MAINTENANCE

SCHEDULE

Use this factoiy recommended maintenance

(based

on

favorable operating conditions) to

serve

as a guide to

get long and

efficient

set

life.

Neglecting routine main-

tenance

can result in failure or permanent

damage

to the

set. Maintenance is

divided

into two categories: (1) OPER-

ATOR MAINTENANCE

- performed by the operator and

(2) CRITICAL MAINTENANCE

- performed by

qualified

service personnel.

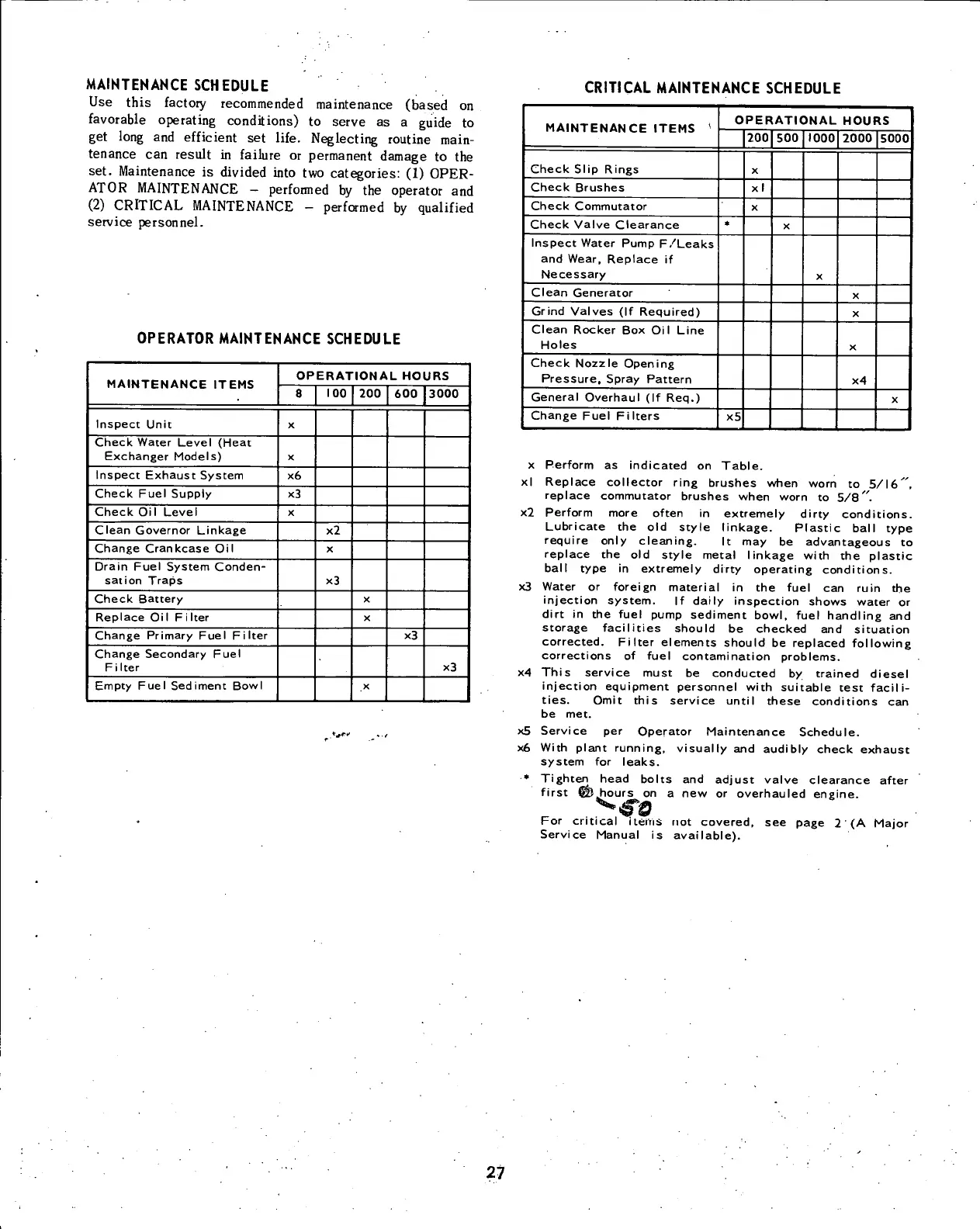

CRITICAL

MAINTENANCE

SCHEDULE

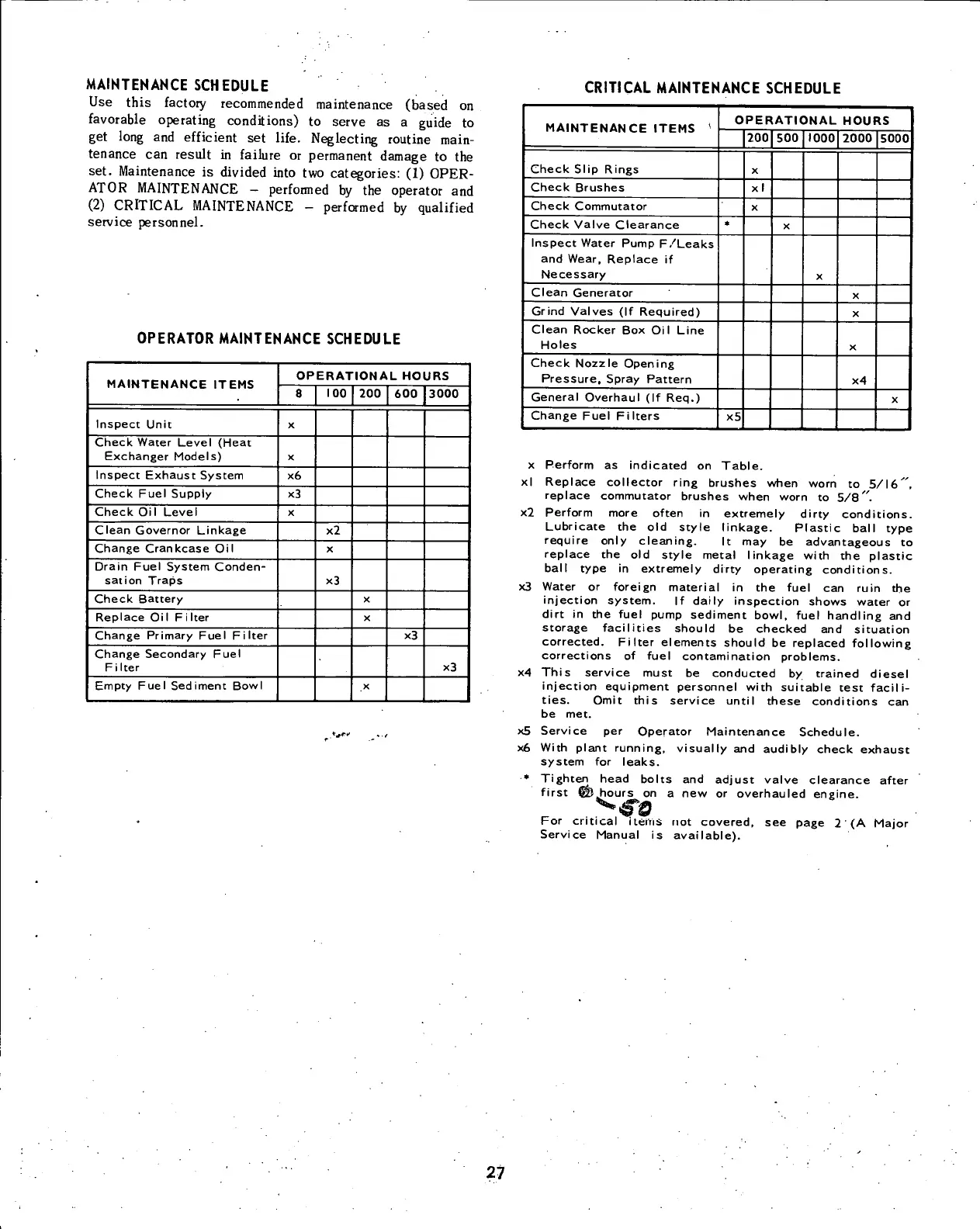

OPERATOR

MAINTENANCE

SCHEDULE

MAINTENANCE ITEMS

OPERATIONAL

HOURS

MAINTENANCE ITEMS

8 100 200

600 3000

Inspect Unit

X

Check Water Level (Heat

Exchanger Models)

X

Inspect Exhaust System

x6

Check Fuel Supply

x3

Check

Oil

Level

X

Clean Governor Linkage

x2

Change Crankcase

Oil

X

Drain Fuel System Conden-

sation Traps

x3

Check Battery

X

Replace

Oil

Filter

X

Change Primary Fuel Filter

x3

Change Secondary Fuel

Filter

x3

Empty Fuel Sediment Bowl

X

MAINTENANCE ITEMS

*

OPERATIONAL

HOURS

MAINTENANCE ITEMS

*

200 500

1000 2000

5000

Check Slip Rings

X

Check Brushes

xl

Check Commutator

X

Check Valve Clearance

*

X

Inspect Water Pump F/Leaks

and Wear, Replace

if

Necessary

X

Clean Generator

X

Grind Valves

(If

Required)

X

Clean Rocker

Box Oil

Line

Holes

X

Check Nozzle Opening

