inward). Drive the new seal flush with the-rearsurface

of the bearing plate. Leave the seal installeron during

bearing plate installation to protect the oil seal.

Lubricate lips with heavy (high temperature) grease.

Install the crankshaft as follows. After each step, turn

the crankshaft to be sure

it

has not seized.

1.

Press front and rear main bearings into place;

align bearing and bearing housing oil holes.

Do

not attempt to drive a bearing into a cold block or

rear bearing plate. Install thrust washers and

locking pins.

2.

Oil bearing surfaces and install crankshaft from

rear

of

crankcase, through

rear bearing plate

hole.

3. Mount and secure rear bearing plate with same

thickness of new gaskets as removed.

4. Heat crank gear to about 350°F. Install key on

crankshaft, then drive gear into place. Install

retaining washer and lock ring.

5.

FOUR

CYLINDER

ONLY.

Set upper half

of

center

main housing

on

crankshaft and rotate it into

place. Be sure side marked FRONT is toward

crankshaft gear. Set two positioning dowels on

upper bearing mount. Install center main bearing

cap and torque bolts to

97-102

Ib. ft. (Figure

86).

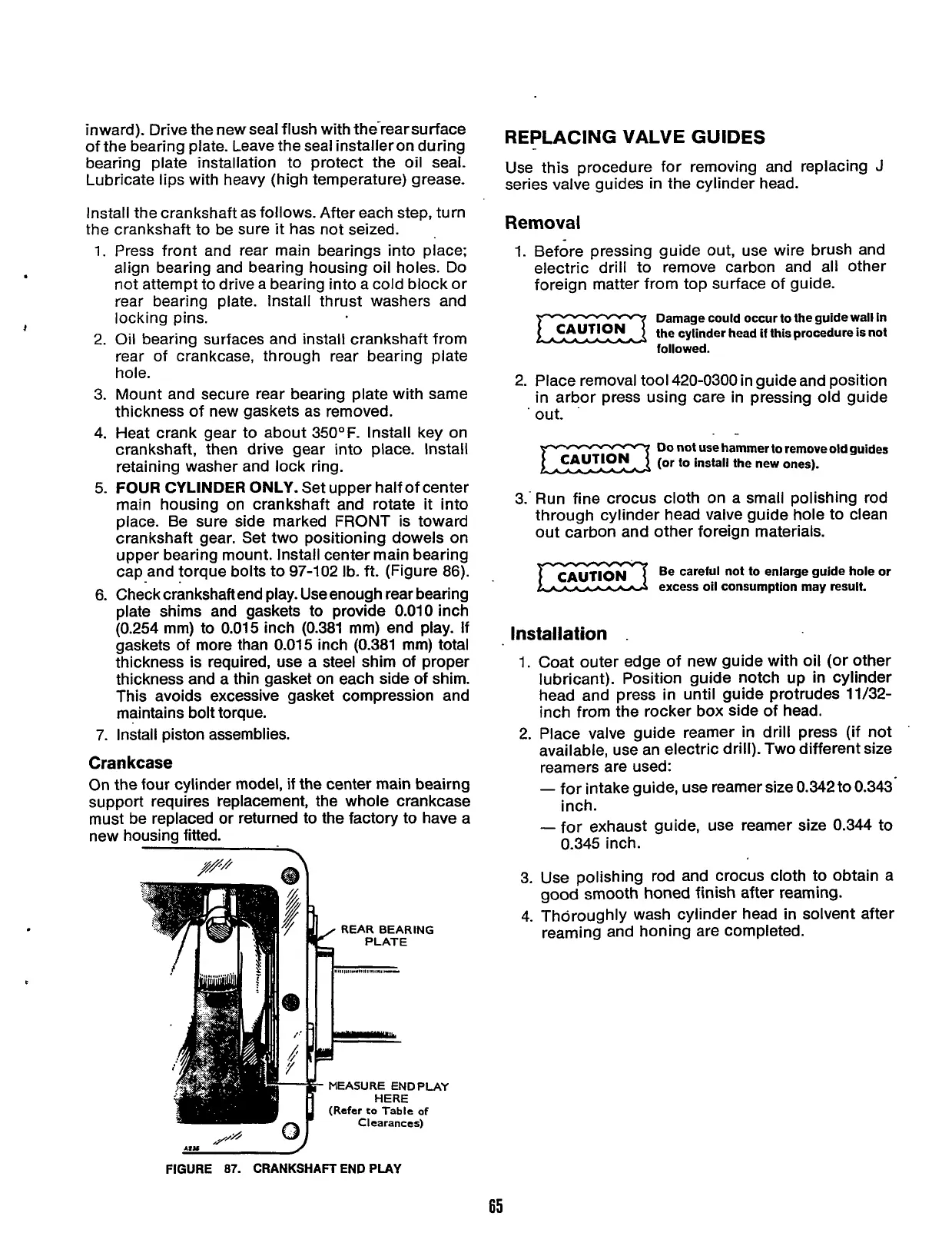

6.

Check crankshaft end play. Useenough rear bearing

plate shims and gaskets to provide

0.010

inch

(0.254 mm) to

0.015

inch

(0.381

mm) end play.

If

gaskets of more than

0.015

inch

(0.381

mm) total

thickness is required, use a steel shim of proper

thickness and a thin gasket on each side of shim.

This avoids excessive gasket compression and

maintains bolt torque.

7.

Install piston assemblies.

.

4

Crankcase

On the four cylinder model,

if

the center main beairng

support requires replacement, the whole crankcase

must be replaced or returned to the factory to have a

new housing fitted.

P

(Refer

eo

Table

of

Clearances)

REPLACING

VALVE

GUIDES

Use this procedure for removing and replacing

J

series valve guides

in

the cylinder head.

Removal

1.

Before pressing guide out, use wire brush and

electric drill to remove carbon and all other

foreign matter from top surface of guide.

Damage could occur to the guide wall in

the cylinder head

if

this procedure

is

not

followed.

2.

Place removal tool 420-0300 in guide and position

in arbor press using care in pressing old guide

.

out.

.-

Do

not

use

hammer to remove old guides

(or to install the new ones).

3.' Run fine crocus cloth on a small polishing rod

through cylinder head valve guide hole to clean

out carbon and other foreign materials.

Be careful not to enlarge guide hole or

excess oil consumption

may

result.

Installation

.

1.

Coat outer edge of new guide with oil (or other

lubricant). Position guide notch up

in

cylinder

head and press in until guide protrudes

11/32-

inch from the rocker box side of head.

2.

Place valve guide reamer in drill press (if not

available, use an electric drill). Two different size

reamers are used:

-

for intake guide, use reamer size

0.342

to

0.343-

-

for exhaust guide, use reamer size 0.344 to

inch.

0.345 inch.

3. Use polishing rod and crocus cloth to obtain a

4. Thoroughly wash cylinder head

in

solvent after

good

smooth honed finish after reaming.

reaming and honing are completed.

I,y

,/

WJ

FIGURE

87.

CRANKSHAFT END

PLAY

65

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...