4PM-1440BV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

COOLANT TANK

Inspect the coolant tank and pump assembly in the RH cabi-

net, Figure 1-4. The tank may have become dislodged in ship-

ment. Level it if necessary. Check that the footbrake spindle is

not pressing on the side of the tank. Reposition the spindle if

necessary.

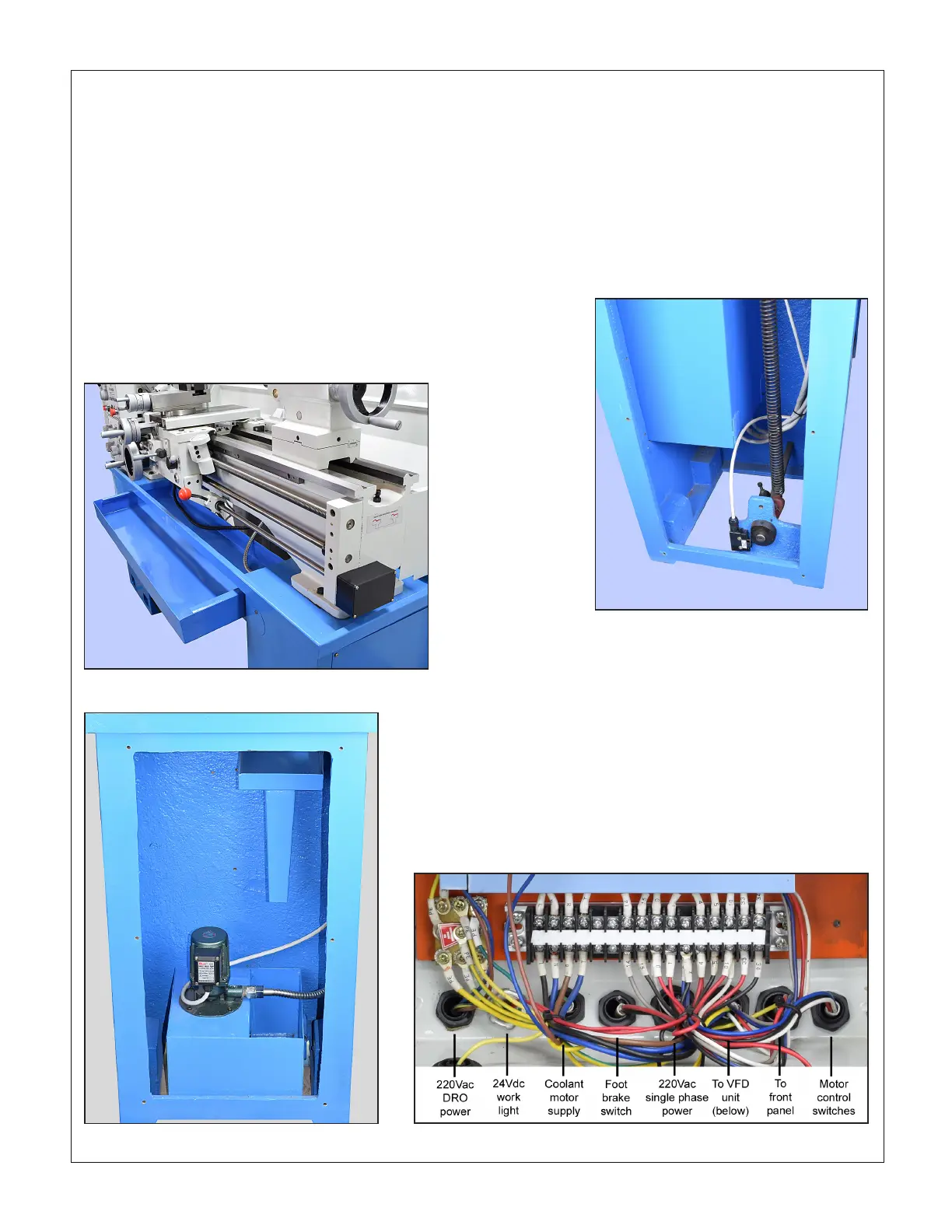

Figure 1-3 Chip tray

Figure 1-4 Coolant tank

CLEANUP

Metal surfaces may have been protected by thick grease and/

or paper. Carefully remove these using a plastic paint scraper,

disposable rags and a light-oil such as WD-40.

available. If not, use the most reliable level on hand. Check and

adjust level front-to-back across the bed using a matched pair

of spacer blocks to clear the Vee tenons on the bed ways. The

blocks need to be at least 1/4 inch thick, ground or otherwise

accurately dimensioned. Alternatively, check for level on the

ground surface of the cross slide as the carriage is traversed

from end to end. See also "Aligning the Lathe" in Section 4.

