BRACKET

FIGURE

33.

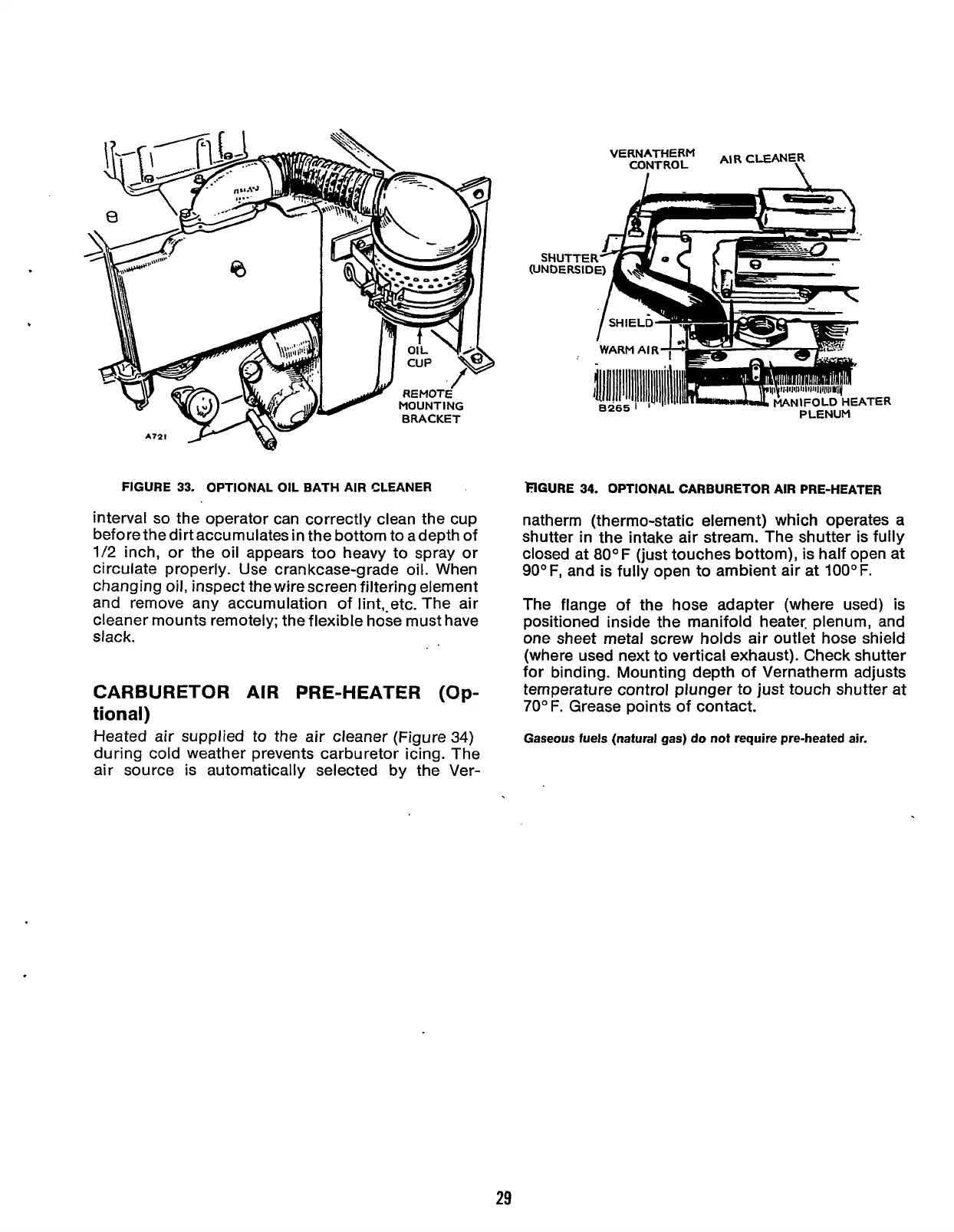

OPTIONAL OIL BATH AIR CLEANER

interval

so

the operator can correctly clean the cup

before the dirt accumulates in the bottom to adepth of

1/2

inch,

or

the oil appears too heavy to spray

or

circulate properly. Use crankcase-grade oil. When

changing oil, inspect the wirescreen filtering element

and remove any accumulation

of

lint,.etc. The air

cleaner mounts remotely; the flexible hose must have

slack.

