>----

,. -

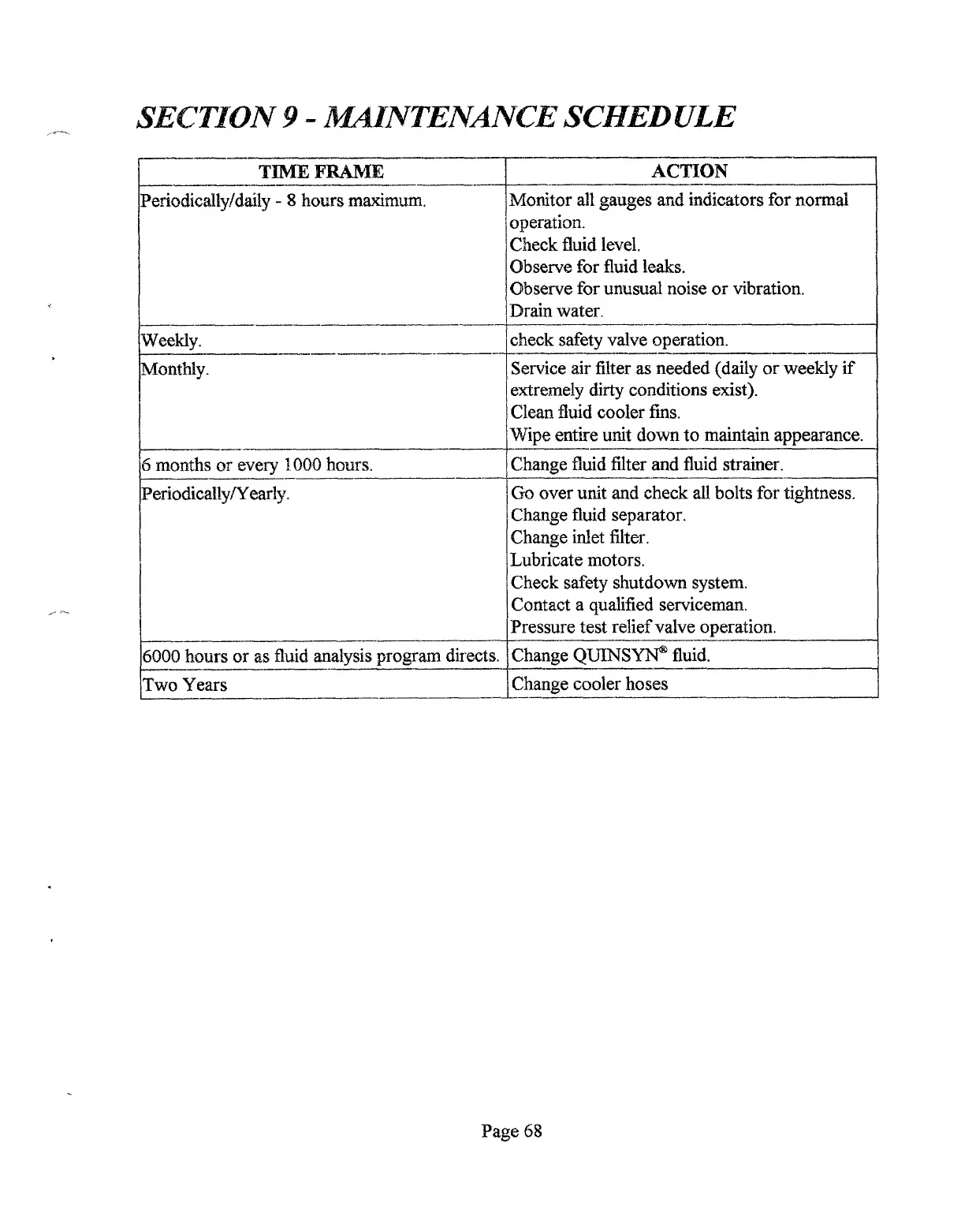

SECTION 9=MAINTENANCE SCHEDULE

TIME FRAME

I

ACTION

‘eriodically/daily - 8 hours rnaximwn,

Monitor all gauges and indicators for normal

operation.

Check fluid level.

Observe for fluid leaks.

Observe for unusual noise or vibration.

Drain water.

Veekly.

1

check safety valve operation.

———.—..——

—-

Aontldy.

%x-vice air filter as needed (daily or weekly if

extremely dirty conditions exist).

Clean fluid cooler fins.

Wipe entire unit down to maintain appearance.

i monthsor every 1000 hours.

——

———

— ..—

~eriodically/Yearly.

Change fluid filter and fluid strainer.

Go over unit and chec~all bolts for ;ightness.

Change fluid separator.

Change inlet filter.

Lubricate motors.

Check safety shutdown system.

Contact a qualified serviceman.

Pressure test relief valve operation.

iOOObcmrs or as fluid analysis program dkects.

Change QUINSYl@ fluid.

——

rwOYears

Change cooler hoses

Page 68

.—.——.—.. — . ..—...—

——.—.—--— .—-—.——..—. —.

—m-.—-. ..— —.—

.—— ——.. —

. . . . . . . . . . . . . .

. .-_-.. . . . . . .

. . . . . . . . . . . . . . . . ._= ___ . _______

Loading...

Loading...