FOOTBRAKE INTERLOCK

The lathe will not run if the footbrake switch fails to close when

the foot treadle is released (brake OFF). This switch is locat-

ed inside the LH stand cabinet. Check that the D-shape cam

operates the switch when the treadle is pressed, Figure 1-5.

CHIP TRAY

Check that the chip tray, Figure 1-3, can be pulled forward

without snagging coolant hoses and worklight wiring. Use ca-

ble ties if necessary.

Figure 1-5 Footbrake switch

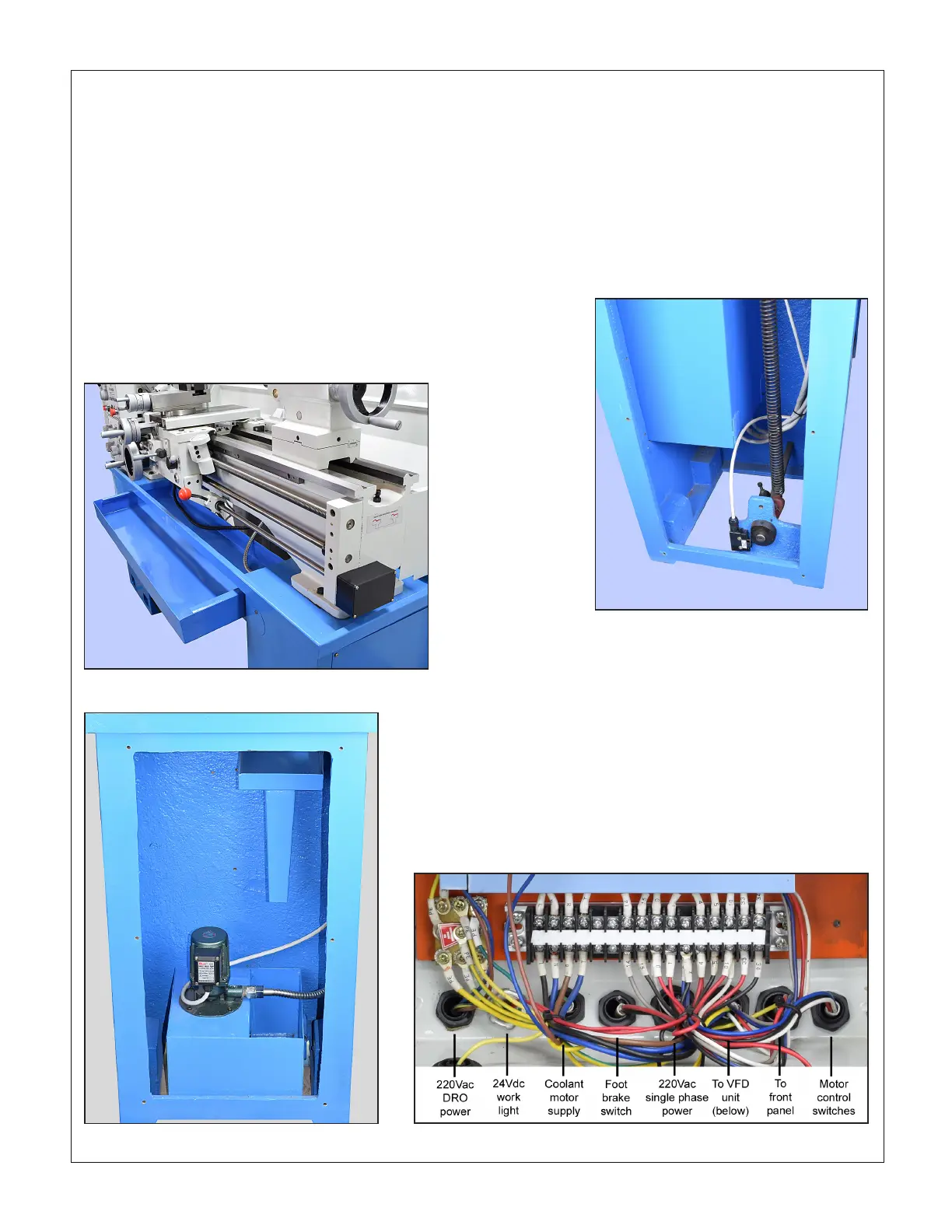

ELECTRICAL CONNECTIONS

As shipped, the PM-1440BV is set for 220 Vac single phase

power.

Read Initial Checks, below, before connecting power

Remove the upper rear cover from the LH cabinet. If the lathe

did not come with a pre-installed power cord, connect the pow-

er source through a strain relief bushing to the port shown in

Figure 1-6 using 12 AWG (minimum) 3-wire cord. The 220V

input is identied as L, N at left of the connector strip.

Figure 1-6 Connections to upper electrical box

Loading...

Loading...