11

PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC

MOVING THE TABLE & HEADSTOCK

Conventionally, left-right movement of the table is said to be

along the X-axis (also called “longitudinal travel” or “travers-

ing”). Leadscrew handwheels are provided at both ends of the

table, Figure 3-7. Front-to-back movement is along the Y-axis,

sometimes called “cross travel”. The Y axis leadscrew has a

single handwheel at the front, Figure 3-8.

Headstock motion is in the Z-axis, in line with the vertical col-

umn. The headstock is raised and lowered by a handwheel at

top right of the column, Figure 3-9.

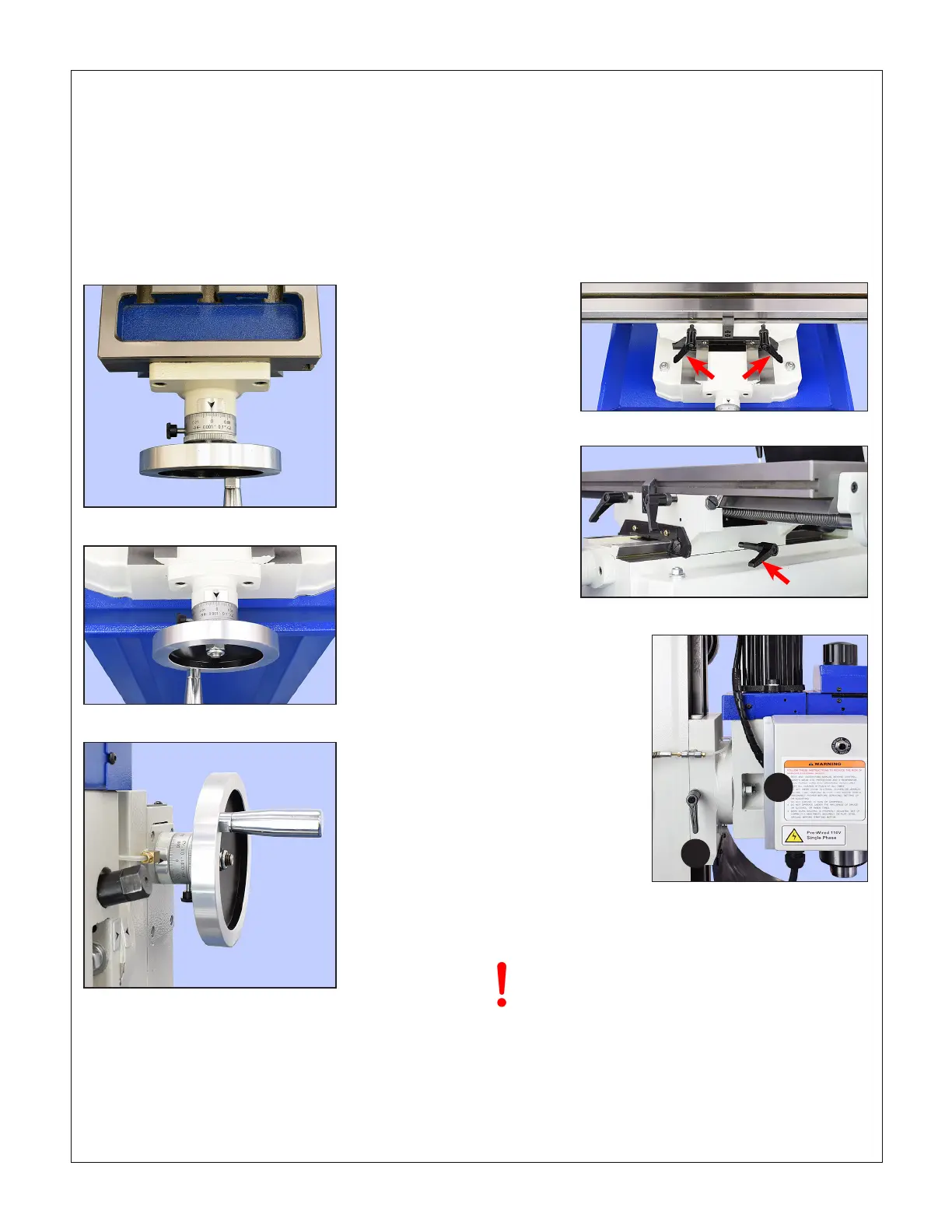

Figure 3-10 X-axis locks

Figure 3-11 Y-axis lock

When possible, operations calling for precise

depth control (such as milling) should be done

with the headstock locked, also with the quill

fully retracted into the headstock and locked.

Figure 3-12 Z-axis lock (1)

Also shown here (2) is one of two headstock attachment nuts.

