10

PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC

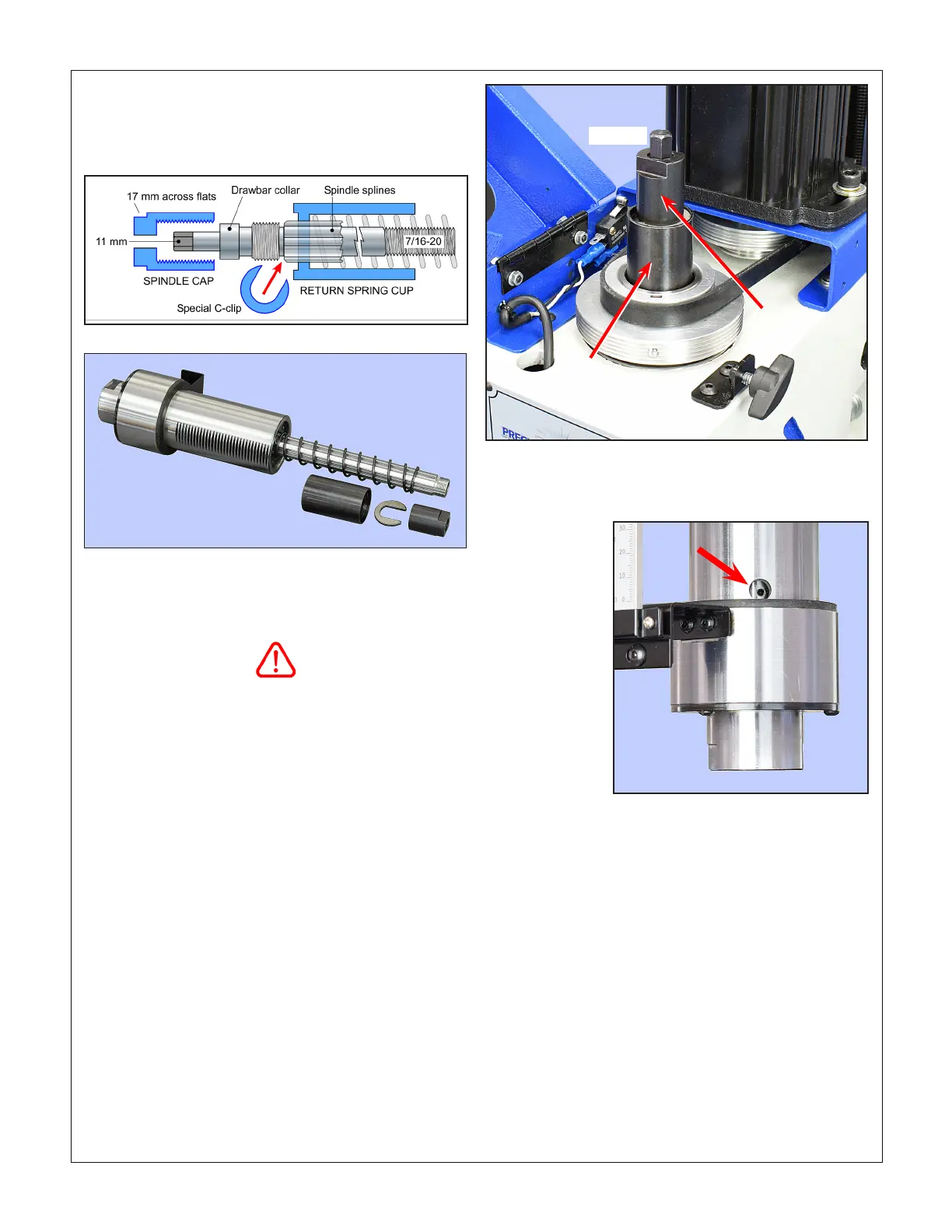

Two tools are required to install or remove R8 tooling: an 11 mm

wrench for the square drawbar nut, and the supplied C-wrench

which engages in ats at the bottom end of the spindle.

Figure 3-5 Two-step belt drive

The drawbar collar, Figure 3-2, must be

UNDER the spindle cap, as shown

Removing R8 tooling

Protect the table, vise or workpiece under the spindle with rags

or scrap wood. Why? Because they can easily be damaged by

falling tools and drill chucks. The cutting tool itself can also be

damaged in the same way.

Lock the spindle with the C-wrench, loosen the drawbar one

turn or less, just enough to unseat the taper, then tap the top

of the drawbar with a brass or dead-blow hammer to break the

taper seal. Unscrew the drawbar with one hand while support-

ing the R-8 device with the other hand.

