7.

8.

weights are now free and can be lifted out (Figure

451).

To

remove drive shaft, grind or file off peened-

Over end of pin holding drive gear to shaft. Drive

out pin, then remove gear and pull shaft out

through distributor body.

If

necessary, press two bronze bearings out of

distributor body.

3.

Set centrifugal advance weights into place and

install cam. Be sure pivots on cam fit into hole

in

each weight. Secure cam with spring clip and

install weight springs.

4.

Install and secure breaker plate.

5.

Mount breaker arm on its pivot and place control

spring end between end of terminal stud and

square metal washer. Then tighten primary ter-

minal.

Repair:

Clean all components except the condenser,

breaker points and bushings in light cleaning solvent.

Inspect the centrifugal advance component for signs

of wear and replace any that appear worn or

otherwise damaged, Inspect the cam and shaft for

wear or score marks. If either is scored, replace it.

’

To

check bearing wear, set the drive shaft into the

body and measure the side play at the top of the cam

with a dial indicator. Mount the indicator on the

distributor body, and measure the side play by pulling

the shaft directly away from the indicator with a force

of about five pounds. Side play should be less than

.005

inch. If not, the bearings must be replaced.

ONAN

does not recommend field replacement of

bronze shaft bearings unless the required equipment

is available. This can be done by an authorized service

station.

Distributor Assembly:

Install shaft assembly with upper drive shaft

thrust washer

in

distributor body. Install lower

drive shaft thrust washer and drive gear. Install a

pin through drive gear and shaft and peen it into

place.

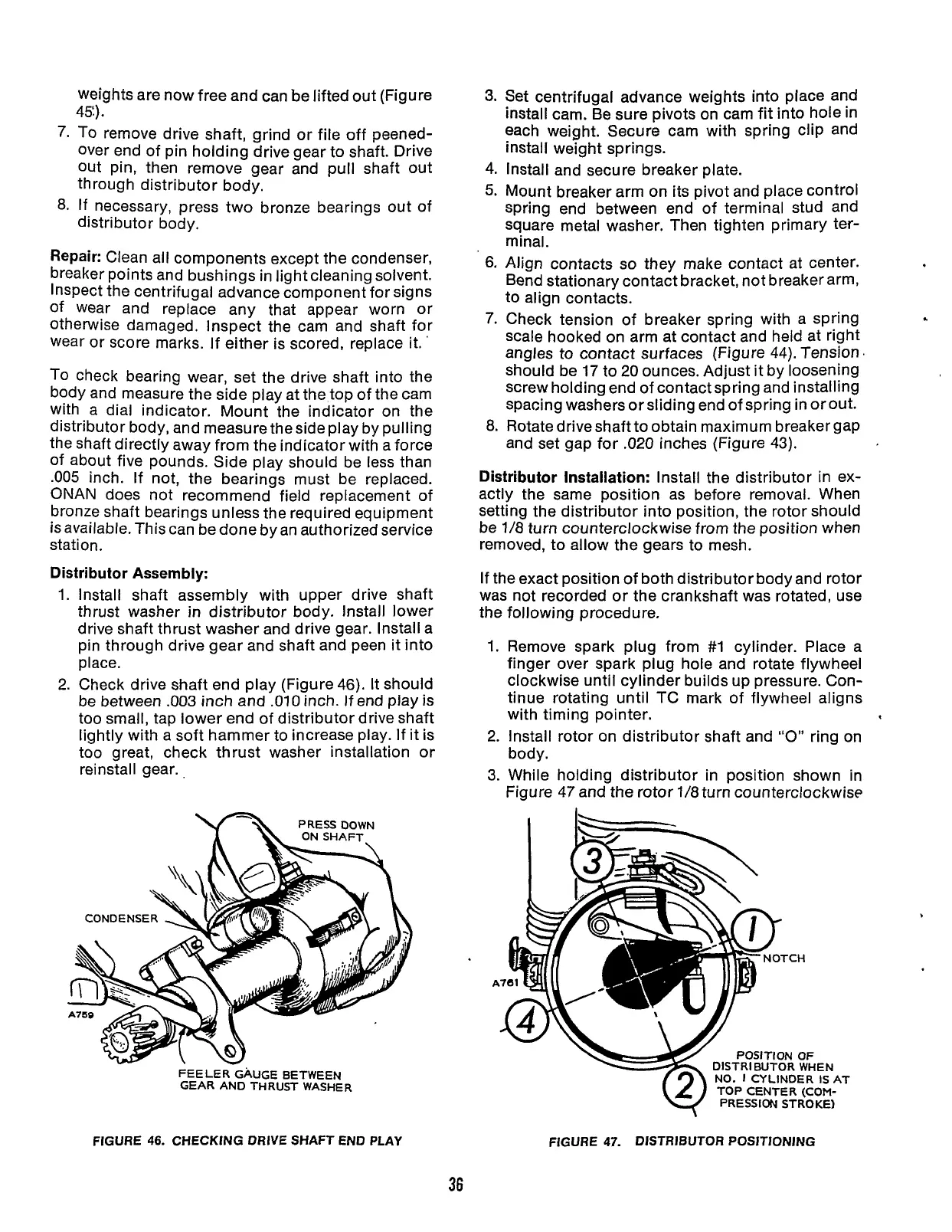

Check drive shaft end play (Figure

46).

