ENGINE

DISASSEMBLY

AND

REPAIR

Intake

Exhaust

This section covers the various assemblies and parts

Of the engine. All repairs should be done by a

competent mechanic.

Maintain factory limits and

clearances (see

Dimensions and Clearances

section).

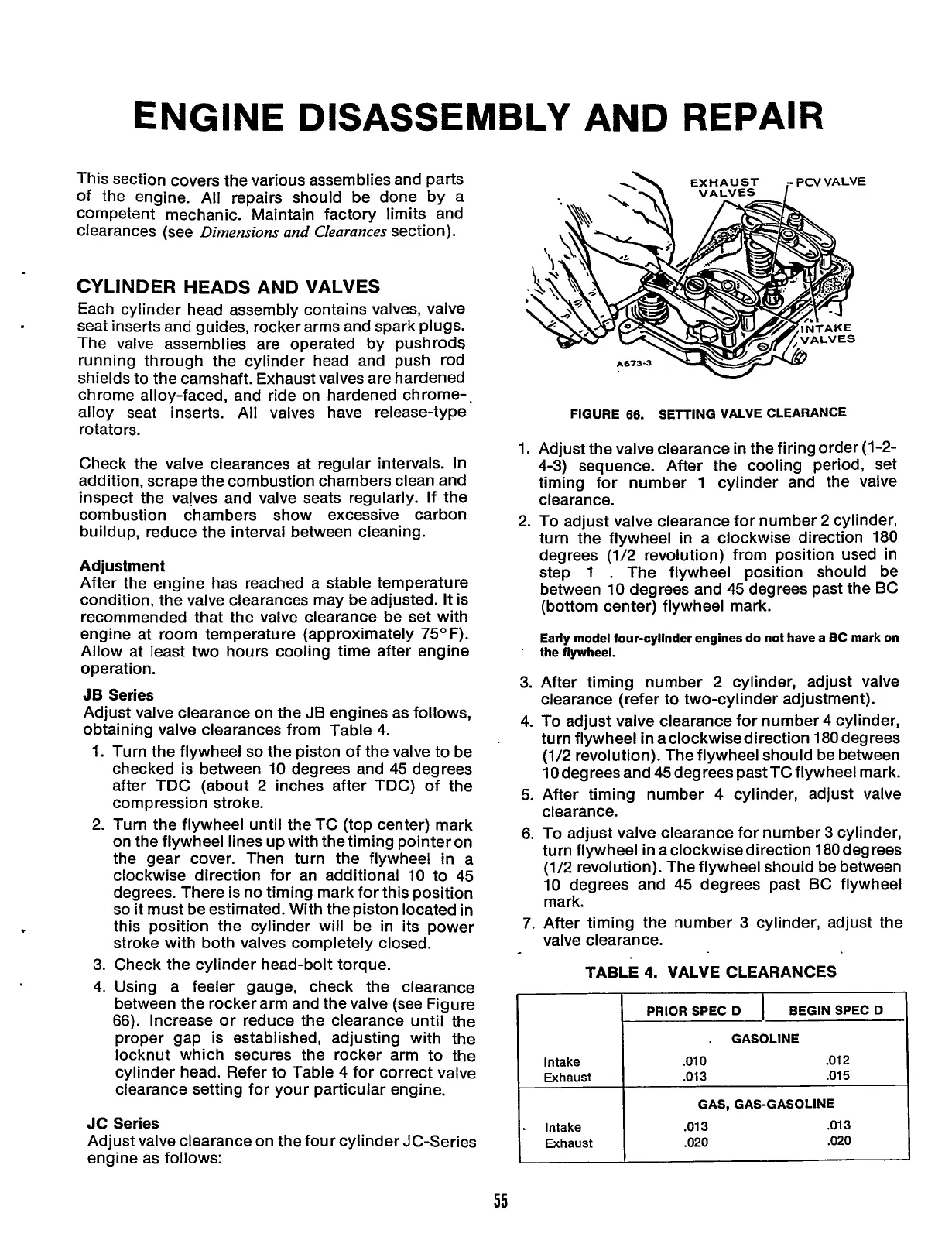

PRIOR

SPEC

D

BEGIN SPEC

D

.

GASOLINE

.010

.012

.013

.015

GAS, GAS-GASOLINE

CYLlNDER HEADS AND VALVES

Each cylinder head assembly contains valves, valve

seat inserts and guides, rocker arms and spark plugs.

The valve assemblies are operated by pushrods

running through the cylinder head and push rod

shields to the camshaft. Exhaust valves are hardened

chrome alloy-faced, and ride on hardened chrome-.

alloy seat inserts. AI1 valves have release-type

rotators.

Check the valve clearances at regular intervals.

In

addition, scrape the combustion chambers clean and

inspect the valves and valve seats regularly. If the

combustion chambers show excessive carbon

buildup, reduce the interval between cleaning.

Adjustment

After the engine has reached a stable temperature

condition, the valve clearances may be adjusted.

It

is

recommended that the valve clearance be set with

engine at room temperature (approximately

75O

F).

