Tighten distributor

in

its mount and recheck

timing.

If

the relative position

of

the timing marks

doesn’t remain steady, the distributor

may be defective. This can be caused by pitted

or

misaligned

breaker points, incorrect breaker point spring tension,

worn

or

loose

breaker plate, or

a

worn

distributor shaft

or

bushing.

Distributor: The distributor contains and opens the

breaker points at the proper time, contains an

automatic spark advance mechanism, and distributes

the spark to the proper cylinder.

Testing: Remove the distributor and test

it

on a

commercial tester. Following the equipment

manufacturer’s instructions, check the centrifugal

advance mechanism and cam dwell angle. The cam

dwell angle should be

51

+3

degrees.

Do

not set

breaker gap by cam dwell. With the proper point gap,

if cam dwell is outside the above limits, check for worn

distributor cam.

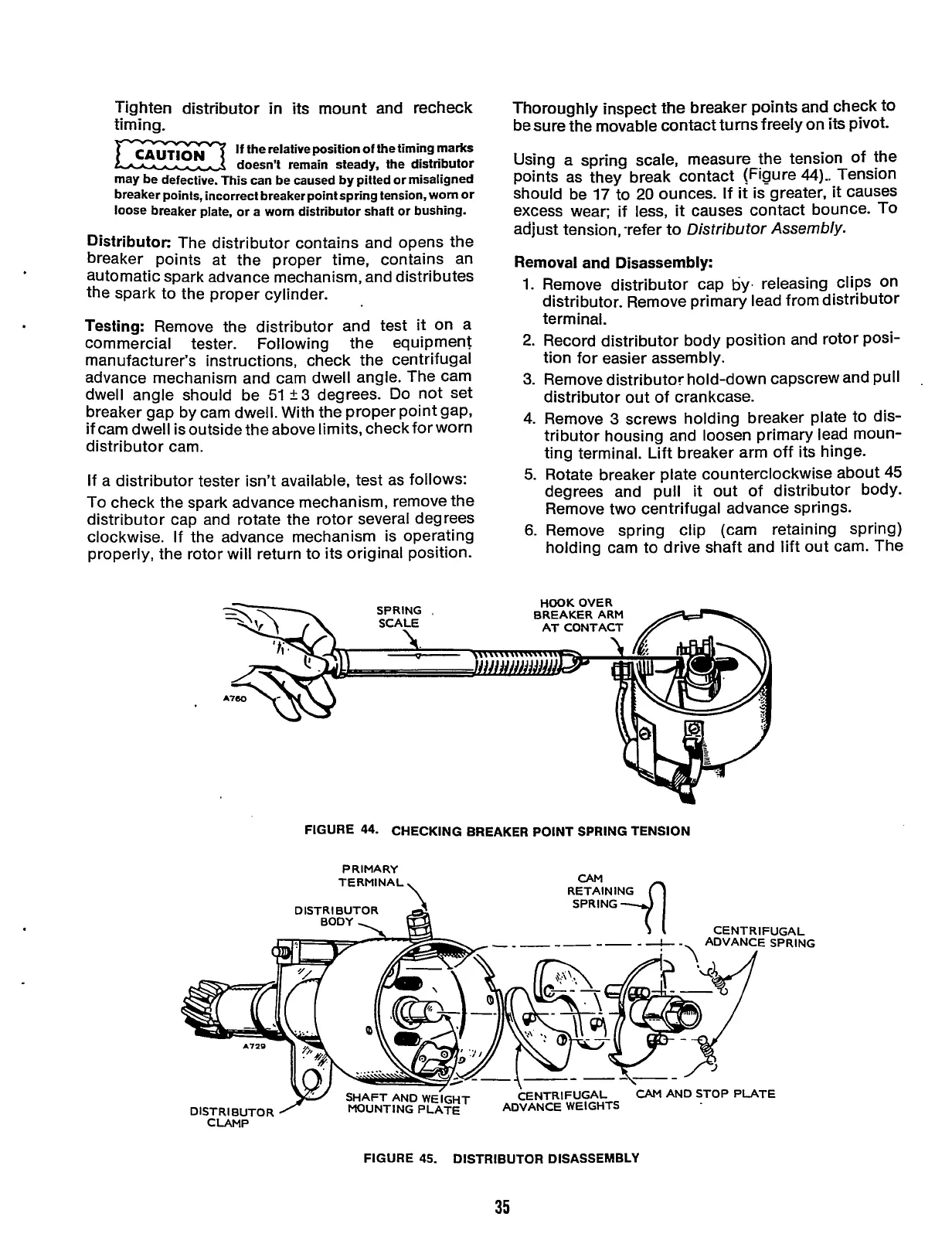

Thoroughly inspect €he breaker points and check to

be sure

€he

movable contact turns freely on its pivot.

Using

a

spring scale, measure the tension of the

points as they break contact (Figure

a)..

Tension

should be

17

to

20

ounces. If

it

is greater,

it

causes

excess wear;

if

less,

it

causes contact bounce. To

adjust tension, -refer to

Distributor

Assembly.