It should

be between

.003

inch and

.010

inch. If end play is

too small, tap lower end of distributor drive shaft

lightly with a soft hammer to increase play. If

it

is

too great, check thrust washer installation or

reinstall gear.,

PRESSDOWN

ON SHAFT

FEELERGAUGE

BETWEEN

GEAR

AND THRUST WASHER

6.

Align contacts

so

they make contact at center.

Bend stationary contact bracket, not breaker arm,

to align contacts.

7.

Check tension of breaker spring with a spring

scale hooked on arm at contact and held at right

angles to contact surfaces (Figure

44).

Tension

should be

17

to

20

ounces. Adjust it by loosening

screw holding end of contactspring and installing

spacing washers orsliding end of spring in or out.

8.

Rotate drive shaft to obtain maximum breaker gap

and set gap for

.020

inches (Figure

43).

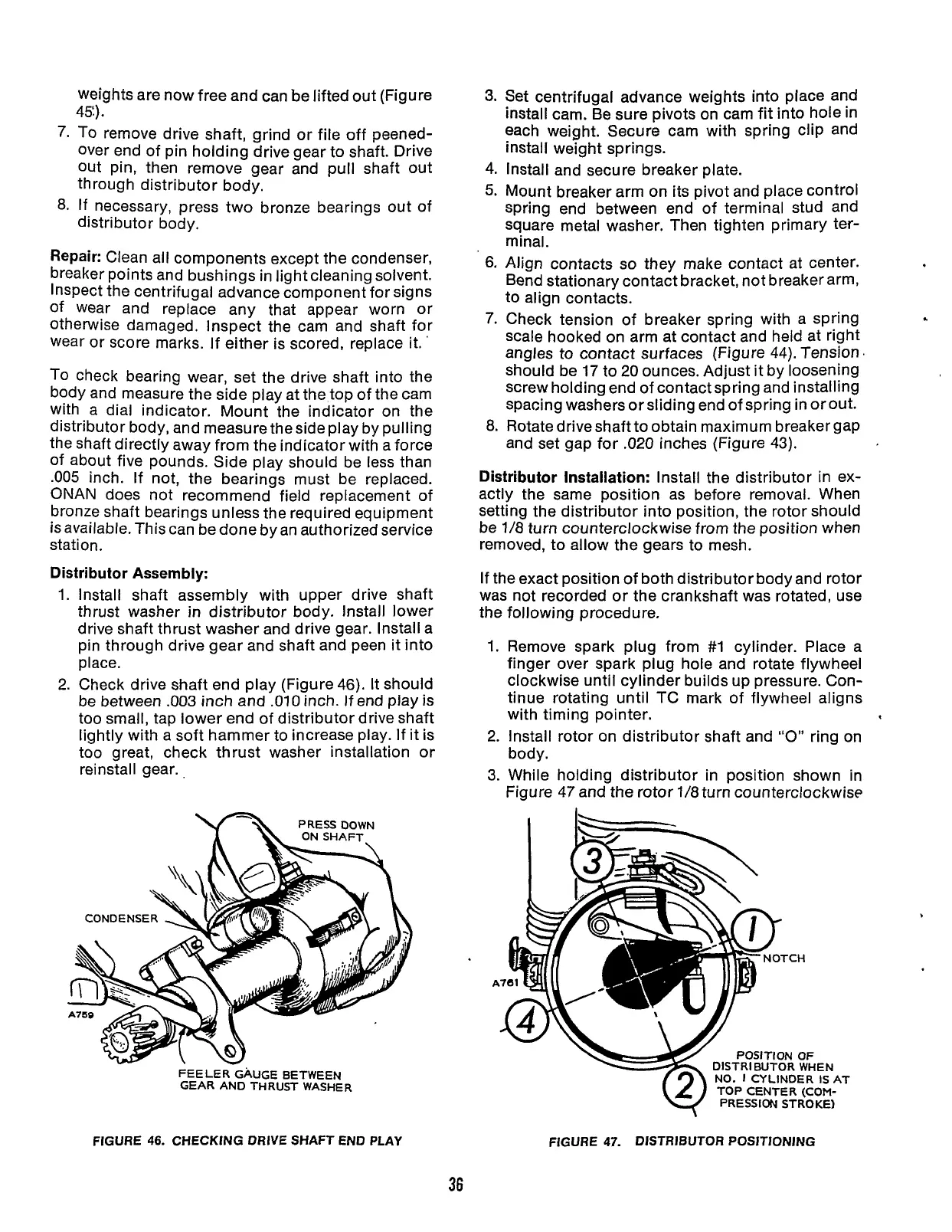

Distributor Installation:

Install the distributor in ex-

actly the same position as before removal. When

setting the distributor into position, the rotor should

be

118

turn counterclockwise from the position when

removed, to allow the gears to mesh.

If the exact position of both distributor body and rotor

was not recorded or the crankshaft was rotated, use

the following procedure.

1.

Remove spark plug from

#1

cylinder. Place a

finger over spark plug hole and rotate flywheel

clockwise until cylinder builds up pressure. Con-

tinue rotating until TC mark of flywheel aligns

with timing pointer.

2.

Install rotor on distributor shaft and

“0”

ring on

body.

3.

While holding distributor in position shown in

Figure

47

and the rotor

1/8

turn counterclockwise

POSITION

OF

DlSTRl

BUTOR

WHEN

NO.

I

CYLINDER

IS

AT

TOP CENTER (COM-

PRESSION STROKE)

FIGURE

46.

CHECKING DRIVE

SHAFT

END

PLAY

FIGURE

47.

DISTRIBUTOR POSITIONING

36

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...