Three different types of ignition systems cover the

manual- and electric-starting models on two- and

four-cylinder engines. The manual-starting two-

cylinder model

(JB-M)

uses a magneto system. The

two -cy

I

i

n

d e r rem

o

te and e

I

ec t r

i

c

-s

ta rt

i

n g en g

in

es

(JB-R, JB-E) use a battery ignition system. The four-

cylinder model (JC) uses a battery ignition system

with an automotive distributor. For details of specially

suppressed systems (not covered here), request

su p p ression draw

i

n g

.

TESTING

Remove each plug, install the ignition wire to each

plug and hold the plug base against bare engine

metal. Crank the engine and watch the spark. A good

blue spark indicates a healthy ignition system, a weak

or yellow spark or no spark indicates a poor ignition

system. Defective ignition can be caused by defective

breaker points, coil condenser, or wiring. A good

spark on all but one cylinder indicates a defective

spark plug or a defective high tension wire.

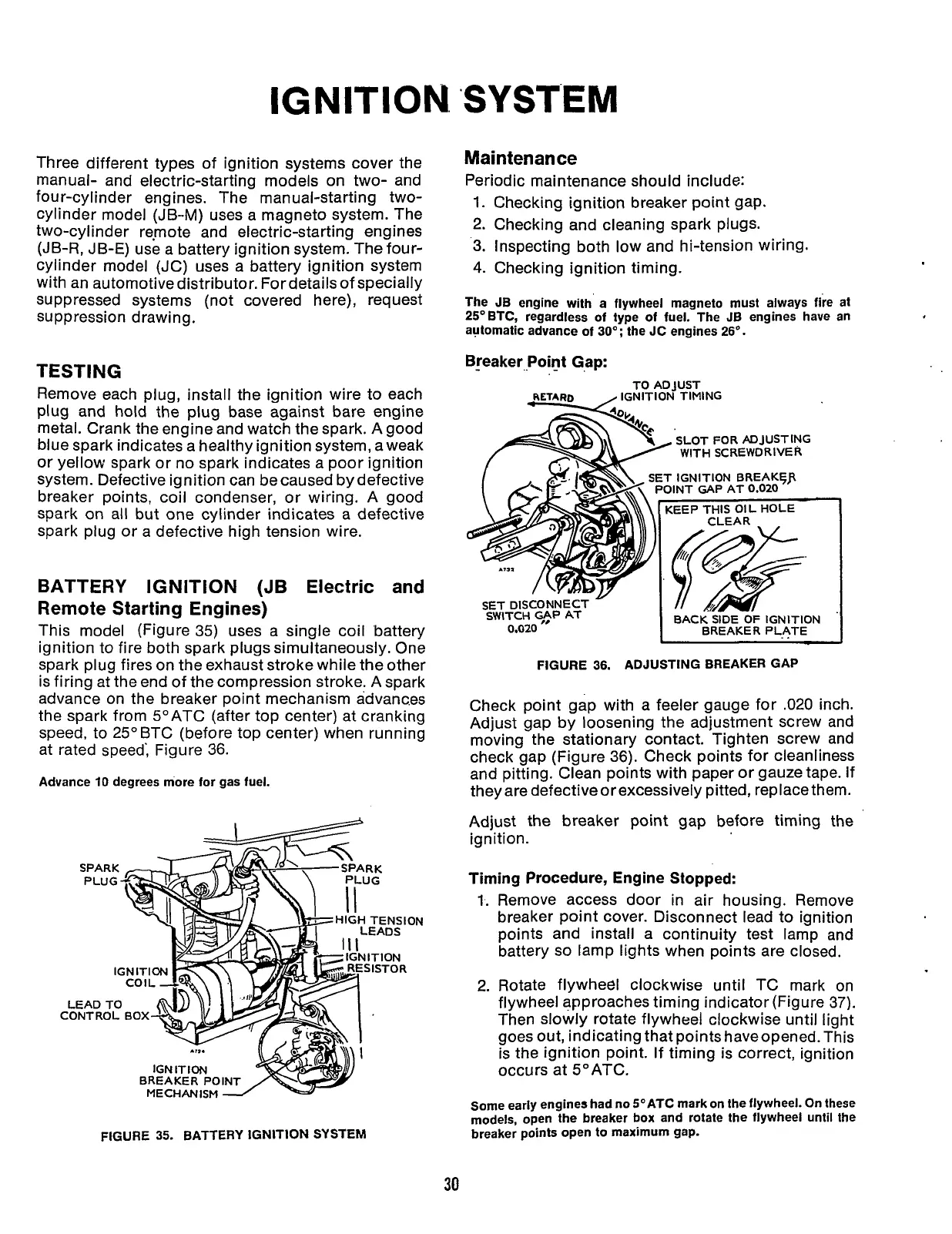

BATTERY IGNITION

(JB

Electric and

Remote Starting Engines)

This model (Figure 35) uses a single coil 'battery

ignition to fire both spark plugs simultaneously. One

spark plug fires on the exhaust stroke while the other

is firing at the end of the compression stroke.

A

spark

advance on the breaker point mechanism advanc.es

the spark from SOATC (after top center) at cranking

speed, to

25"

BTC (before top center) when running

at rated speed; Figure 36.

Advance

10

degrees more for gas fuel.

CONTROL

BOX

Maintenance

Periodic maintenance should include:

1.

Checking ignition breaker point gap.

2.

Checking and cleaning spark plugs.

3.

Inspecting both low and hi-tension wiring.

4.

Checking ignition timing.