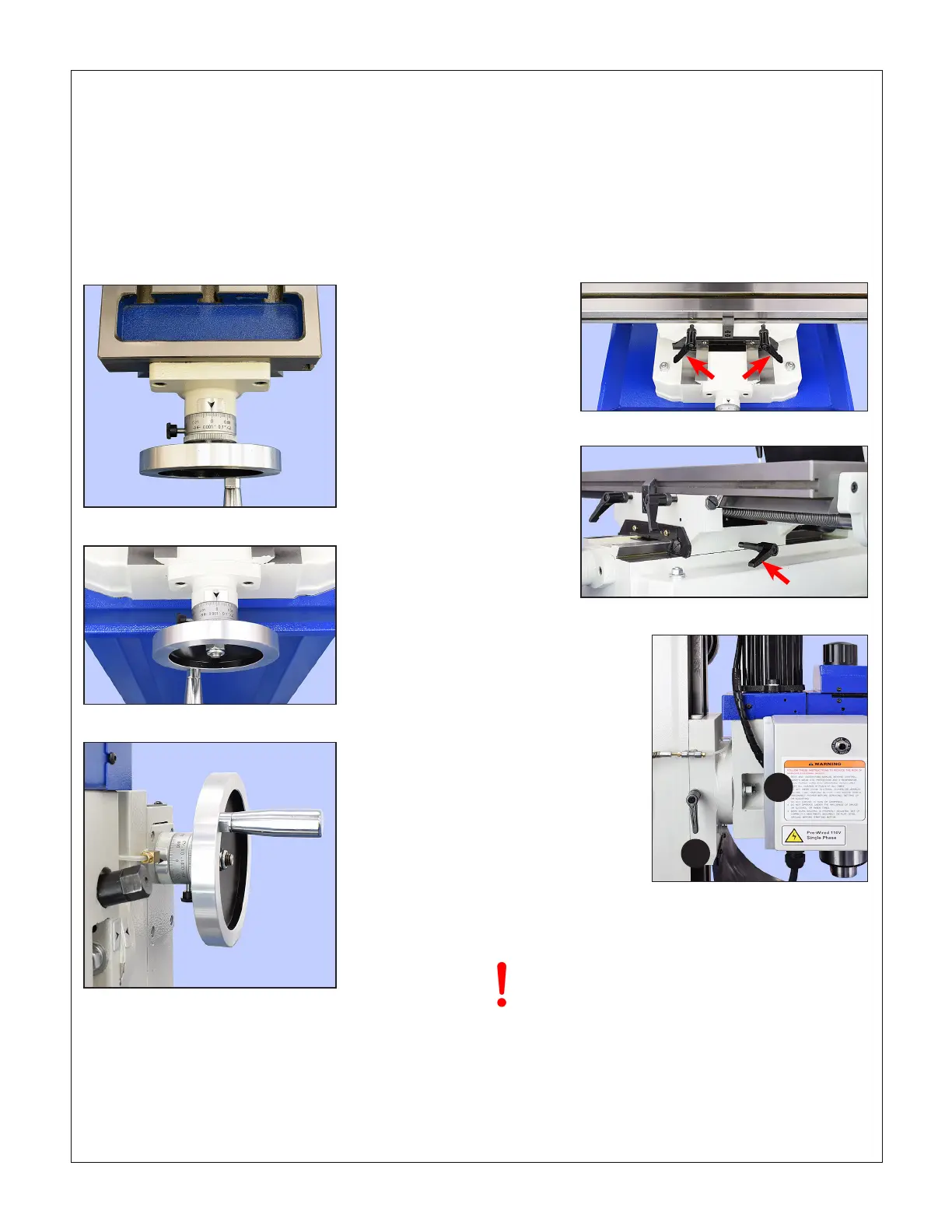

Figure 3-7 X-axis handwheel & dial (right hand)

Figure 3-8 Y-axis handwheel & dial

Figure 3-9 Z-axis handwheel & dial

LOCKING THE AXES

Before machining a workpiece it is usually necessary to po-

sition the table precisely, then lock either the X or the Y axis,

sometimes both (for drilling and similar operations). You can

also use the lock levers to apply a light drag to the axis in

motion. This can help reduce chattering (better surface nish)

and also lessen the chance of overshooting inadvertently. To

reduce wear, free the levers once the operation is completed.

Each axis has a leadscrew with handwheel and graduated dial

with 0.001” divisions, 0.1” per revolution, Figures 3-7 to 3-9.

If the mill is not equipped with digital readouts (DROs), the

table and headstock can be accurately positioned by count-

ing whole turns and divisions, keeping leadscrew backlash

in mind. This means that motion must always be in the same

direction up to the point of reference, then on to the desired

location, see “Positioning by Counting X-Y Divisions”, later in

this section.

2

1

Loading...

Loading...