ASSEMBLY

TORQUES

AND

SPECIAL TOOLS

ASSEMBLY

TORQUES

The assembly torques given here will assure proper

tightness without danger of stripping threads. If a

torque wrench is not available, be careful not to strip

threads. Use reasonable force only and a wrench of

normal length.

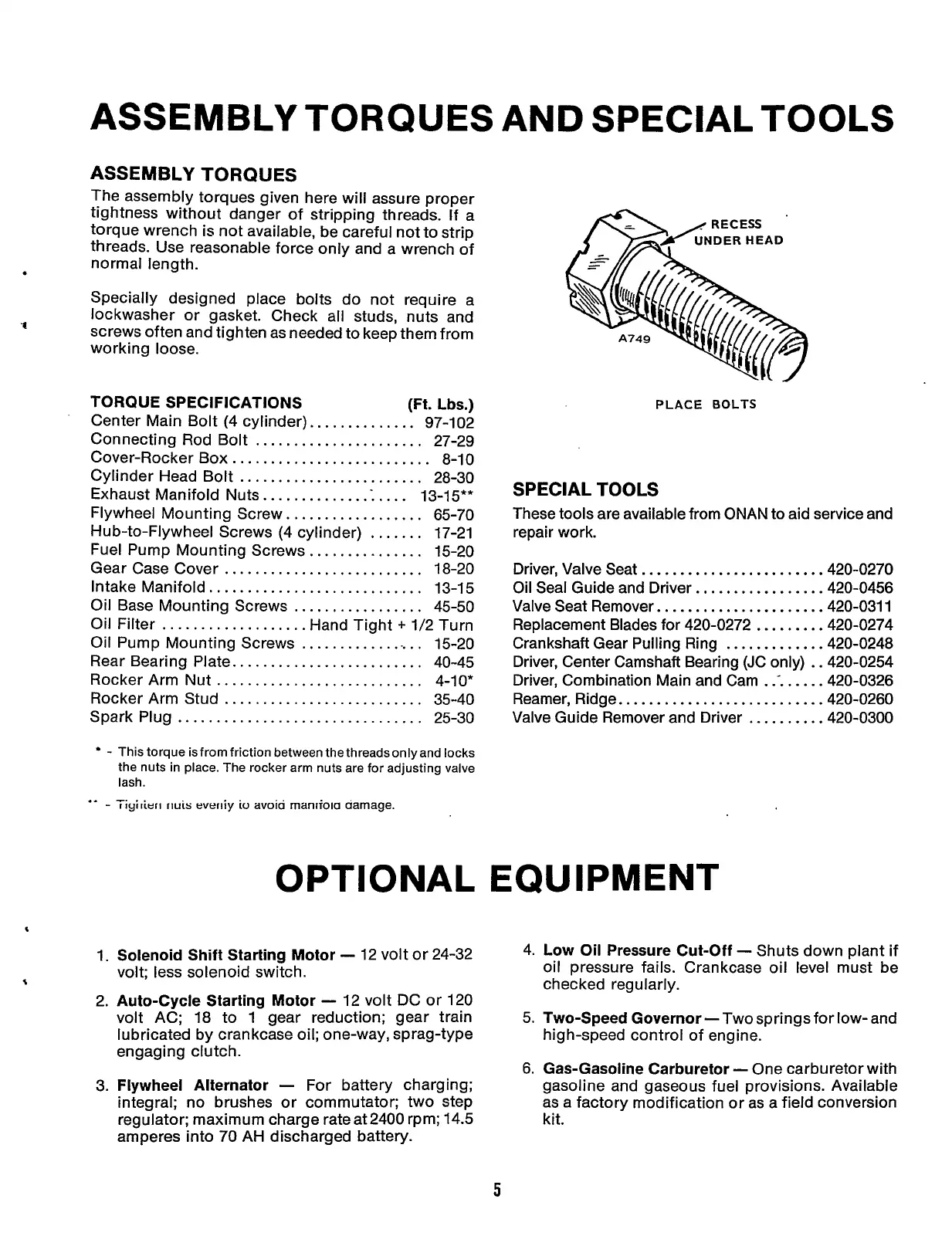

Specially designed place bolts do not require a

lockwasher or gasket. Check all studs, nuts and

screws often and tighten as needed to keep them from

working loose.

1

TORQUE SPECIFICATIONS (Ft. Lbs.)

Center Main Bolt

(4

cylinder).

.............

97-102

Connecting Rod Bolt

......................

27-29

Cover-Rocker Box

..........................

8-10

Cylinder Head Bolt

........................

28-30

Exhaust Manifold Nuts..

..................

13-15**

Flywheel Mounting Screw.

.................

65-70

Hub-to-Flywheel Screws

(4

cylinder)

.......

17-21

Fuel Pump Mounting Screws..

.............

15-20

Gear Case Cover

..........................

18-20

Intake Manifold.

...........................

13-15

Oil Base Mounting Screws

.................

45-50

Oil Filter

...................

Hand Tight

+

1/2

Turn

Oil Pump Mounting Screws

.................

15-20

Rear Bearing Plate..

.......................

40-45

Rocker Arm Nut..

.........................

4-IO*

Rocker Arm Stud

..........................

35-40

Spark Plug

................................

25-30

PLACE

BOLTS

SPECIAL

TOOLS

These tools are available from

ONAN

to aid service and

repair work.

Driver, Valve Seat

.......................

.420-0270

Oil Seal Guide and Driver..

..............

.420-0456

Valve Seat Remover.

....................

.420-0311

Replacement Blades for

420-0272

........

.420-0274

Crankshaft Gear Pulling Ring

............

.420-0248

Driver, Center Camshaft Bearing (JC only)

.

.420-0254

Driver, Combination Main and Cam

........

.420-0326

Reamer, Ridge.

.........................

.420-0260

Valve Guide Remover and Driver

.........

.420-0300

-

This torque isfrorn friction between thethreadsonlyand locks

the nuts in place. The rocker arm nuts are

for

adjusting valve

lash.

-

I

lyiliari

riuis

averiiy

io

avoia

rnaniioio oarnage.

..

-.

OPTIONAL EQUIPMENT

1.

Solenoid Shift Starting Motor

-

12

volt or

24-32

volt; less solenoid switch.

2.

Auto-Cycle Starting Motor

-

12

volt DC or

120

volt AC;

18

to

1

gear reduction; gear train

lubricated by crankcase oil; one-way, sprag-type

engaging clutch.

3.

Flywheel Alternator

-

For

battery charging;

integral; no brushes or commutator; two step

regulator; maximum charge rate at

2400

rpm;

14.5

amperes into

70

AH discharged battery.

4.

Low Oil Pressure Cut-Off

-

Shuts down plant if

oil pressure fails. Crankcase oil level must be

checked regularly.

5. Two-Speed Governor

-

Two springs for low- and

high-speed control of engine.

6.

Gas-Gasoline Carburetor

-

One carburetor with

gasoline and gaseous fuel provisions. Available

as a factory modification or

as

a field conversion

kit.

5

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...