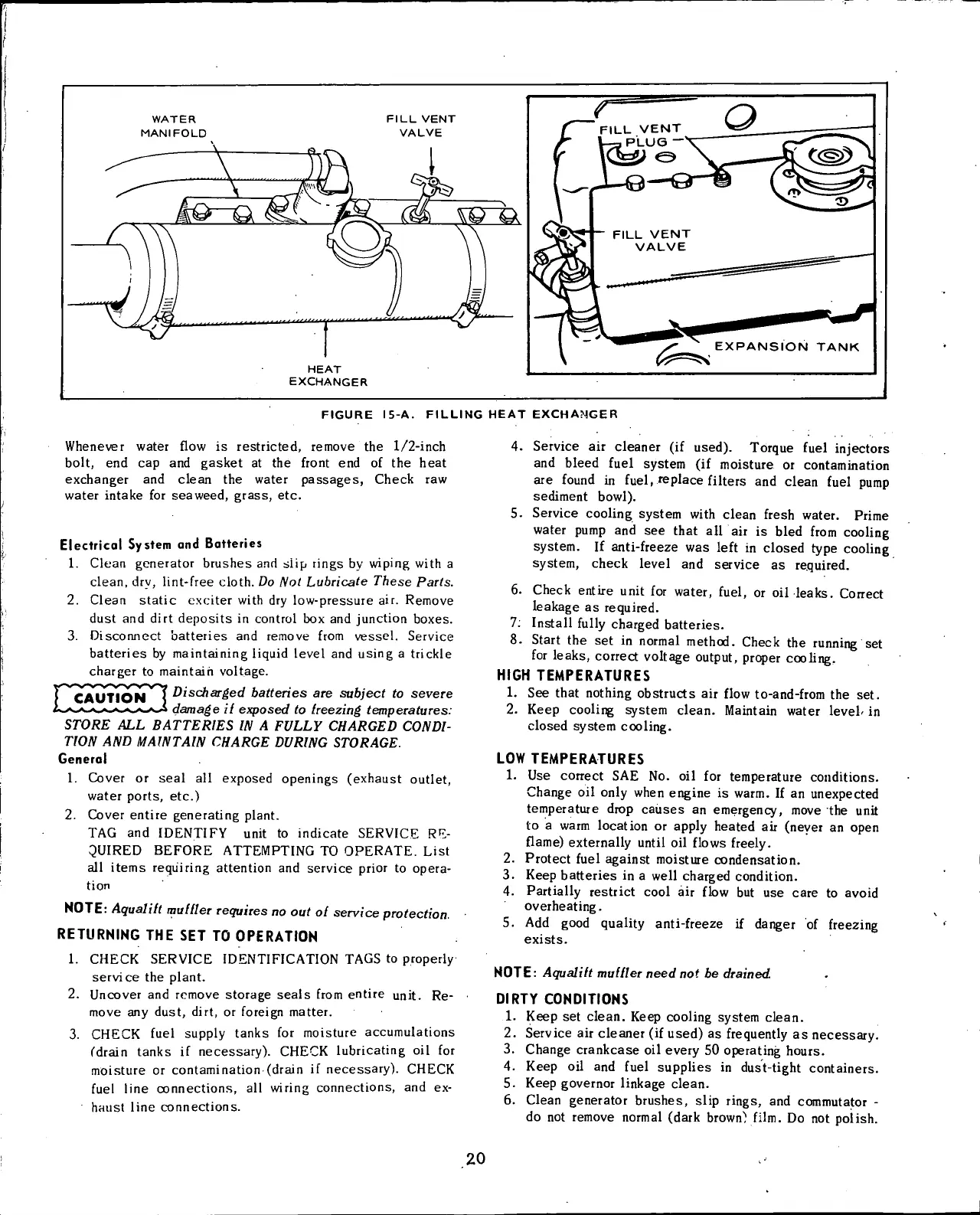

WATER

MANIFOLD

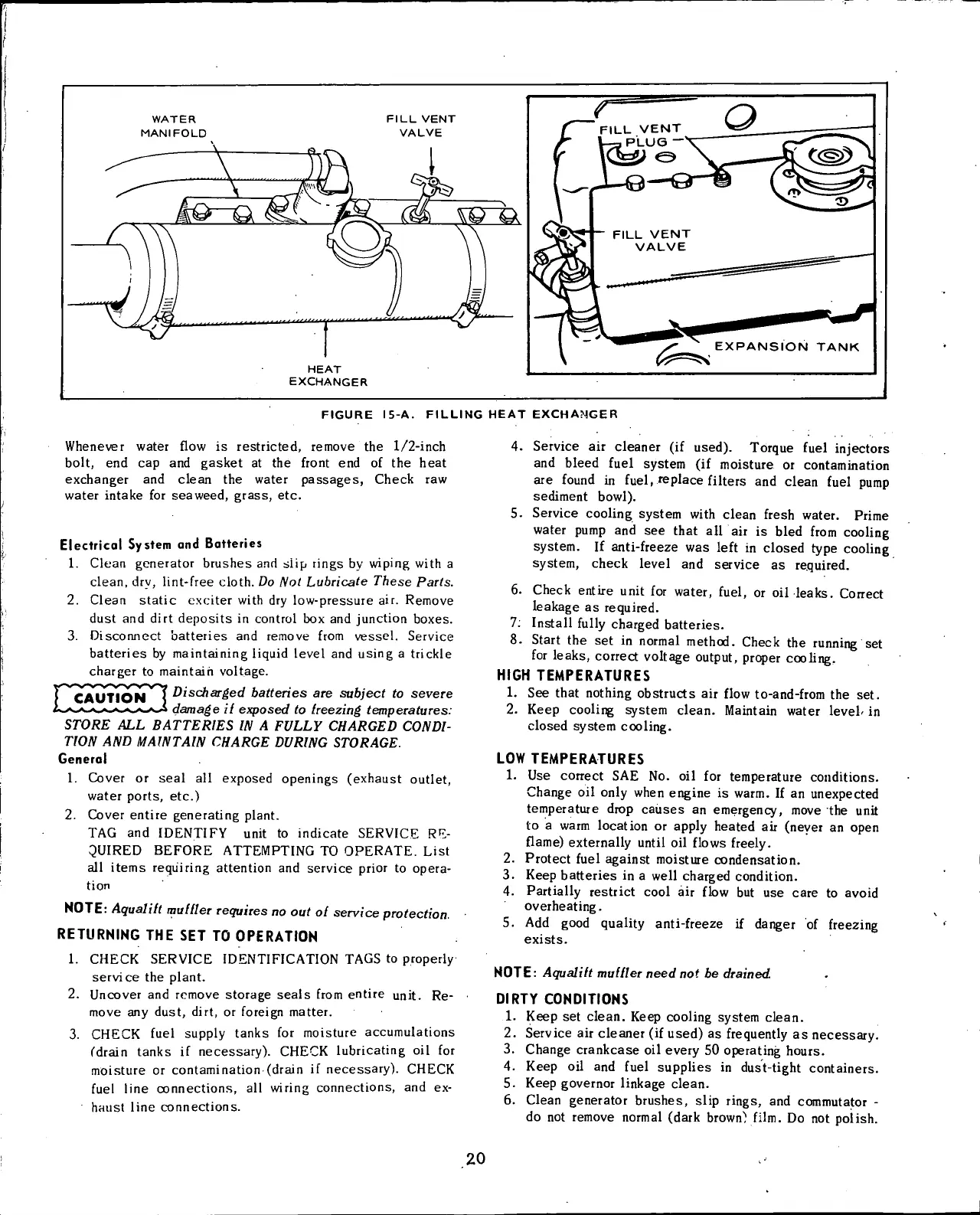

FILL

VENT

VALVE

HEAT

EXCHANGER

EXPANSION

TANK

FIGURE

15-A.

