Cooling

System

INSPECTION

As a part of standard maintenance procedures, the

entire cooling system should be inspected for signs

of leakage and checked for worn components. In-

spect the water pump bearings, impeller (neoprene),

and seals for signs of wear, and check for correct

drive belt tension. Locate the source

of

any leaks and

correct as required. Inspect

the

zinc pencils on heat-

exchanger cooled engines, and note the amount of

deterioration. Refer to the appropriate section for

recommended service procedures.

As a final check, run the engine at full load and verify

that the engine can maintain an operating tempera-

ture of approximately 18OOF (82'C). An engine that

operates significantly above

or

below this value

should be tested for malfunctions.

IMPORTANCE

OF

REGULAR

MAINTENANCE

The entire cooling system, including the block and

radiator, heat exchanger,

or

keel cooler should be

cleaned and flushed out at least once a year. This is

especially important in cold weather conditions

or

when preparing the unit for extended storage (over

30

days). The cooling system can work efficiently

only when it is clean.

A

build-up of rust and scale

in

the cooling system will slow down heat absorption

and restrict water flow.

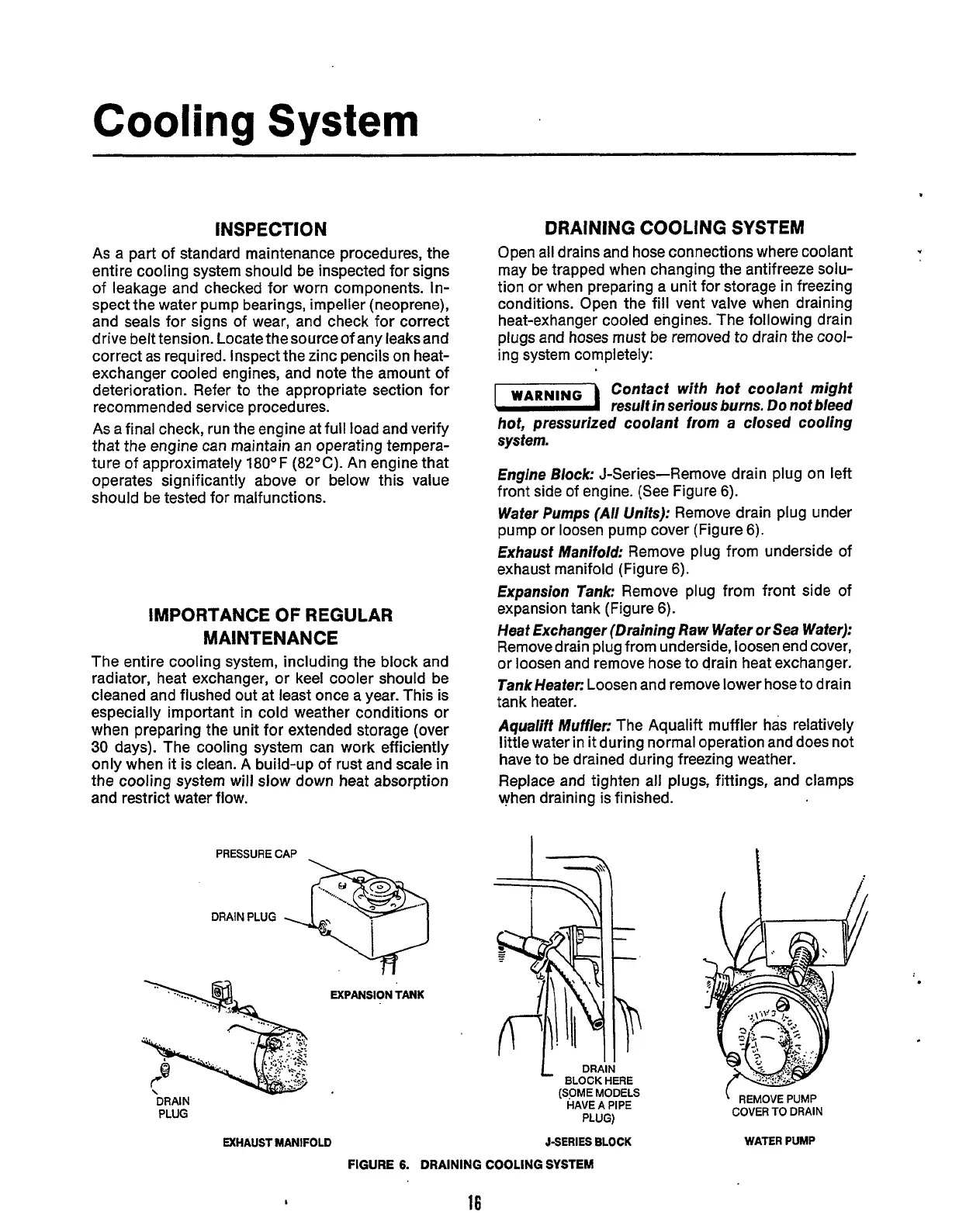

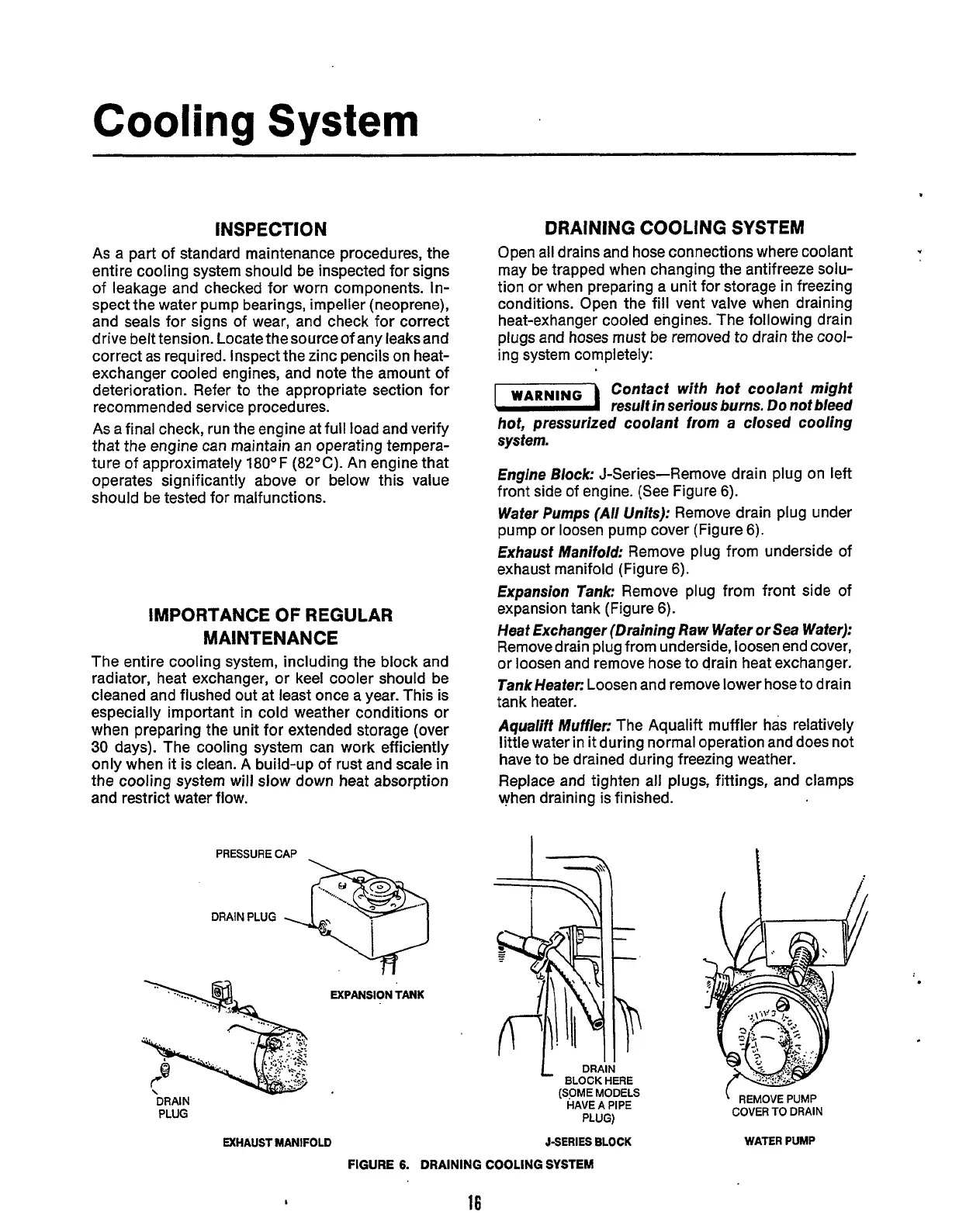

PRESSURE CAP

DRAIN

PLUG

DRAINING COOLING SYSTEM

Open all drains and hose connections where coolant