Pressure, Spray Pattern

x4

General Overhaul

(If Req.)

X

Change Fuel Filters

x5

x

Perform as indicated on Table.

xl

Replace

collector

ring

brushes

when

worn

to 5/16",

replace commutator

brushes

when

worn

to 5/8".

x2

Perform more often in extremely

dirty

conditions.

Lubricate

the old style linkage. Plastic

ball

type

require

only

cleaning. It may be

advantageous

to

replace the old style metal linkage

with

the plastic

ball

type in extremely

dirty

operating conditions.

x3 Water or foreign material in the

fuel

can

ruin

the

injection

system. If

daily

inspection shows water or

dirt

in the

fuel

pump sediment

bowl, fuel

handling and

storage

facilities

should be checked and situation

corrected.

Filter

elements

should be replaced

following

corrections of

fuel

contamination problems.

x4

This service must be conducted by trained diesel

injection

equipment personnel

with

suitable

test

facili-

ties.

Omit

this service

until

these

conditions can

be met.

x5 Service per Operator Maintenance Schedule.

x6 With

plant running,

visually

and audibly check

exhaust

system for leaks.

*

Tighten

head

bolts and adjust valve

clearance

after

first

© hours on a new or overhauled engine.

>«

For

critical

items not covered, see

page

2' (A

Major

Service Manual is available).

27

Loading...

Loading...