6-3

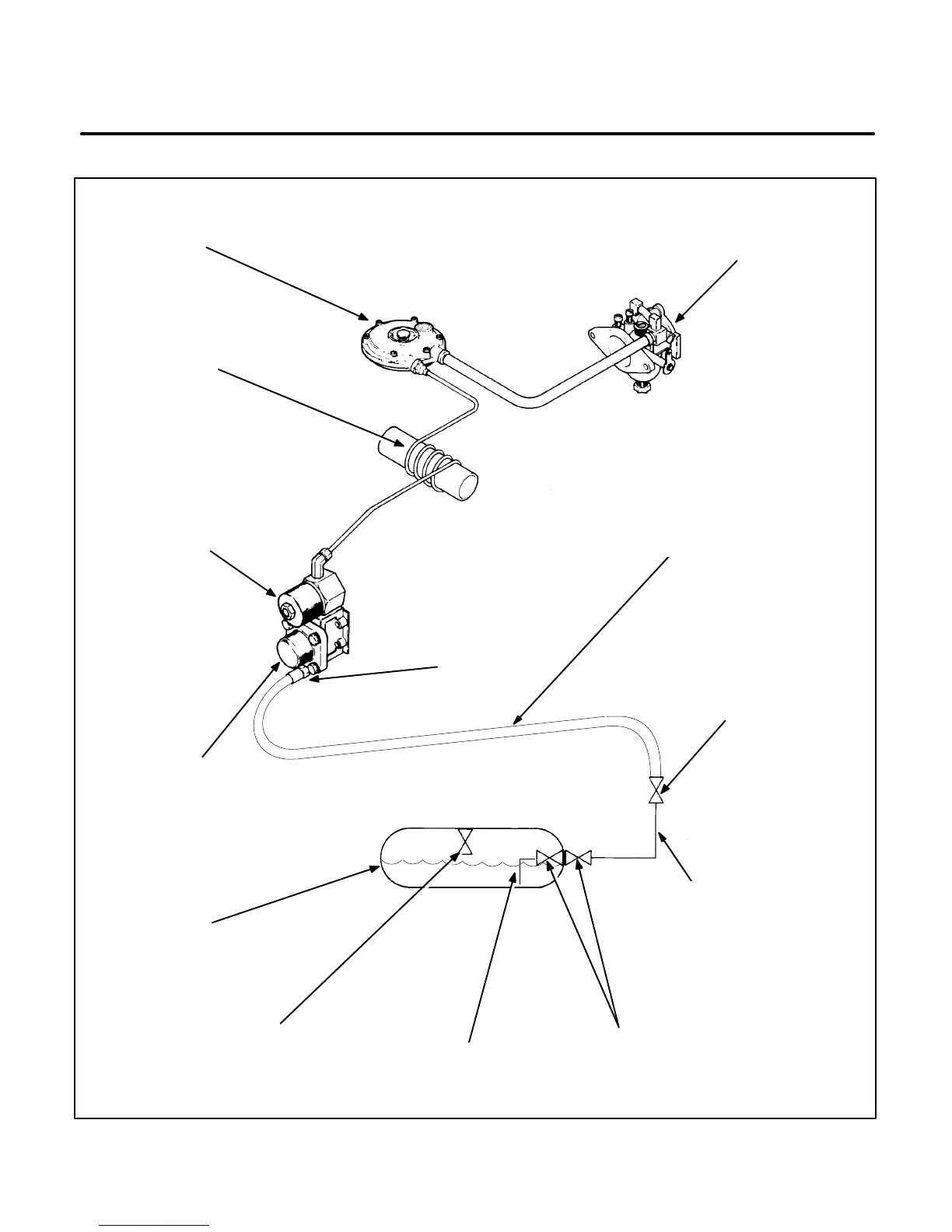

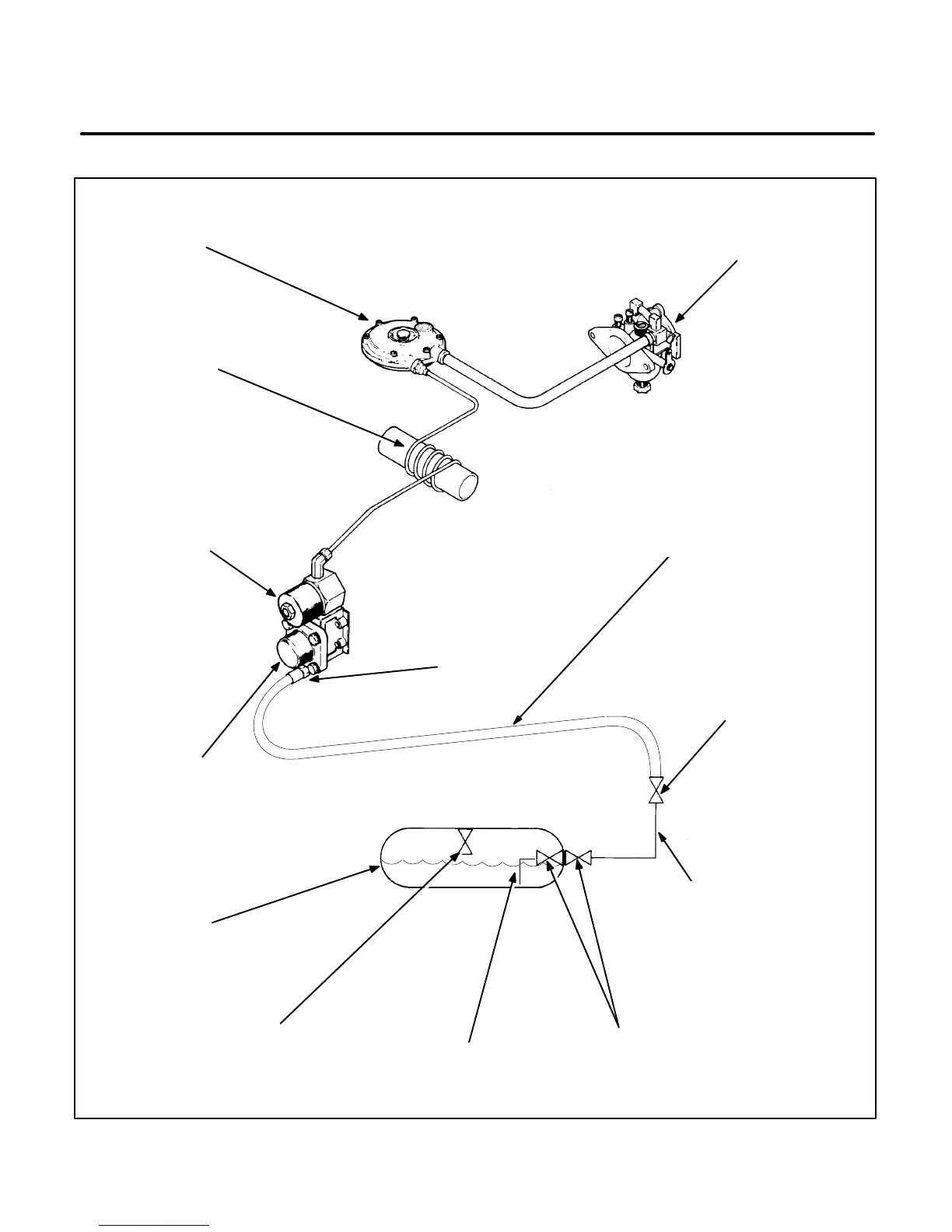

TWO-STAGE, DEMAND-TYPE

PRESSURE REGULATOR

THE LPG IS VAPORIZED BY

EXHAUST MANIFOLD HEAT.

AN APPROVED

HYDROSTATIC RELIEF

VALVE OF APPROPRIATE

RATING TO PROTECT THE

GAS LINE. WHEN VALVES

ON BOTH ENDS ARE

CLOSED

THE FUEL FILTER HAS A

STRAINER ELEMENT

ACCESSIBLE FOR

CLEANING AND A MAGNET

FOR TRAPPING IRON

PARTICLES.

THE FUEL SOLENOID

SHUTOFF VALVE ALLOWS

BACKFLOW TO RELIEVE

PRESSURE WHILE THE

VAPORIZER COOLS

FOLLOWING SHUTDOWN.

VENTURI-TYPE CARBURETOR

WITH MAIN AND IDLE

MIXTURE ADJUSTMENTS

FUEL SUPPLY

CONNECTION

AT THE

GENSET

(1/4 INCH NPTF)

USE AN APPROVED,

NON-CONDUCTING FLEXIBLE

FUEL HOSE MARKED 350 PSI

WORKING PRESSURE AND

LP-GAS OR PROPANE TO

CONNECT THE GENSET TO THE

GAS SUPPLY LINE.

APPROVED GAS

LINES AND FITTINGS

SUITABLE FOR A

WORKING

PRESSURE OF AT

LEAST 250 PSI (1.7

MPa)

AN APPROVED PRESSURE RELIEF VALVE

OF APPROPRIATE RATING

COMMUNICATING WITH THE VAPOR SPACE

INSIDE THE TANK

AN APPROVED DOT OR

ASME LPG SUPPLY TANK

DIP

TUBE

APPROVED MANUAL SHUTOFF AND

EXCESS FLOW VALVES RATED FOR A

WORKING PRESSURE OF AT LEAST 250 PSI

(1.7MPa)

FIGURE 6-2. FLOW DIAGRAM OF LPG FUEL SYSTEM

Loading...

Loading...