15

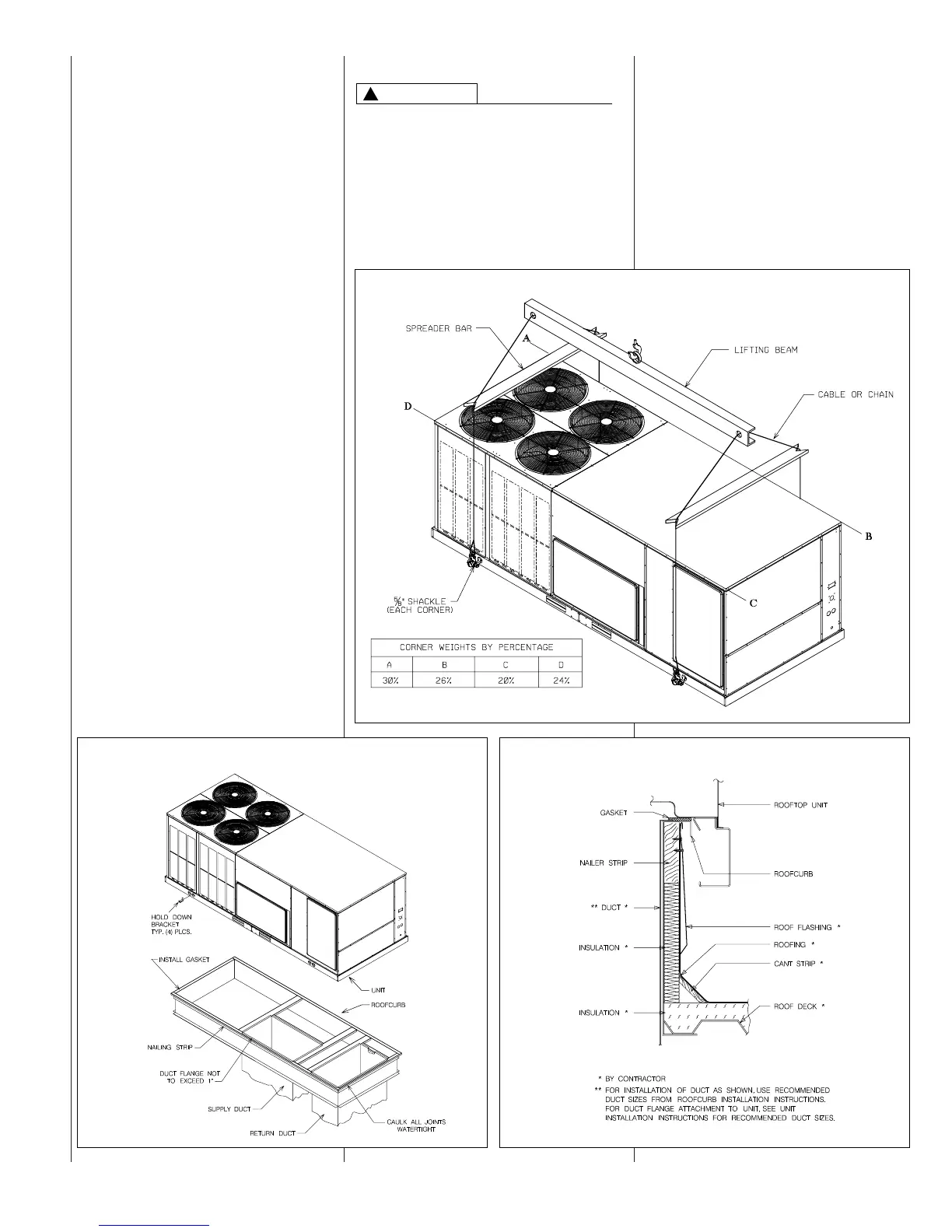

FIGURE 15. ROOFCURB

space as possible allowing clearances

as indicated. Run ducts as directly as

possible to supply and return outlets.

Use of non-flammable weatherproof

flexible connectors on both supply and

return connections at unit to reduce

noise transmission is recommended.

On ductwork exposed to outside

temperature and humidity, use a

minimum of 2” of insulation and a vapor

barrier. Distribution system in attic, furred

space or crawl space should be

insulated with at least 2” of insulation.

1

/2”

to 1” thick insulation is usually sufficient

for ductwork inside the air conditioned

space.

Provide balancing dampers for each

branch duct in the supply system.

Properly support ductwork from the

structure.

IMPORTANT: In the event that the return

air ducts must be run through an

“unconfined” space containing other fuel

burning equipment, it is imperative that

the user/building owner must be

informed against future changes in

construction which might change this to

a “confined space.” Also, caution the

user/building owner against any future

installation of additional equipment (such

as power ventilators, clothes dryers,

etc.), within the existing unconfined

and/or confined space which might

create a negative pressure within the

vicinity of other solid, liquid, or gas fueled

appliances.