CARBURETOR

AIR

PRE-HEATER

(Op-

tional)

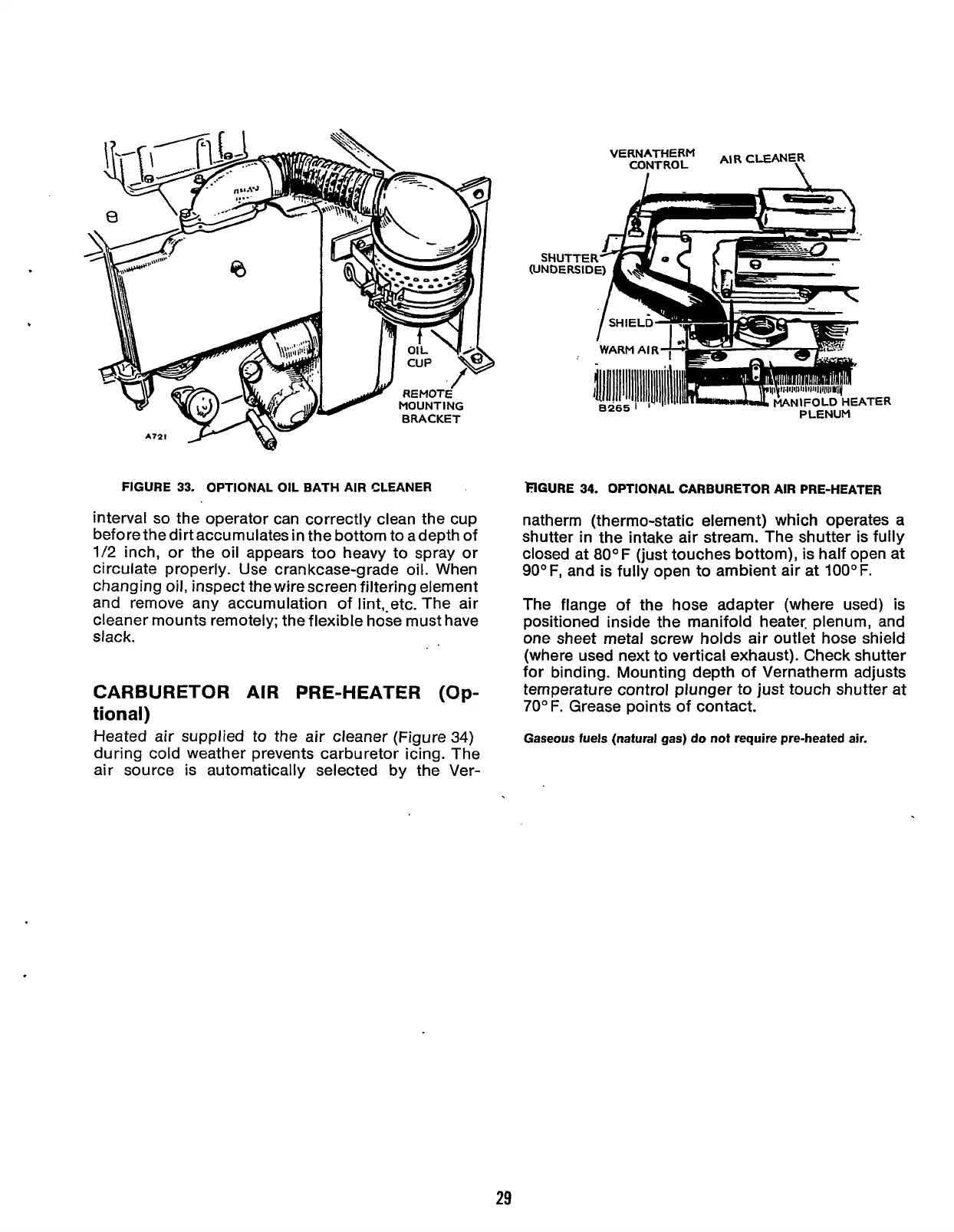

Heated air supplied to the air cleaner (Figure

34)

during cold weather prevents carburetor icing. The

air source is automatically selected by the Ver-

VERNATHERM

CONT'ROL

I

AIR

CLEANER

\

SHUTT

(UNDERS

PLENUM

TER

'FIGURE

34.

OPTIONAL CARBURETOR AIR PRE-HEATER

natherm (thermo-static element) which operates

a

shutter in the intake air stream. The shutter is fully

closed at

80"

F

(just touches bottom), is half open at

90°F,

and

is

fully open to ambient air at

100°F.

The flange of the hose adapter (where used) is

positioned inside the manifold heater. plenum, and

one sheet metal screw holds air outlet hose shield

(where used next to vertical exhaust). Check shutter

for binding. Mounting depth of Vernatherm adjusts

temperature control plunger to just touch shutter at

70"

F.

Grease points of contact.

Gaseous fuels (natural gas)

do

not

require pre-heated air.

29

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...