19PM-1440BV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

Section 4 SERVICING THE LATHE

Disconnect 220V power before any maintenance operation!

Remove all machining debris and foreign objects before lubricating ANYTHING! If need

be, any oil is better than no oil – but use the recommended lubricants when you can.

HEADSTOCK GEARBOX DRAIN & REFILL

Take time to prepare. 4 quarts is a lot of oil to clean up!

1. Run the lathe a few minutes to warm the oil if necessary.

2. Open the drive train cover left of the headstock.

3. Remove the ll plug on the top surface of the headstock,

GENERAL

Aside from abrasive particles and machining debris, lack of

proper lubrication is the main cause of premature wear. Ro-

tating parts are easy to lubricate, sliding parts are not. Gibs

are tightened for the best compromise between rigidity and

slideability, which means practically zero gap between the

ways. It is not obvious which are the bearing surfaces on the

various dovetail surfaces — some of the interfaces look like

bearing surfaces, but are simply narrow gaps.

Every few hours of operation: 1. Apply the recommended way-

oil with a dedicated short-bristle brush such as the type used

for applying ux; 2. Use a similar brush to apply oil or grease to

the leadscrews; 3. Apply oil to the ball oilers, see below.

The spindle runs on sealed, pre-lubricated roller bearings re-

quiring no routine attention.

Recommended lubricants

Gearboxes: ISO 68, such as Mobil DTE Heavy/Medium circu-

lating oil. Approximate quantities required:

Headstock 4 quarts

Saddle feed gearbox 2 quarts

Apron 1 quart

Ball oilers: ISO 68 way oil, such as Mobil Vactra No. 2, or

equivalent.

Machine ways (dovetails): ISO 68 way oil, such as Mobil

Vactra No. 2, or equivalent.

External change gears: light general purpose grease, NLGI

No. 2, or equivalent.

Leadscrews: ISO 68 way oil, such as Mobil Vactra No. 2, or

equivalent.

BALL OILERS

Use a pump-type oil can, preferably with a exible spout tipped

with a soft tube. The ID of the tip should be large enough

to seat on the oiler's brass ange, more than spanning the

spring-loaded steel ball. When the oil can tip is rmly pressed

onto the brass surface oil pressure will displace the ball, allow-

ing oil to ow into the bearing. Before oiling check that the ball

is not stuck – press it lightly with a probe.

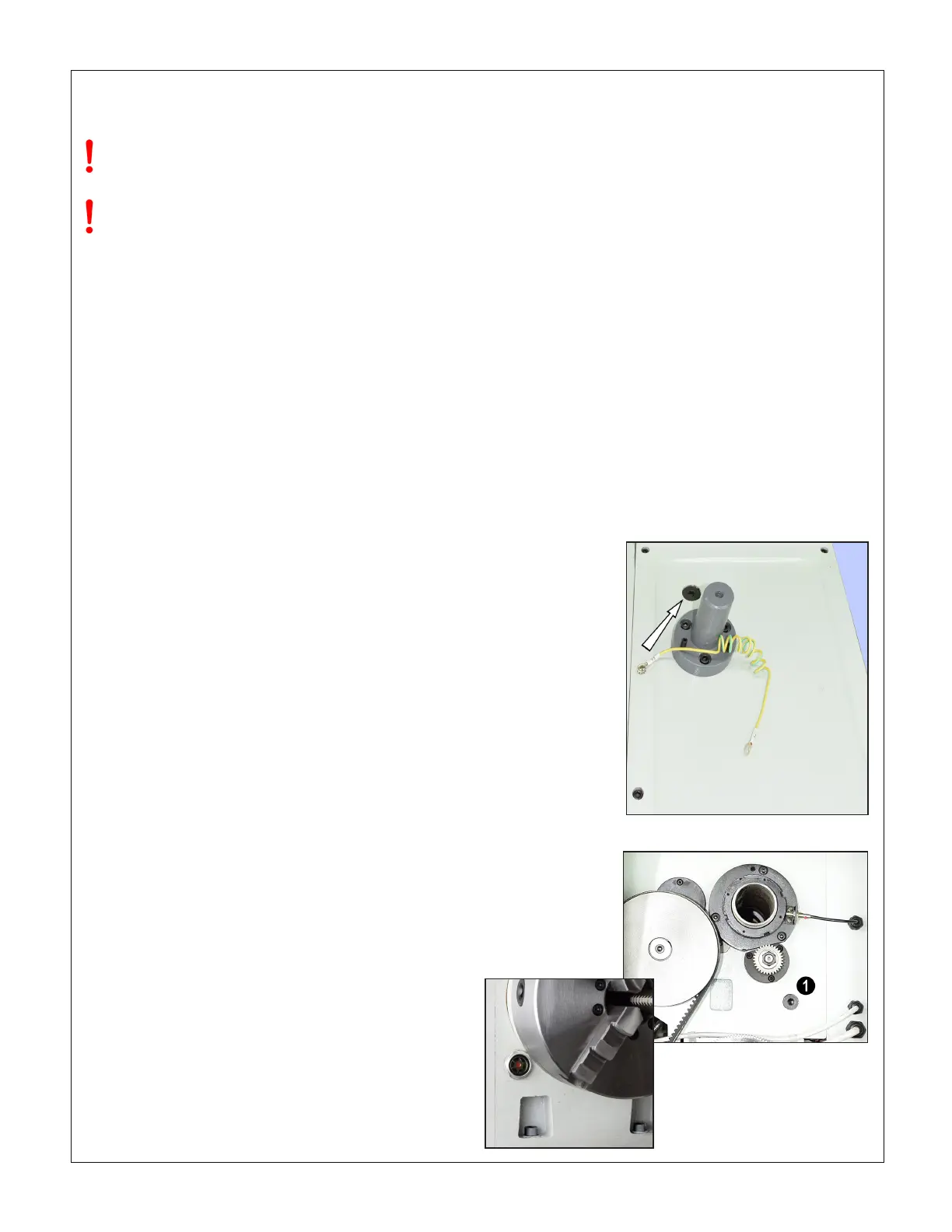

Figure 4-1.

