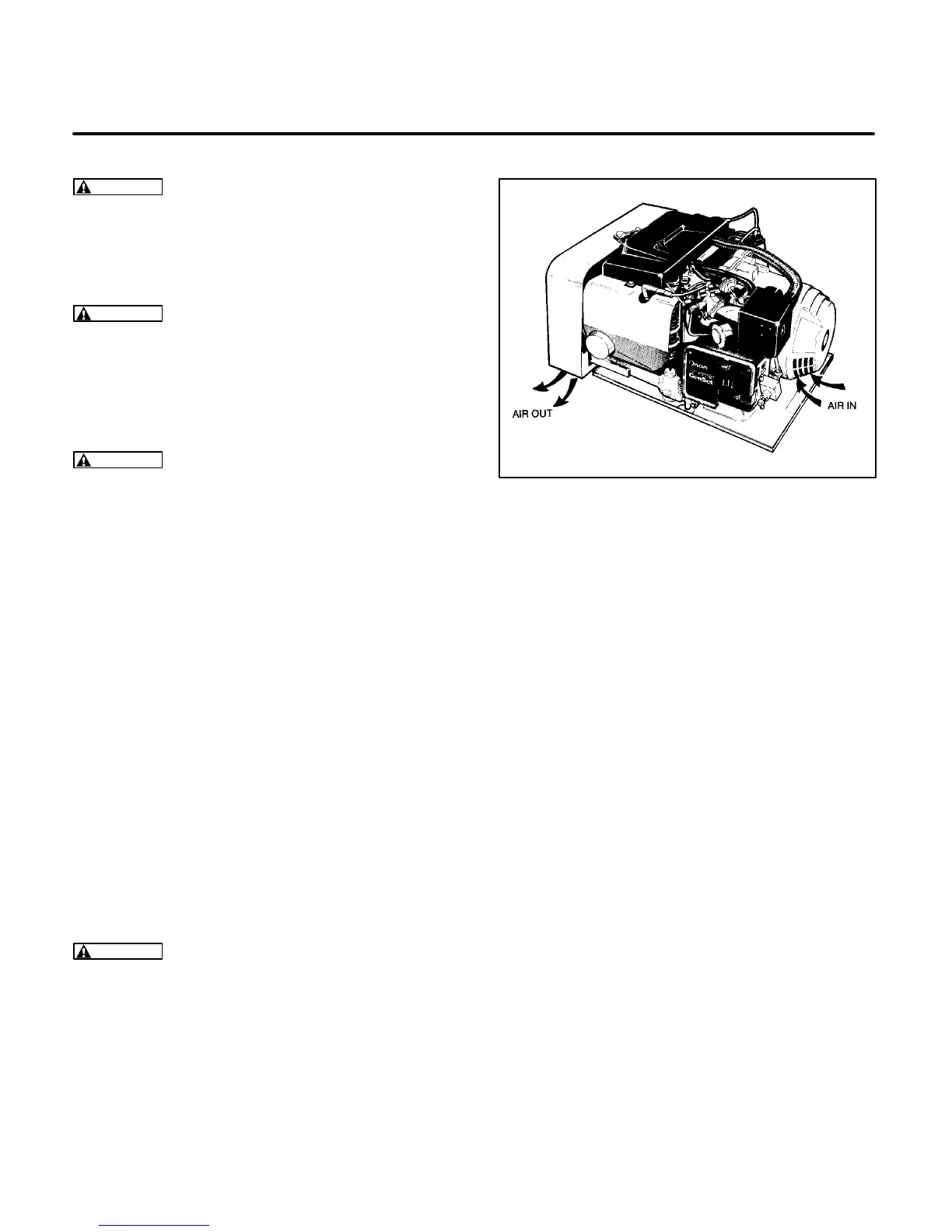

A centrifugal fan in a scroll housing on the engine

(Figure 4-1) draws air from the generator end of the

compartment, through the generator (the generator

also has a cooling fan), and over the cooling sur-

faces of the engine. Then, it discharges the heated

air out through the Vacu-Flo discharge opening.

Make sure nothing obstructs or restricts discharged

airflow and that recirculation of air is minimal. A dust

or noise deflector, if added, must be a minimum of 3

inches (76 mm) below the genset and open on three

sides.

WARNING

Exhaust gas presents the hazard of

severe personal injury or death. Because dis-

charged cool air can contain some exhaust gas,

never use discharged cooling air for heating.

FIGURE 4-1. VACU-FLO

COOLING SYSTEM

The air inlet area is critical for proper genset opera-

tion and cooling. A minimum air inlet area of 85 in

2

(548 cm

2

) with no restrictions is required. Refer-

ence: the genset air discharge rate is 480 ft

3

/min

(13.6 m

3

/min).

When planning the air inlet to the genset, allow for

airflow restrictions caused by grilles and duct work.

Some expanded metal grilles provide only 60 per-

cent free air inlet area per square foot. Even the

most efficient grille only provides about 90 percent

free inlet area per square foot. The free air inlet area

of the material can be obtained from the material

supplier. Multiply the grille area times the percent of

free area of the grill to obtain the free inlet area.

Inlet air ducting should provide a direct, free, air-

flow path to the genset, with minimal bends. Materi-

als used should be smooth and non-restrictive to

airflow.

Air inlet openings should be located as high as pos-

sible to allow for convection cooling of heated air

from the genset compartment after unit shutdown.

Otherwise, hard starting might result due to vapor

locking (gasoline fuel), hot combustion air,

etc.

Loading...

Loading...