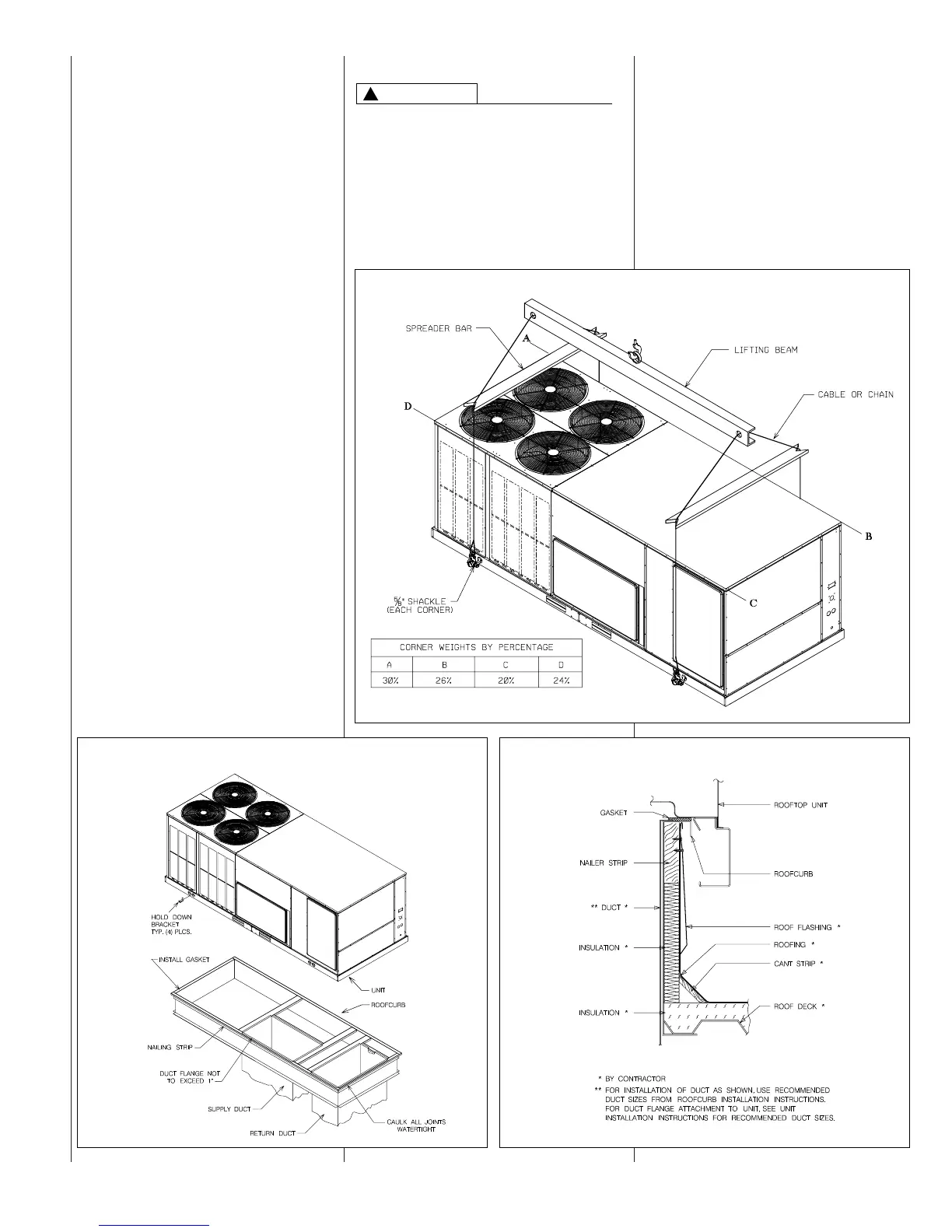

FIGURE 14. LIFTING DETAIL

!

WARNING

RETURN AIR

NEVER ALLOW PRODUCTS OF

COMBUSTION OR THE FLUE

PRODUCTS TO ENTER THE RETURN

AIR DUCTWORK, OR THE

CIRCULATING AIR SUPPLY. ALL

RETURN DUCTWORK MUST BE

ADEQUATELY SEALED AND

SECURED TO THE FURNACE WITH

SHEET METAL SCREWS, AND JOINTS

TAPED. ALL OTHER DUCT JOINTS

MUST BE SECURED WITH APPROVED

CONNECTIONS AND SEALED

AIRTIGHT.

FAILURE TO PREVENT PRODUCTS OF

COMBUSTION FROM BEING

CIRCULATED INTO THE LIVING SPACE

CAN CREATE POTENTIALLY

HAZARDOUS CONDITIONS,

INCLUDING CARBON MONOXIDE

POISONING THAT COULD RESULT IN

PERSONAL INJURY OR DEATH.

ST-A0886-12

ST-A0888-02

ST-A0888-02

FIGURE 16. ROOFCURB

Loading...

Loading...