4. Place a drain pan (2-gallons minimum) on a stool or other

support at about the height of the chip tray.

5. Fold a sheet of card stock to make a Vee-shape drain

channel. This will be pressed against the headstock below

the drain plug, angled downward into the drain pan; trim

the upstream end of the Vee so that it seals against the

headstock.

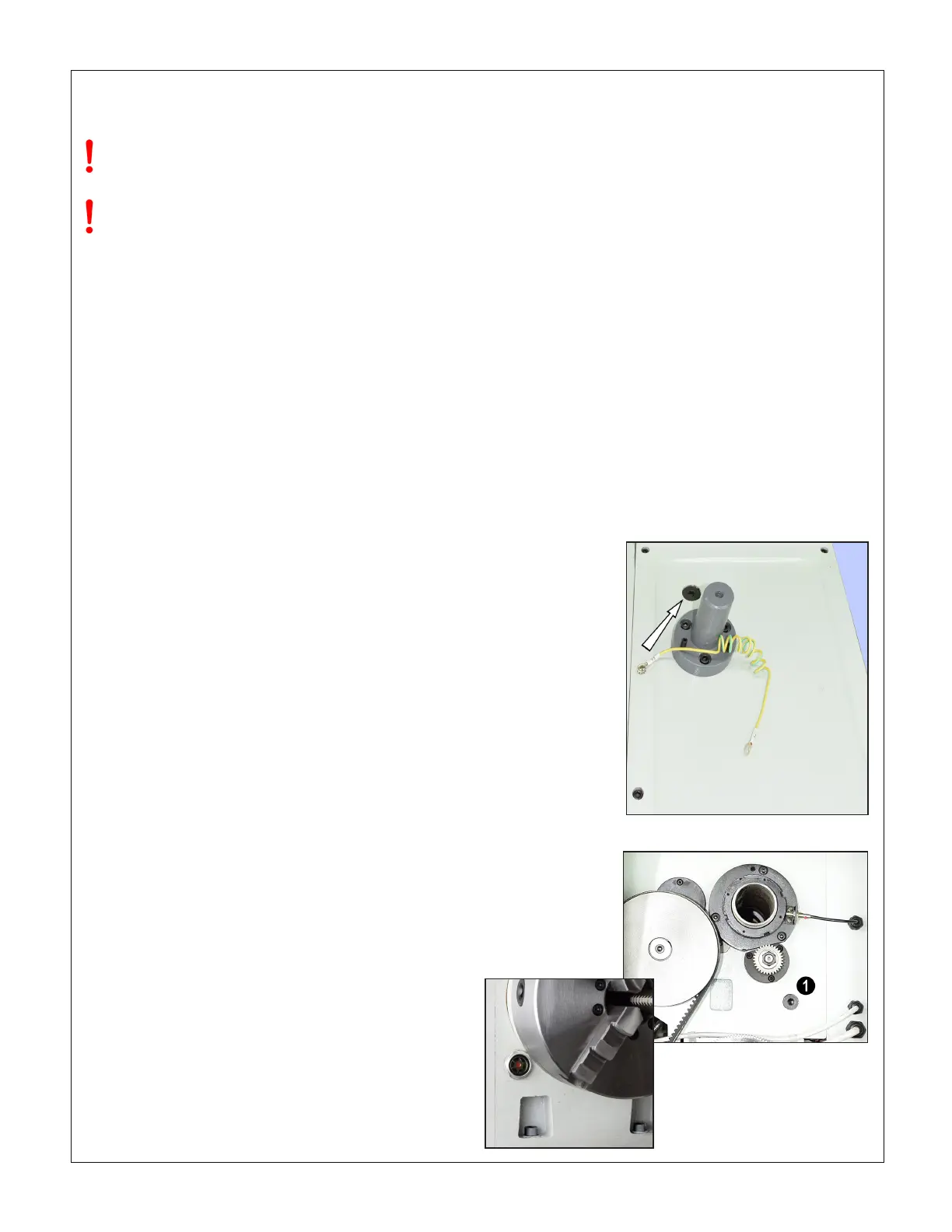

6. With the drain channel in place, remove the drain plug, Fig-

ure 4-2.

7. Allow the oil to drain completely. Replace the drain plug,

then add just a few ounces of oil.

8. When satised that the headstock is oil-tight, add oil to the

halfway mark on the sight glass, Figure 4-3 (about 4 qts).

9. Replace the ll plug.

Figure 4-1 Headsto

Figure 4-3 Headstock sight glass

Figure 4-2 Headstock

drain plug (1)

Loading...

Loading...