Governor

System

The purpose of the engine governor

is

to maintain a

constant engine speed during changes in power

demands.

A

governor responds to changes in power

demands by varying the throttle position.

A

constant-

speed governor is standard on marine engines.

GOVERNORS

The constant-speed governor maintains enginespeed

up to

2400

rpm. The speed-sensing device is a ball

and cup mechanism on the camshaft gear. A yoke,

resting on the cup, is connected to the throttle lever.

Any change in engine speed is transmitted from the

cup to the yoke, and on to the throttle.

Tension on thegovernor spring determines thespeed

at which the engine is controlled. Astud screwed into

thespring isused tovarythenumberofeffectivecoils

for getting the desired sensitivity-the speed drop

from no-load to full-load.

Maintenance

Periodically lubricate the metal governor Iinkagewith

lubricating graphite or light non-gumming oil. Also,

inspect the governor linkage for binding or excessive

slack or wear. Plastic ball joint socket does not need

lubrication.

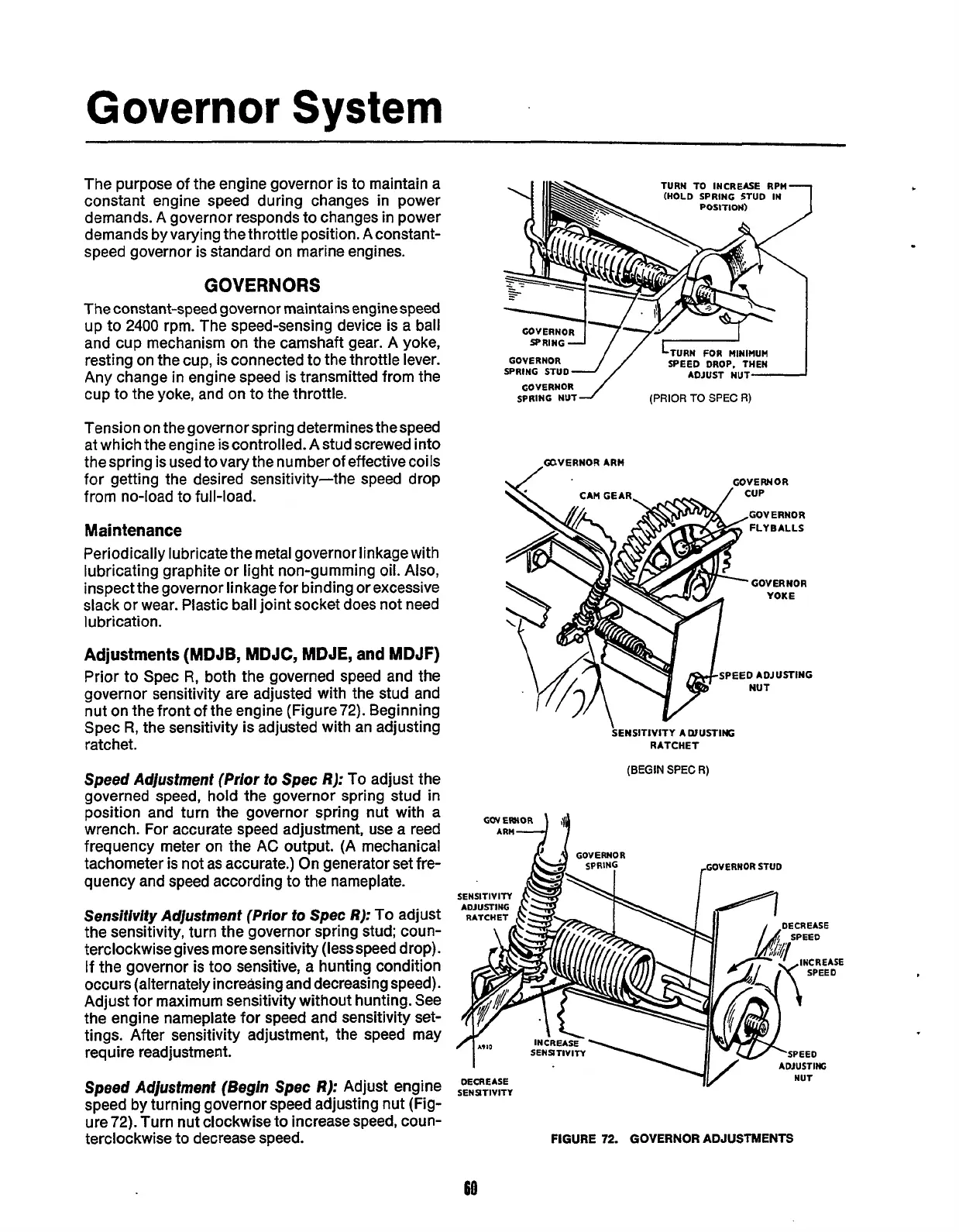

Adjustments (MDJB, MDJC, MDJE, and MDJF)

