11.INSTALLATION TOOLS AND INSTALLATION FLOW CHART

11. Installation tools and installation flow chart

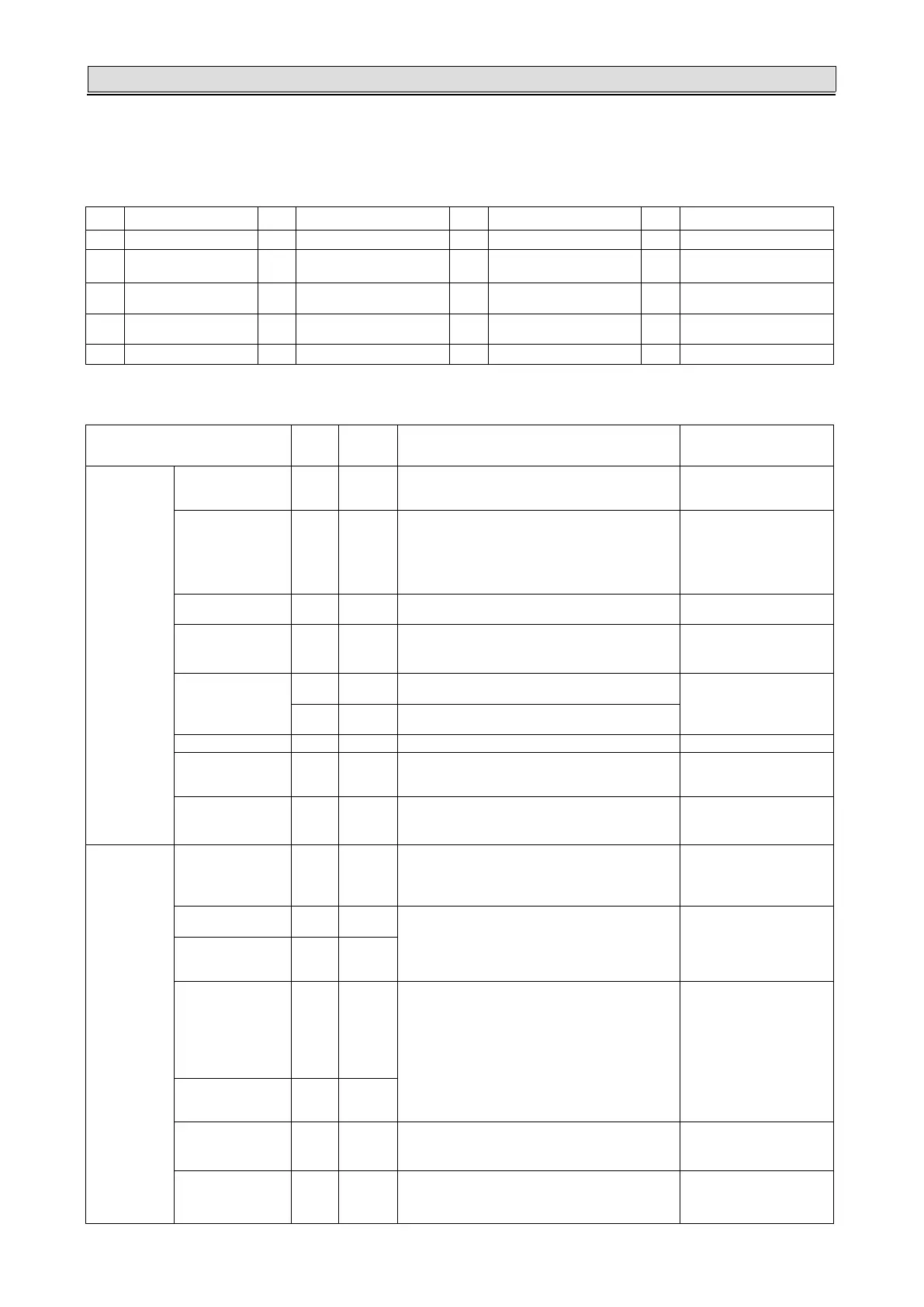

11.1 Necessary tools and instrument list for installation

Necessary Tools and Instrument List for Installation

No. Tool No. Tool No. Tool No. Tool

1

Handsaw

6

Copper Pipe Bender 11 Spanner 16 Leveler

2

Phillips Screwdriver

7

Manual Water Pump

12

Charging Cylinder

17

Clamper for Solder-

less Terminals

3

Vacuum Pump

8

Pipe Cutter 13 Gauge Manifold 18

Hoist

(for Indoor Unit)

