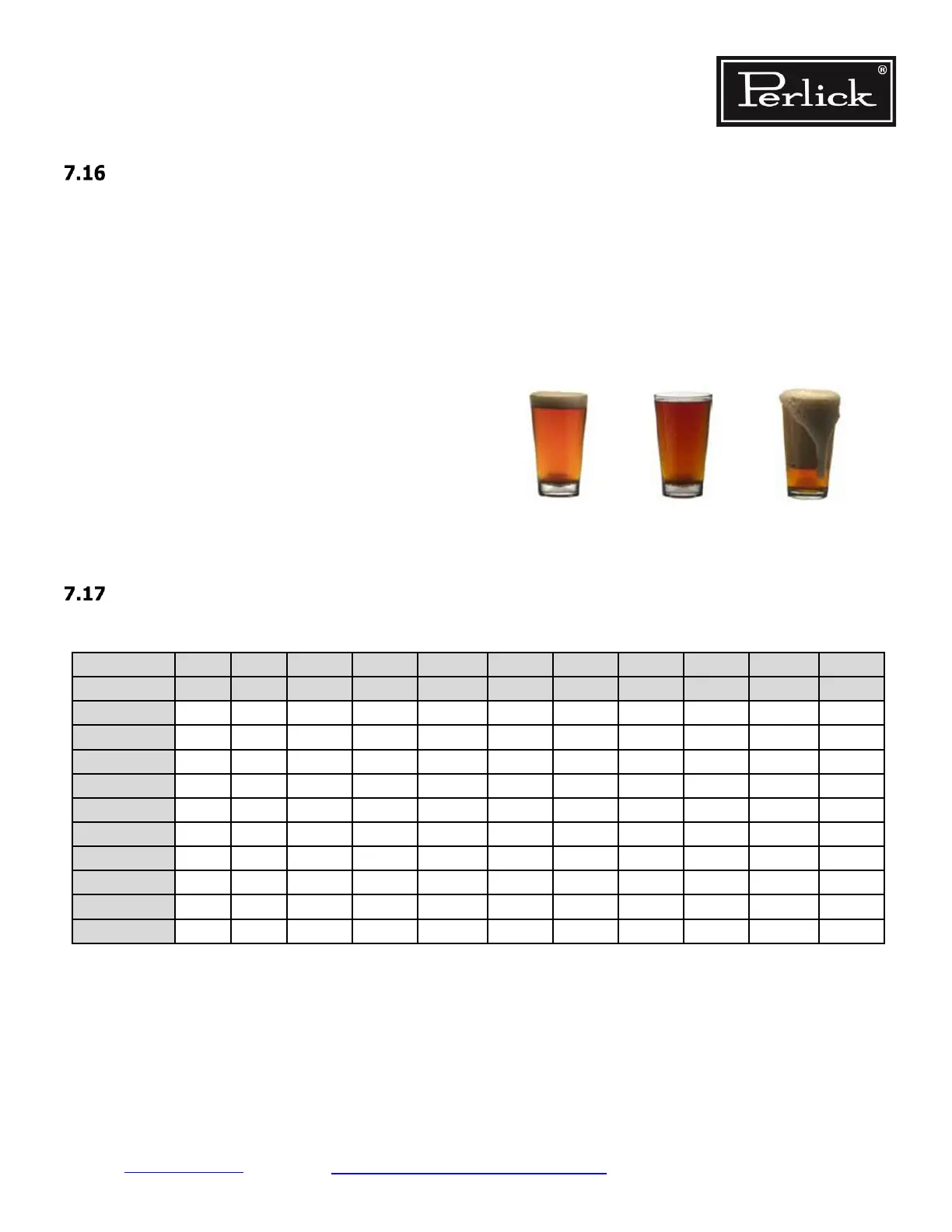

Vol. CO2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1

Temp. °F psi psi psi psi psi psi psi psi psi psi psi

33 5.0 6.0 6.9 7.9 8.8 9.8 10.7 11.7 12.6 13.6 14.5

34 5.2 6.2 7.2 8.1 9.1 10.1 11.1 12.0 13.0 14.0 15.0

35 5.6 6.6 7.6 8.6 9.7 10.7 11.7 12.7 13.7 14.8 15.8

36 6.1 7.1 8.2 9.2 10.2 11.3 12.3 13.4 14.4 15.5 16.5

37 6.6 7.6 8.7 9.8 10.8 11.9 12.9 14.0 15.1 16.1 17.2

38 7.0 8.1 9.2 10.3 11.3 12.4 13.5 14.5 15.6 16.7 17.8

39 7.6 8.7 9.8 10.8 11.9 13.0 14.1 15.2 16.3 17.4 18.5

40 8.0 9.1 10.2 11.3 12.4 13.5 14.6 15.7 16.8 17.9 19.0

41 8.3 9.4 10.6 11.7 12.8 13.9 15.1 16.2 17.3 18.4 19.5

42 8.8 9.9 11.0 12.2 13.3 14.4 15.6 16.7 17.8 19.0 20.1

Return to Table of Contents

Perfect

Carbonation

Under

Carbonation

Over

Carbonation

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Beverage Dispensing

Perfectly poured draught beer is the result of

proper temperature, gas pressure, mixture, and

a well-maintained draught beer system. It’s easy

to take all the variables for granted when beer

is pouring well. But improperly pouring beer

can be very frustrating, and can result in loss of

sales- This chapter is intended to provide useful

troubleshooting steps anyone can follow to solve

draught beer dispense problems.

The single most common cause of problems

encountered in draught beer dispense systems

is temperature control. The rst step in solving

any dispensing problem is to conrm that the

temperature of the keg and the cooler are where

they are supposed to be. In air-cooled and

glycol-cooled systems, the next step is to check

the temperature of the beer being delivered to

the faucet, conrming that the air and glycol

systems

used to maintain proper beer line temperature are

working properly.

The troubleshooting steps that follow are

organized by the type of draught beer system and

how the systems are cooled, using air. Direct-draw

systems cooled by air or glycol each have unique

features that are addressed in the troubleshooting

steps

Other steps including gas pressure and supply,

beer supply, and mechanical issues are also

discussed.

C02 gauge pressure, temperature and carbonation level reference chart

Table 7-3. C02 equilibrium pressure given volumes of C02 and temperature

Based on Data from “Methods of Analysis,’ American Society of Brewing Chemists, 5th Edion – 1949

• The values in this table assume sea-level altitude, beer specic gravity of 1015, and beer alcohol

content at 3.8% abw or 4.8% abv. Values shown are in psig or gauge pressure.

• It’s important to remember that carbonation is proportional to absolute pressure, not gauge pres

-

sure. Atmospheric pressure drops as elevation goes up. Therefore, the gauge pressure needed to

achieve proper carbonation at elevations above sea level must be increased. Add 1 psi for every

2,000 feet above sea level. For example, a retailer at sea level would use 11.3 psi gauge pressure to

Refrigeration System Repair Instructions Page 7-12

Loading...

Loading...