Allow at least two hours cooling time after engine

operation.

JB

Series

Adjust valve clearance on the

JB

engines as follows,

obtaining valve clearances from Table 4.

1.

Turn the flywheel

so

the piston of the valve to be

checked is between 10 degrees and 45 degrees

after TDC (about 2 inches after TDC) of the

co m p ression stroke.

2. Turn the flywheel until the TC (top center) mark

on the flywheel lines up with thetiming pointeron

the gear cover. Then turn the flywheel

in

a

clockwise direction for an additional 10 to

45

degrees. There is no timing mark for this position

so

it must be estimated. With the piston located in

this position the cylinder will be in its power

stroke with both valves completely closed.

3. Check the cylinder head-bolt torque.

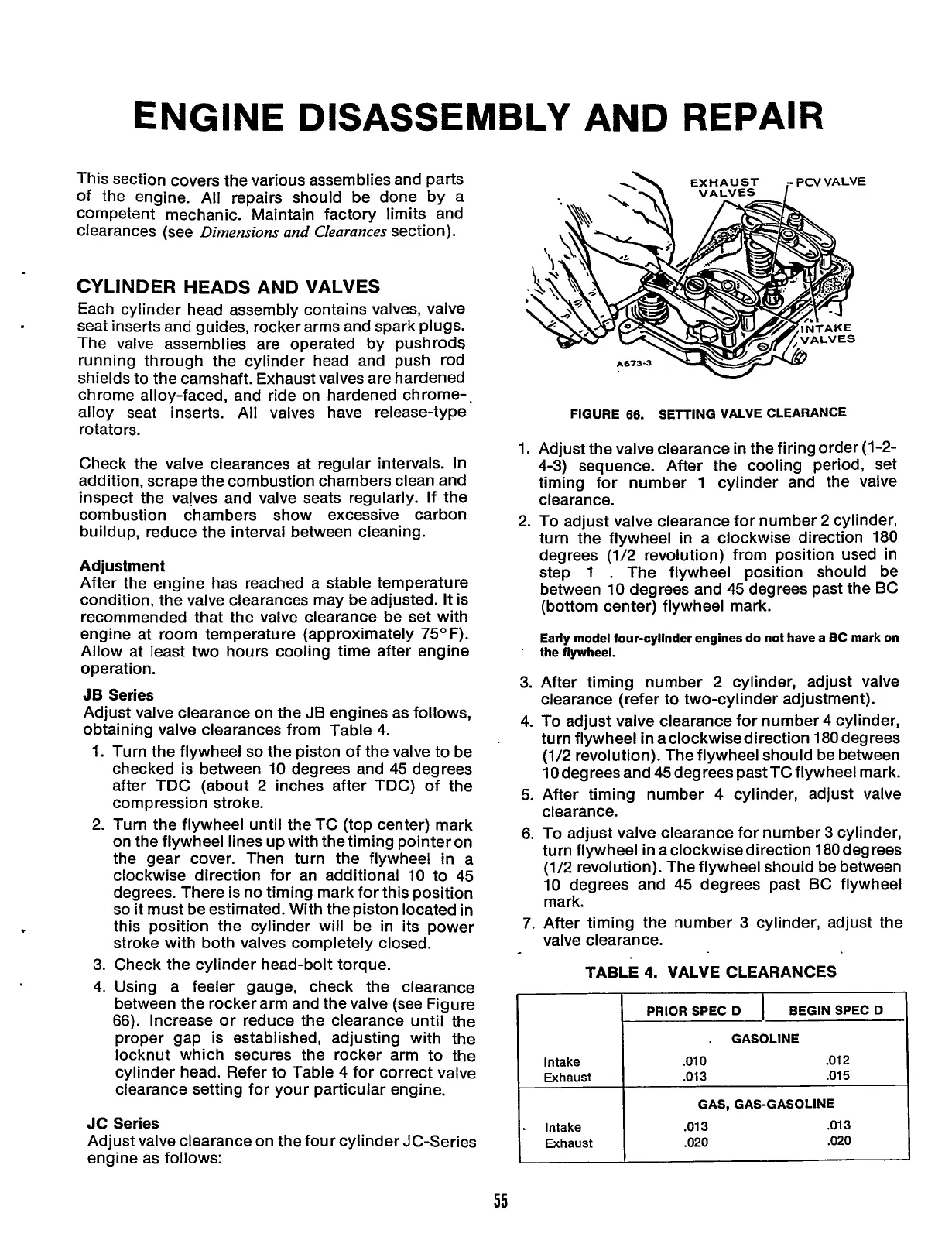

4. Using a feeler gauge, check the clearance

between the rocker arm and the valve (see Figure

66).

Increase or reduce the clearance until the

proper gap is established, adjusting with the

locknut which secures the rocker arm to the

cylinder head. Refer to Table 4 for correct valve

clearance setting for your particular engine.

JC Series

Adjust valve clearance on the four cylinder JC-Series

engine as follows:

W

FIGURE

66.

SETTING VALVE CLEARANCE

.

Intake

I

Exhaust

I

.013

.020

I

I

I

55

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...