4

Refrigerant

Gas

Hose

9

Brazing Kit 14 Cutter for Wires 19 Ammeter

5

Megohmmeter 10 Hexagon Wrench 15 Gas Leak Detector 20 Voltage Meter

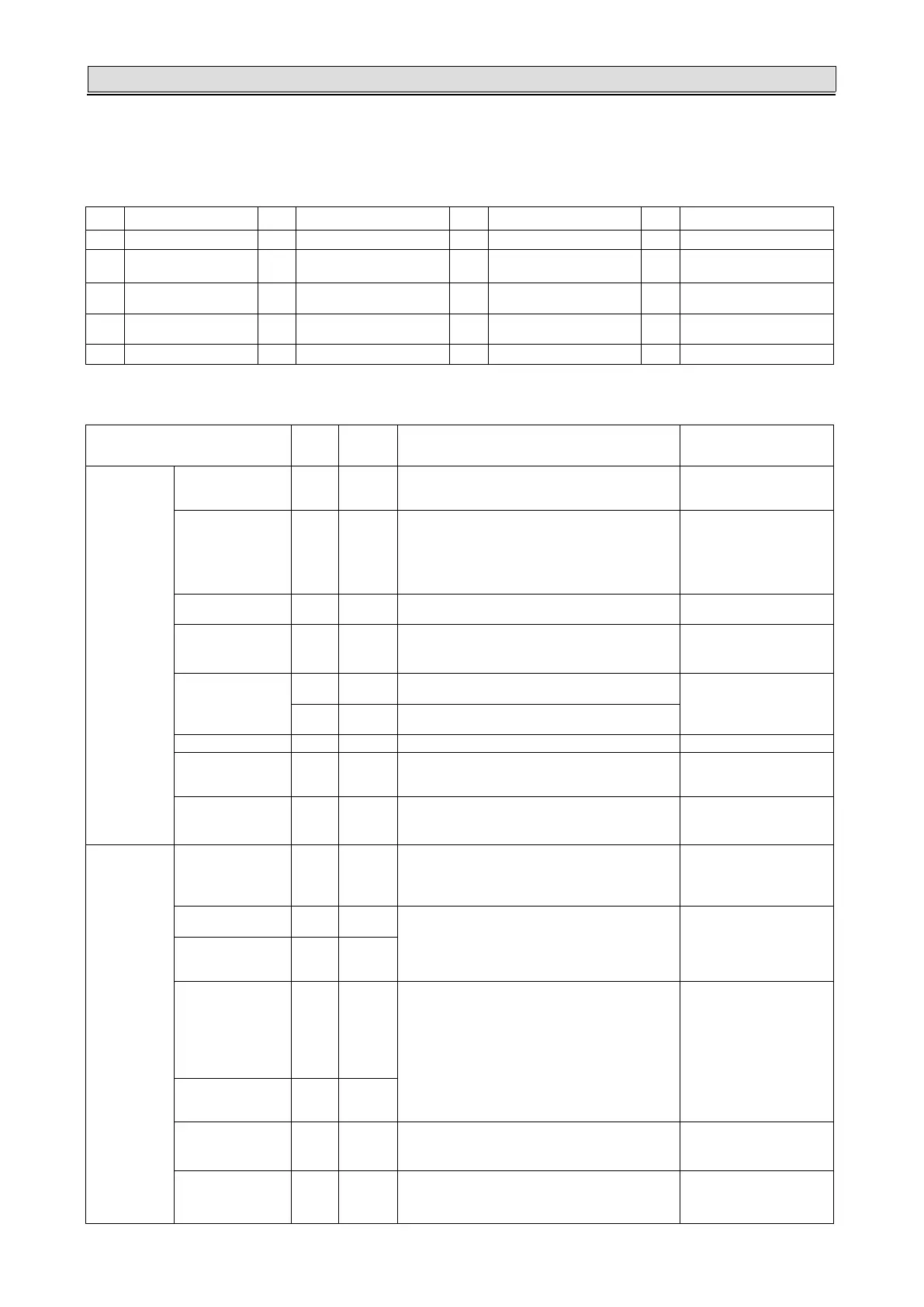

Use tools and measuring instruments only for the new refrigerant which is direct contact with to refrigerant.

✧ : Interchangeability is available with R410A ●: Only for Refrigerant R32

✕ : Prohibited ✦ : Only for Refrigerant R22

Measuring Instrument and

Tool for R410A

R32 R22

Reason of Non-Interchangeability

and Attention (*: Strictly Required)

Use

Refrigerant

Pipe

Pipe Cutter

Chamfering

Reamer

✧ ✧ -

Cutting Pipe Removing

Burrs

Flaring Tool ✧ ✧

* The flaring tools for R32 are applicable to

R22/R410A.

* If using flaring tube, make dimension of

tube larger for R410A.

* In case of material 1/2H, flaring is not

available.

Flaring for Tubes

Pipe Bender ✧ ✧

* In case of material 1/2H, bending is not

available. Use elbow for bend and braze.

Bending

Expanding Tool ✧ ✧

* In case of material 1/2H, expanding of tube

is not available. Use socket for connecting

tube.

Expanding Tubes

Torque Wrench

✧ ×✕ * For φ1/2, φ5/8, spanner size is up 2mm.

Connection of Flare Nut

✧ ✧

* Forφ1/4, φ3/8, φ3/4, spanner size is the

same.

Brazing Tool ✧ ✧ * Perform correct brazing work. Brazing for Tubes

Nitrogen Gas ✧ ✧

* Strict Control against Contamin (Blow

nitrogen during brazing.)

Prevention from