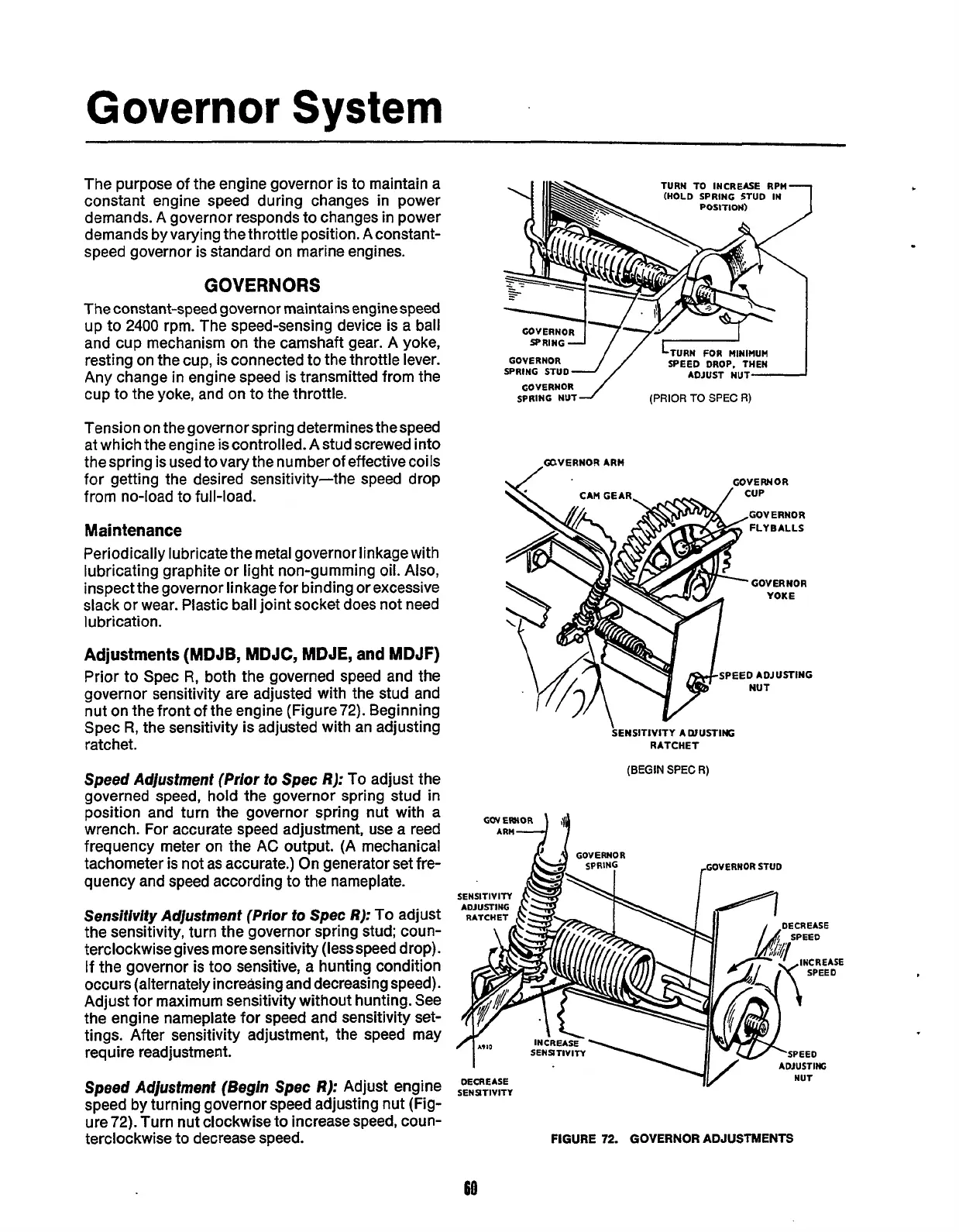

Prior to Spec

R,

both the governed speed and the

governor sensitivity are adjusted with the stud and

nut on the front of the engine (Figure72). Beginning

Spec

R,

the sensitivity is adjusted with an adjusting

ratchet.

Speed Adjustment

(Prior

to

Spec

R):

To

adjust the

governed speed, hold

the

governor spring stud in

position and turn the governor spring nut with a

wrench. For accurate speed adjustment, use a reed

frequency meter on the

AC

output.

(A

mechanical

tachometer is not as accurate.) On generator set fre-

quency and speed according to the nameplate.

Sensiflvity

Adjustment

(Prior

to

Spec

R):

To

adjust

the sensitivity, turn the governor spring stud; coun-

terclockwise gives more sensitivity (lessspeed drop).

If

the governor is too sensitive, a hunting condition

occurs (alternately increasing and decreasing speed).

Adjust for maximum sensitivity without hunting. See

the engine nameplate for speed and sensitivity set-

tings. After sensitivity adjustment, the speed may

require readjustment.

Speed

Adjustment (Begln

Spec

R):

Adjust engine

speed by turning governor speed adjusting nut (Fig-

ure

72).

Turn nut clockwise to increase speed, coun-

terclockwise to decrease speed.

TURN

TO

INCREASE RPM

(HOLD SPRING

STUD

IN

LTURN

FOR

MINIMUM

SPEED DROP. THEN

ADJUST

NUT-

GOVERNOR-

J/

SPRING

STUD

GOVERNOR

1

SPRING

NUT

(PRIOR

TO

SPEC

R)

GUVERNORARH

\/

’

GOVERNOR

GOVERNOR

YOKE

PEED ADJUSTING

NUT

SENSITIVITY

A

CUUSTlffi

RATCHET

(BEGIN

SPEC

R)

ARM

9

GOVERHOR

STUD

SENSTIVITY

FIGURE

72.

GOVERNOR ADJUSTMENTS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...