FUEL

SEDIMENT

Empty carburetor and fuel filter (strainer) bowls of

any accumulated sediment. Clean filter screen

thoroughly. Reassemble and check for leaks.

GASOLINE

FUEL

Use regular grade automobile gasoline. Do not use

highly leaded premium types. Never fill the tank when

the engine is running. Leave some tank space for fuel

expansion.

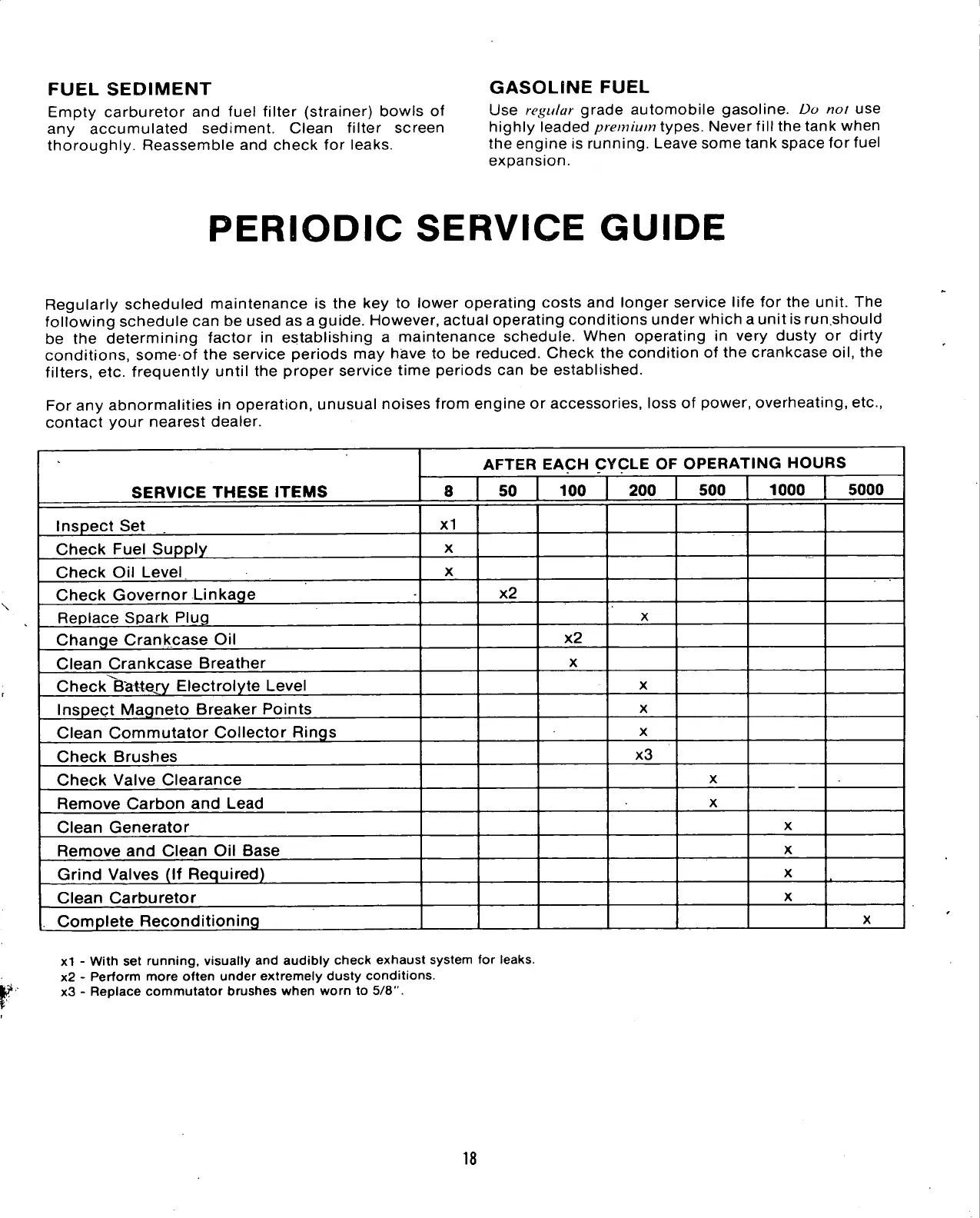

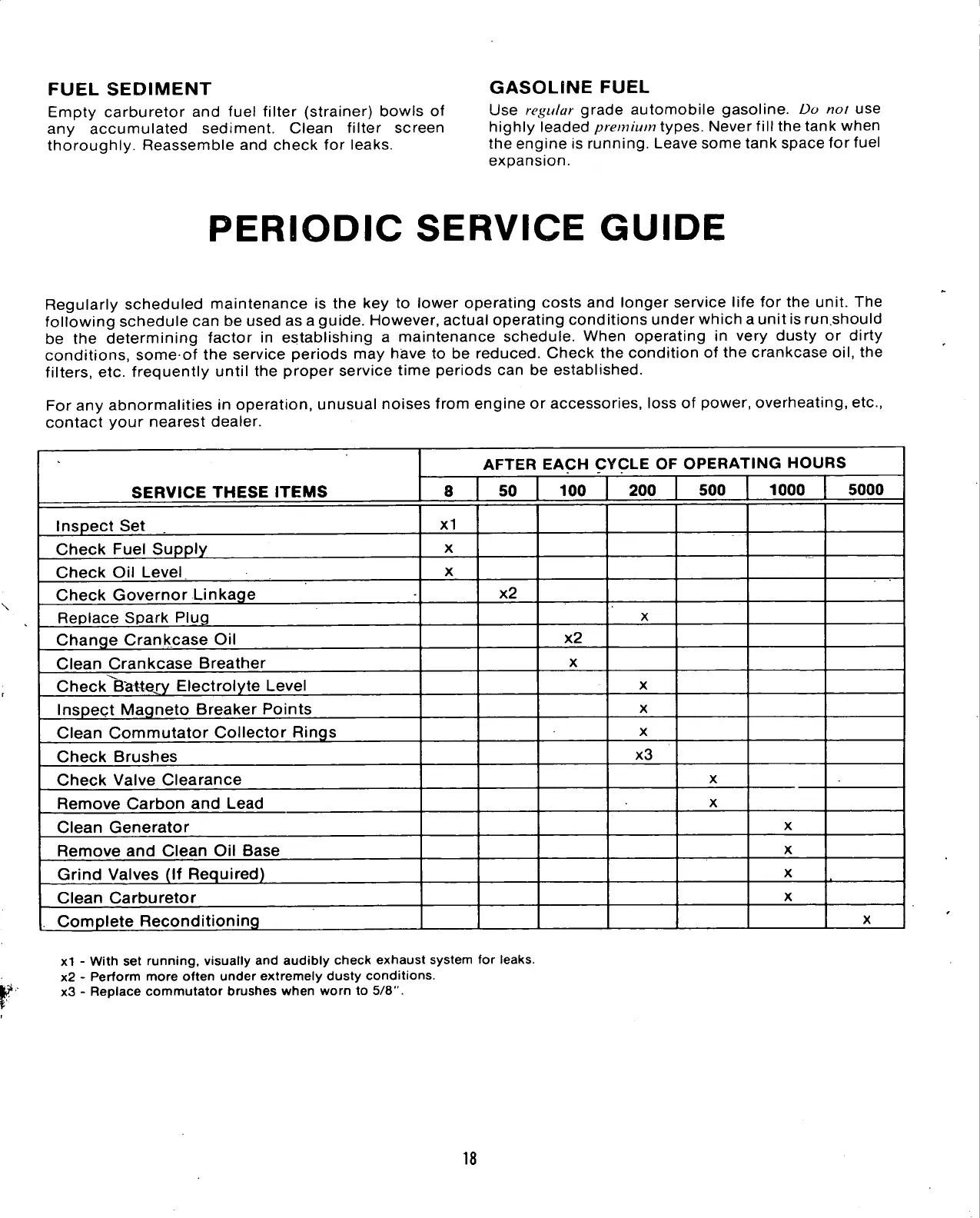

PERIODIC

SERVICE

GUIDE

Regularly scheduled maintenance is the key to lower operating costs and longer service life for the unit. The

following schedule can be used as a guide. However, actual operating conditions under which a unit is run.should

be the determining factor in establishing a maintenance schedule. When operating in very dusty or dirty

conditions, some of the service periods may have to be reduced. Check the condition of the crankcase oil, the

filters,

etc. frequently until the proper service time periods can be established.

For any abnormalities in operation, unusual noises from engine or accessories, loss of power, overheating, etc.,

contact your nearest dealer.

SERVICE THESE

ITEMS

AFTER EACH CYCLE

OF

OPERATING

HOURS

SERVICE THESE

ITEMS

8

50 100

200 500

1000

5000

Inspect Set

xl

Check Fuel Supply

X

Check Oil Level

X

Check Governor Linkage

x2

Replace Spark Plug

x

Change Crankcase Oil

x2

Clean Crankcase Breather

X

Checkl&rttery Electrolyte Level

X

Inspect Magneto Breaker Points

X

Clean Commutator Collector Rings

X

Check Brushes

x3

Check Valve Clearance

X

Remove Carbon and Lead

X

Clean Generator

X

Remove and Clean Oil Base

X

Grind Valves (If Required)

X

Clean Carburetor

X

Complete Reconditioning

X

xl - With set running, visually and audibly check exhaust system for leaks.

x2 - Perform more often under extremely dusty conditions.

x3 - Replace commutator brushes when worn to 5/8".

18

Loading...

Loading...