The JB engine with a flywheel magneto must always fire at

25"BTC, regardless

of

type

of

fuel. The JB engines have an

automatic advance

of

30";

the JC engines 26'.

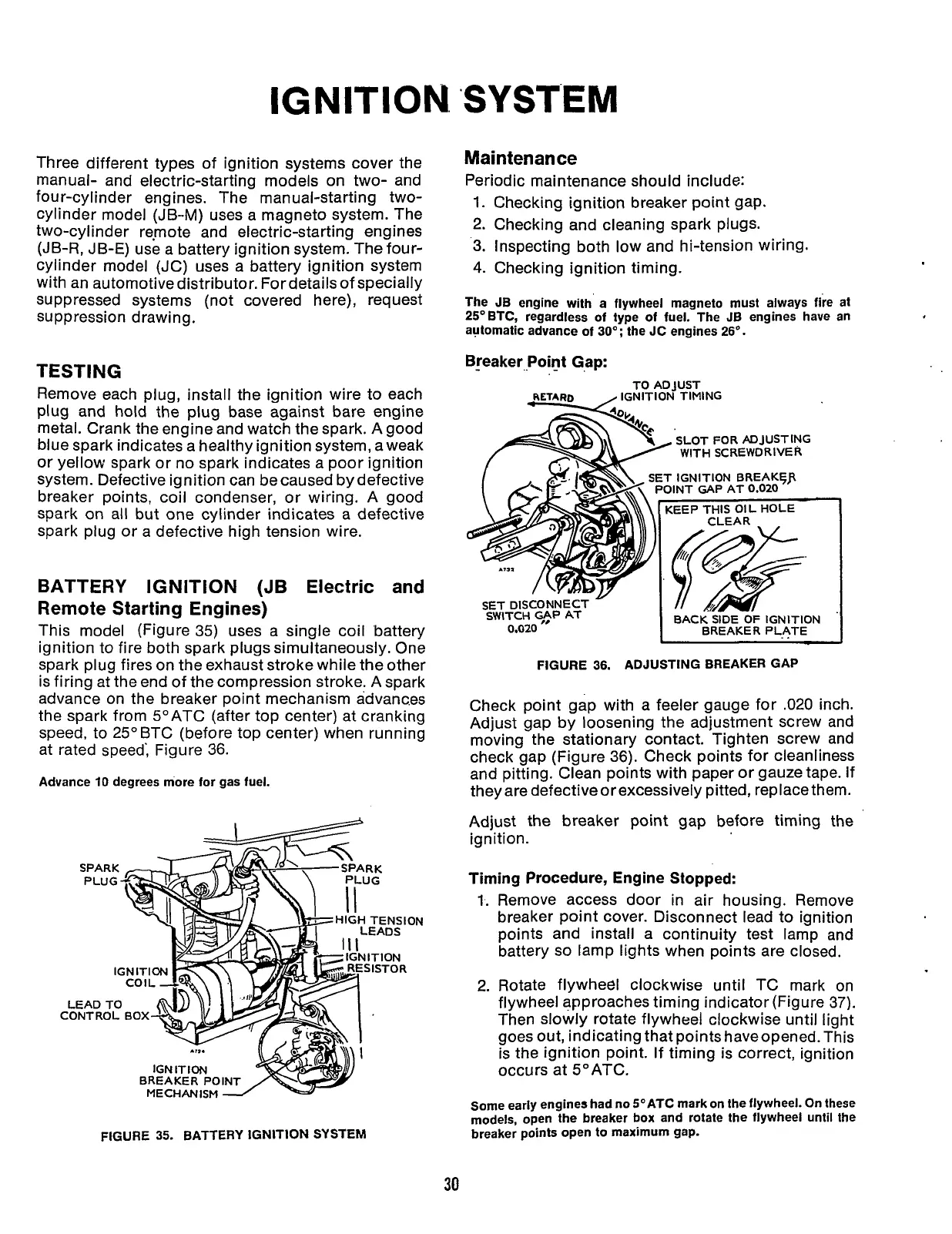

B!eaker_Point Gap:

TO ADJUST

IGNITION TIMING

SLOT

FOR

ADJUSTING

/

WITH

SCREWDRIVER

~

ET

IGNITION BREAKYP

POINT GAP AT

0.020

BACK SIDE

OF

IGNITION

BREAKER PLATE

SET DISCONNECT

SWITCH

qp

AT

0.020

I

..

I

FIGURE

36.

ADJUSTING BREAKER GAP

Check point gap with a feeler gauge for

.020

inch.

Adjust gap by loosening the adjustment screw and

moving the stationary contact. Tighten screw and

check gap (Figure 36). Check points for cleanliness

and pitting. Clean points with paper or gauze tape. If

they are defective or excessively pitted, replace them.

Adjust the

breaker point gap before timing the

ignition.

Timing Procedure, Engine Stopped:

1.

Remove access door in air housing. Remove

breaker point cover. Disconnect lead to ignition

points and install a continuity test lamp and

battery

so

lamp lights when points are closed.

2.

Rotate flywheel clockwise until TC mark on

flywheel approaches timing indicator (Figure

37).

Then slowly rotate flywheel clockwise until light

goes out, indicating that points haveopened. This

is the ignition point. If timing is correct, ignition

occurs at 5"ATC.

FIGURE

35.

BATTERY IGNlTlON SYSTEM

Some early engines had no VATC mark on the flywheel. On these

models, open the breaker box and rotate the flywheel until the

breaker points open to maximum gap.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...