ADJUSTMENTS

CHECK

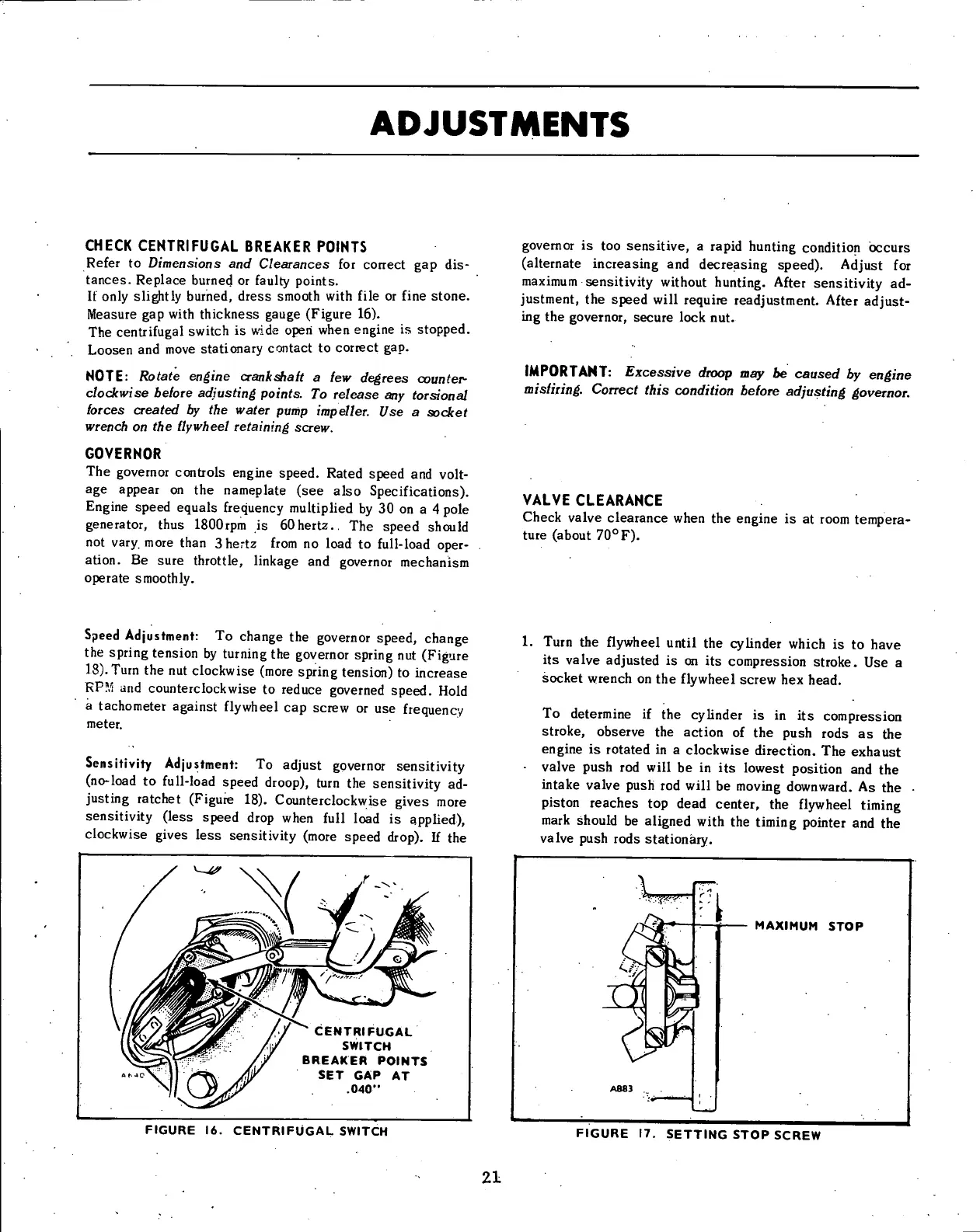

CENTRIFUGAL

BREAKER

POINTS

Refer to Dimensions and

Clearances

for correct gap dis-

tances.

Replace burned or

faulty

points.

If

only

sligjitly

burned,

dress

smooth

with

file

or

fine

stone.

Measure gap

with

thickness

gauge

(Figure 16).

The

centrifugal

switch is wide open when engine is stopped.

Loosen and move stationary contact to correct gap.

NOTE: Rotate engine cranks&alt

a few

degrees counter-

clockwise before adjusting points.

To

release

any

torsional

forces created

by the

water pump impeller.

Use a

socket

wrench

on the

flywheel retaining screw.

GOVERNOR

The governor controls engine

speed.

Rated

speed

and

volt-

age

appear

on the nameplate (see also Specifications).

Engine

speed

equals

frequency

multiplied

by 30 on a 4 pole

generator, thus ISOOrpm is 60hertz.. The

speed

should

not

vary, more than 3 hertz

from

no load to

full-load

oper-

ation.

Be

sure

throttle, linkage and governor mechanism

operate

smoothly.

governor is too sensitive, a rapid hunting condition occurs

(alternate increasing and decreasing

speed).

Adjust for

maximum

sensitivity

without

hunting.

After

sensitivity ad-

justment, the

speed

will

require readjustment.

After

adjust-

ing

the governor,

secure

lock

nut.

IMPORTANT: Excessive droop

may be

caused

by

engine

misfiring. Correct this condition before adjusting governor.

VALVE

CLEARANCE

Check valve

clearance

when the engine is at room tempera-

ture (about

70°

F).

Speed

Adjustment: To

change

the governor

speed,

change

the spring tension by turning the governor spring nut (Figure

18).

Turn

the nut clockwise (more spring tension) to

increase

RPM

and counterclockwise to reduce governed

speed.

Hold

a tachometer against

flywheel

cap screw or use frequency

meter.

Sensitivity

Adjustment: To adjust governor sensitivity

(no-load

to

full-load

speed

droop),

turn

the sensitivity ad-

justing

ratchet (Figure 18). Counterclockwise gives more

sensitivity

(less

speed

drop when

full

load is applied),

clockwise

gives

less

sensitivity (more

speed

drop). If the

CENTRIFUGAL

SWITCH

BREAKER

POINTS

SET

GAP AT

.040"

1.

Turn

the

flywheel

until

the cylinder

which

is to

have

its

valve adjusted is on its compression stroke. Use a

socket wrench on the

flywheel

screw hex head.

To

determine if the cylinder is in its compression

stroke, observe the action of the push rods as the

engine is rotated in a clockwise direction. The exhaust

•

valve push rod

will

be in its lowest position and the

intake valve push rod

will

be moving downward. As the

piston

reaches

top dead center, the

flywheel

timing

mark

should be aligned

with

the

timing

pointer and the

valve

push rods stationary.

A883

.

MAXIMUM

STOP

FIGURE

16.

CENTRIFUGAL

SWITCH

FIGURE

17.

SETTING

STOP

SCREW

21

Loading...

Loading...