Oxidation during

Brazing

Lubrication Oil

(for Flare

Surface)

● ✦

* Use a synthetic oil which is equivalent to

the oil used in the refrigeration cycle.

* Synthetic oil absorbs moisture quickly.

Applying Oil to the

Flared Surface

Vacuum

Drying&

Refrigerant

Charge

Refrigerant

Cylinder

✕ ✕

* Check refrigerant cylinder color.

* Liquid refrigerant charging is required

regarding zeotoropic refrigerant.

* Use the weight scale.

Refrigerant Charging

Vacuum Pump ✧ ✧

* The current ones are applicable. However,

it is required to mount a vacuum pump

adapter which can prevent from reverse flow

when a vacuum pump stops, resulting in no

reverse oil flow.

Vacuum Pumping

Adapter for

Vacuum Pump

✧ ✦

Manifold Valve ✧ ✦

* No interchangeability is available due to

higher pressures when compared with R22.

* Do not use current ones to the different

refrigerant. If used, mineral oil will flow into

the cycle and cause sludges, resulting in

clogging or compressor failure.

* Connection diameter is different;

R32/R410A: UNF1/2, R22: UNF7/16.

Vacuum Pumping,

Vacuum Holding,

Refrigerant Charging

and Check of Pressures

Charging Hose ✧ ✕

Weight Scale ✧ ✧

Measuring Instrument

for Refrigerant

Charging

Refrigerant Gas

Leakage

Detector

✕ ✕

* The current gas leakage detector (R22) is

not applicable due to different detecting

method.

Gas Leakage Check

Loading...

Loading...