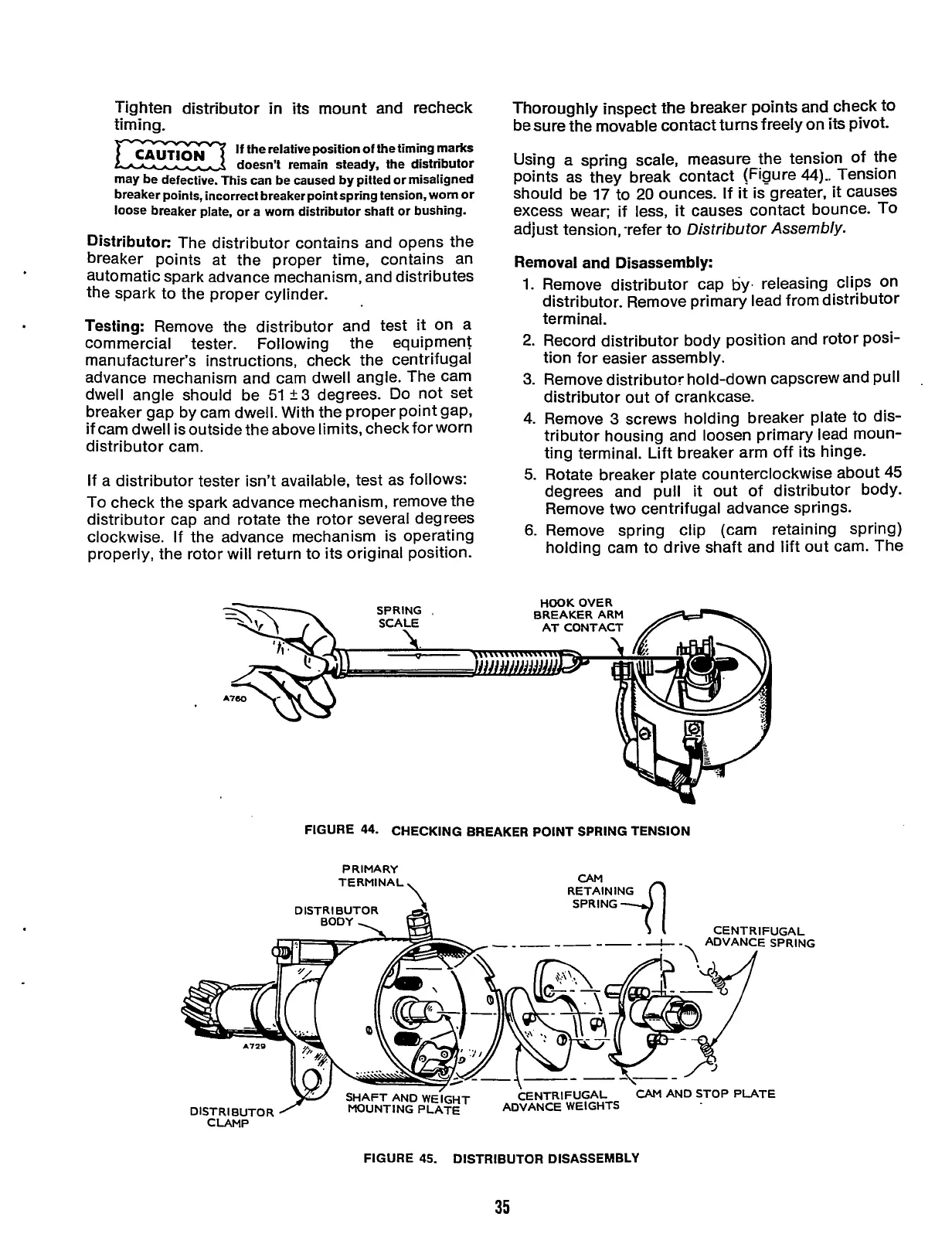

Removal

and

Disassembly:

1.

Remove distributor cap by. releasing clips On

distributor. Remove primary lead from distributor

terminal.

2.

Record distributor body position and rotor pOSi-

tion for easier assembly.

3.

Remove distributor hold-down capscrew and pull

distributor out of crankcase.

4.

Remove

3

screws holding breaker plate to dis-

tributor housing and loosen primary lead moun-

ting terminal. Lift breaker arm off its hinge.

.

If a distributor tester isn’t available, test as follows:

To check the spark advance mechanism, remove the

distributor cap and rotate the rotor several degrees

clockwise.

If

the advance mechanism is operating

properly, the rotor will return to its original position.

5.

Rotate breaker plate counterclockwise about

45

degrees and pull

it

out of distributor body.

Remove two centrifugal advance springs.

6.

Remove spring clip (cam retaining spring)

holding cam to drive shaft and lift out cam. The

HOOK

OVER

BREAKER ARM

AT CONTACT

FIGURE

44-

CHECKING BREAKER POINT SPRING TENSION

PRIMARY

TERMINAL

CENTRIFUGAL

DISTRIBUTOR

DlSTRlBUTOR

CLAMP

FIGURE

45.

DISTRIBUTOR DISASSEMBLY

35

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...