FILLING

HEAT

EXCHA?4GER

Whenever water

flow

is restricted, remove the 1/2-inch

bolt,

end cap and

gasket

at the

front

end of the

heat

exchanger and clean the water

passages,

Check raw

water intake for

seaweed,

grass,

etc.

Electrical

System

and

Batteries

1. Clean generator brushes

and

slip rings

by

wiping with

a

clean,

dry,

lint-free cloth. Do

Not

Lubricate These Parts.

2.

Clean static exciter

with

dry low-pressure air. Remove

dust and

dirt

deposits in

control

box and

junction

boxes.

3. Disconnect batteries and remove

from

vessel. Service

batteries by maintaining

liquid

level

and using a

trickle

charger to maintain voltage.

CAUTION

3

Discharged batteries

are

subject

to

severe

damage

if

exposed

to

freezing temperatures:

STORE

ALL

BATTERIES

IN A

FULLY

CHARGED

CONDI-

TION

AND

MAINTAIN

CHARGE

DURING

STORAGE.

General

1.

Cover or

seal

all exposed openings (exhaust outlet,

water ports, etc.)

2.

Cover entire generating plant.

TAG

and

IDENTIFY

unit

to indicate SERVICE RE-

QUIRED

BEFORE

ATTEMPTING

TO OPERATE.

List

all

items requiring attention and service

prior

to opera-

tion

NOTE:

Aqualilt muffler requires no out of service protection.

RETURNING

THE

SET

TO

OPERATION

1.

CHECK

SERVICE

IDENTIFICATION

TAGS

to properly

service the plant.

2.

Uncover and remove

storage

seals

from

entire

unit.

Re-

move any dust,

dirt,

or

foreign

matter.

3.

CHECK

fuel

supply tanks for moisture accumulations

(drain

tanks if necessary).

CHECK

lubricating

oil for

moisture

or contamination

(drain

if necessary).

CHECK

fuel

line

connections, all

wiring

connections, and ex-

haust

line

connections.

4.

Service air cleaner (if used). Torque

fuel

injectors

and bleed

fuel

system (if moisture or contamination

are

found

in

fuel,

replace

filters

and clean

fuel

pump

sediment

bowl).

5. Service

cooling

system

with

clean fresh water. Prime

water pump and see that all air is bled

from

cooling

system. If anti-freeze was

left

in closed type

cooling

system, check

level

and service as required.

6. Check entire

unit

for water,

fuel,

or oil leaks. Conect

leakage as required.

7:

Install

fully

charged batteries.

8.

Start

the set in normal method.

Check

the running set

for leaks, correct

voltage

output, proper cooling.

HIGH

TEMPERATURES

1.

See that nothing obstructs air

flow

to-and-from

the set.

2.

Keep

cooling

system clean.

Maintain

water

level-

in

closed system

cooling.

LOW

TEMPERATURES

1.

Use correct SAE No. oil for temperature conditions.

Change oil

only

when engine is warm. If an unexpected

temperature drop

causes

an emergency, move the

unit

to

a warm location or apply heated air (never an open

flame)

externally

until

oil

flows

freely.

2.

Protect

fuel

against moisture condensation.

3. Keep batteries in a

well

charged

condition.

4.

Partially restrict

cool

air

flow

but use

care

to

avoid

overheating.

5. Add good

quality

anti-freeze if

danger

of freezing

exists.

NOTE: Aqualift muffler need

not be

drained

DIRTY

CONDITIONS

1.

Keep set clean. Keep

cooling

system clean.

2.

Service air cleaner (if

used)

as frequently as

necessary.

3. Change

crankcase

oil every 50 operating hours.

4.

Keep oil and

fuel

supplies in dust-tight containers.

5. Keep governor linkage clean.

6. Clean generator

brushes,

slip

rings, and commutator -

do not remove normal (dark brown)

film.

Do not

polish.

20

Loading...

Loading...