may be trapped when changing

the

antifreeze solu-

tion

or

when preparing a unit for storage in freezing

conditions. Open the fill vent valve when draining

heat-exhanger cooled engines. The following drain

plugs and hoses must be removed to drain the

cool-

ing system completely:

Contact with

hof

coolanf might

n

result in serious burns.

Do

not

bleed

hof,

pressurized coolant

from

a closed cooling

sysfem.

Engine

Block: J-Series-Remove drain plug on

left

front side of engine.

(See

Figure

6).

Wafer

Pumps

(All

Unifs);

Remove drain plug under

pump

or

loosen pump cover (Figure

6).

Exhaust Manifold:

Remove plug from underside of

exhaust manifold (Figure

6).

Expansion Tank:

Remove plug from front side of

expansion tank (Figure

6).

Heat Exchanger (Draining Raw Water or Sea Wafer):

Removedrain plug from underside, loosen end cover,

or

loosen and remove hose to drain heat exchanger.

TankHeafer:

Loosen and remove lower hose to drain

tank heater.

Aqualiff Muffler;

The Aqualift muffler

has

relatively

little water in it during normal operation and does not

have to be drained during freezing weather.

Replace and tighten all plugs, fittings, and clamps

when draining is finished.

t

L

DRAIN

BLOCK

HERE

(SOME

MODELS

HAVE

A

PIPE

PLUG)

EXHAUST

MANIFOLD

J-SERIES

BLOCK

FIGURE

6.

DRAINING COOLING

SYSTEM

REMOVEPUMP

COVER

TO

DRAIN

WATER

PUMP

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...