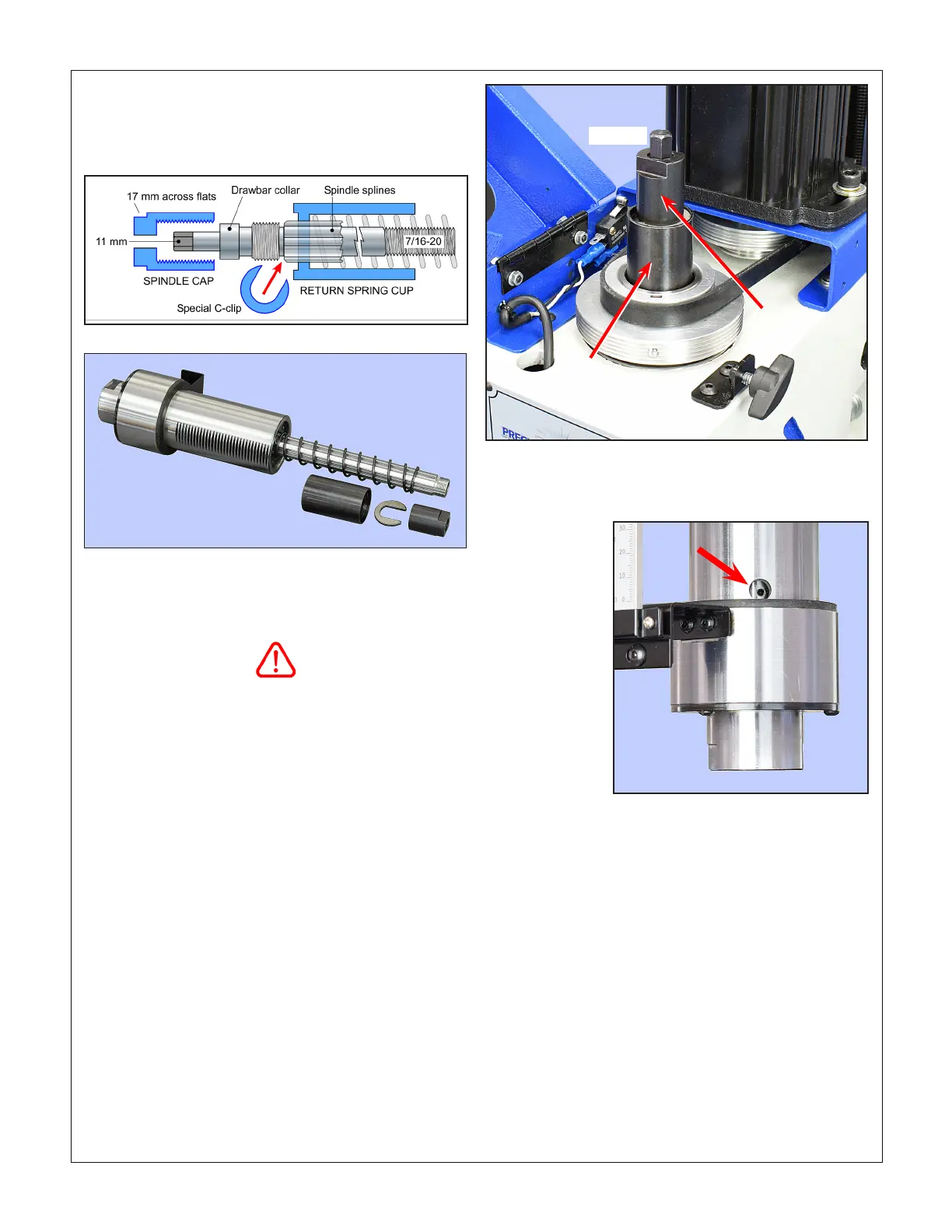

R8 tooling is located in the spindle bore by an M4 x 6 mm

long set screw. If it is dicult or impossible to insert the

R8 device, chances are the set screw is in too far. Rotate

the spindle by hand to expose the screw, Figure 3-6, then

back it out a fraction of a turn using a 2 mm hex wrench.

Hand rotate the spindle again to check that the screw

clears the inside surface of the quill.

INSTALLING AND REMOVING TOOLING

The spindle and drawbar are designed for R-8 taper collets,

drill chucks and other arbors with the standard 7/16”-20 inter-

nal thread.

Figure 3-4 Spindle disassembled (drawbar omitted)

Figure 3-3 Spindle schematic

Return

spring

cup

Spindle

cap

Drawbar

Figure 3-6 Collet set screw

Installing R8 tooling

Install the R-8 device, then hand-thread the drawbar into it until

the drawbar collar bottoms on the splined spindle (on the ma-

chine itself this action is concealed by the spindle cap, Figure

3-3). Fully tighten the drawbar with an 11 mm wrench, while at

the same time holding the spindle stationary with the special

C-wrench, page 7. [Do NOT try to hold the spindle using the

ats on the spindle cap.]

Loading...

Loading...