23

INSTALLATION

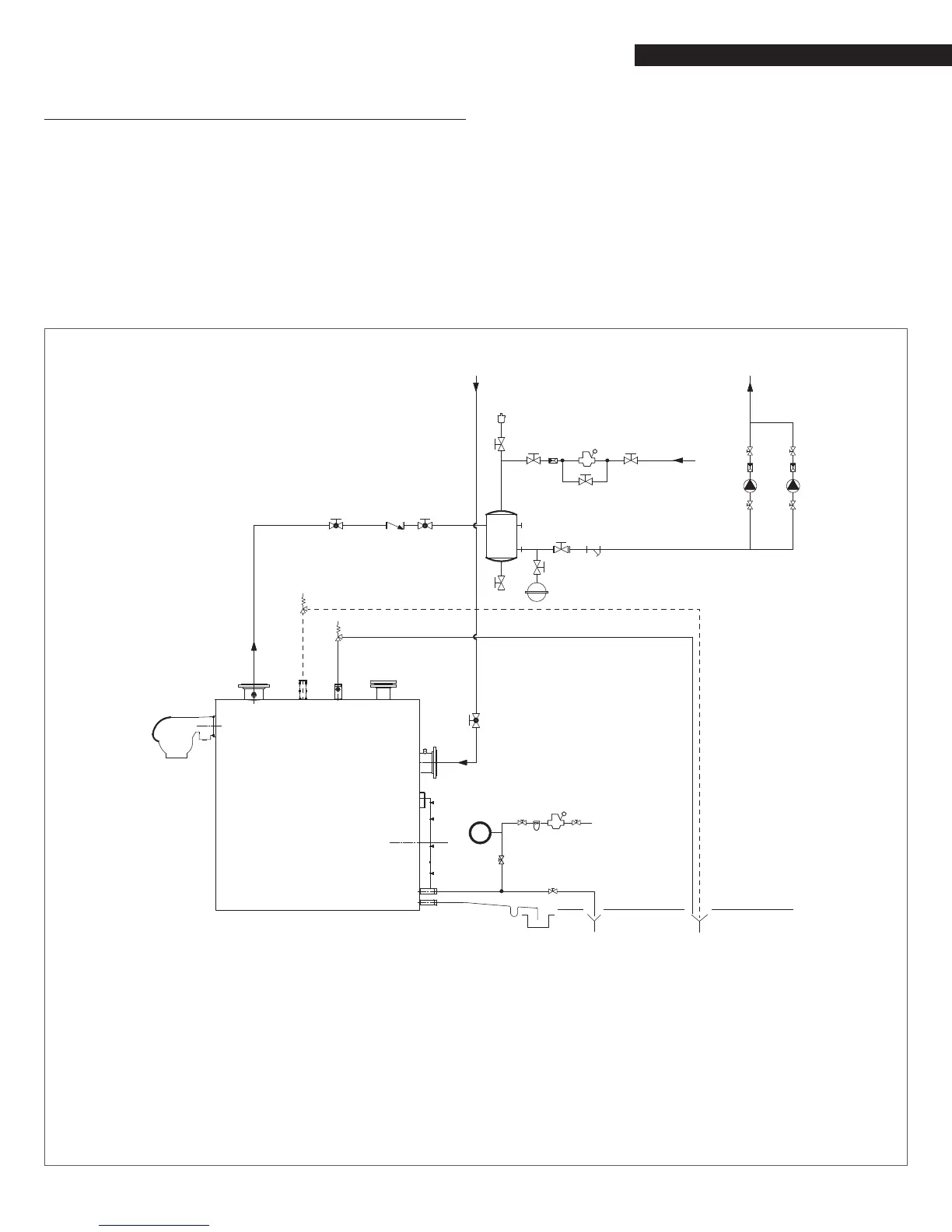

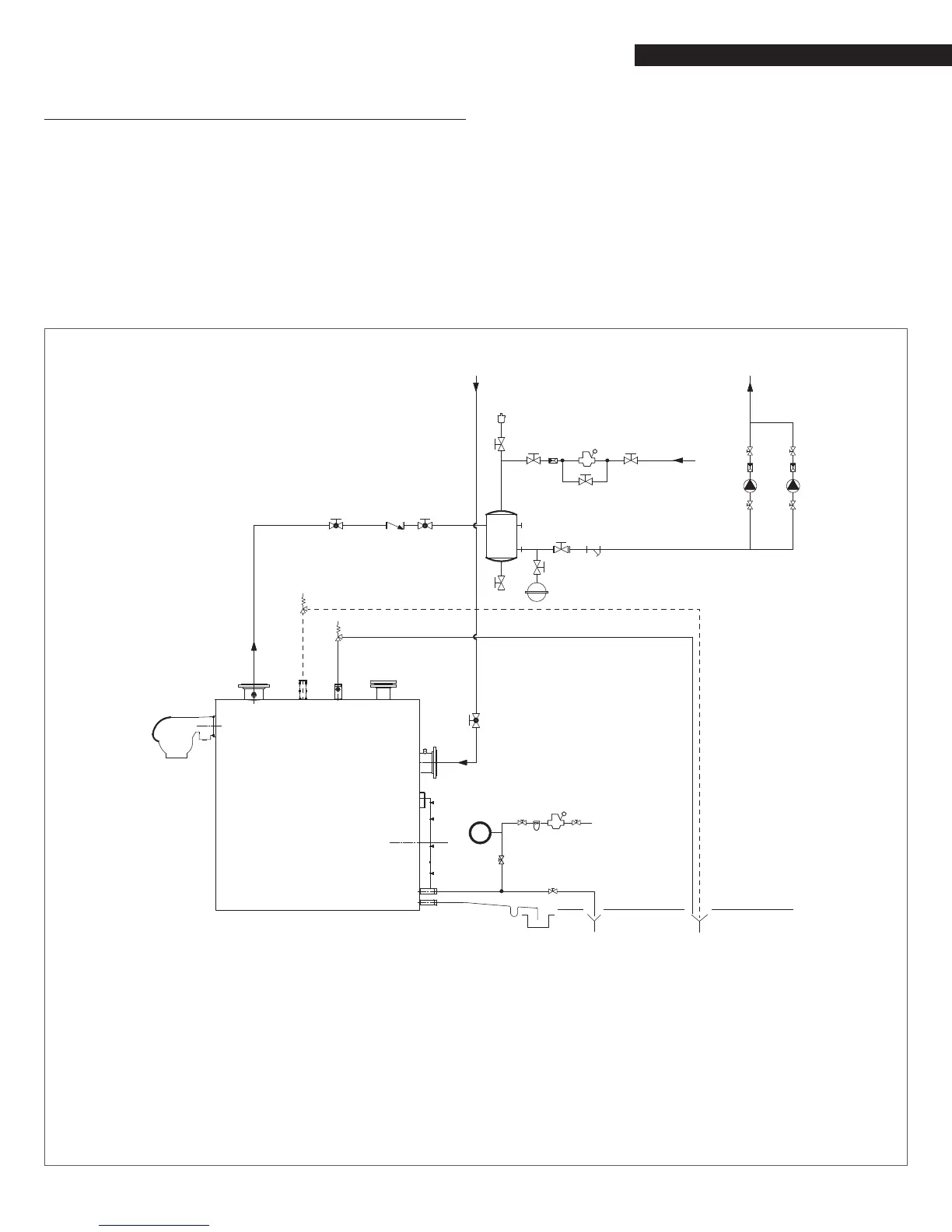

2.7 Typical water system schematics

The following P&ID represent the typical arrangement for the most

common types of installation and they are only a suggestion for

the installer that is resposible for all equipment and details re-

quired by local laws.

9

The DHW and central heating circuits must incorporate ex-

pansion vessels of adequate capacity as well as suitably rated

safety valves. The condensate drain must be connected to a

suitable collection and drain system.

9

The choice of system components and the method of their

installation are left up to the heating engineer installing the

system. Installers must use their expertise to ensure proper

installation and functioning in conformity to all applicable

legislation.

9

If needed, water supplies and recovery circuits must be condi-

tioned by suitable treatment systems. Refer to the values list-

ed in the table in the paragraph Water quality requirements.

0

It is prohibited to operate the circulators without water.

Single Boiler Piping Schematic

1

3

15

6

3

3

3

11

3

3

3

3

MAKE-UP

WATER

16

16 1617

FLOW

7*

15

10

1

10

12

3

3

3

9

WATER INLET

7

5

3

5

4

3

3

4

3

8

2

18

M

CENTRAL

HEATING

RETURN

LT

RETURN

HEATING

SUPPLY

1 Boiler

2 Burner

3 Isolation valves

4 Central heating system pump

5 Non-return valves

6 Automatic vent valve

7 Boiler safety valve

7* Second boiler safety valve (only for RTC 8000 - RTC

10000)

8 Boiler drain valve

9 Y lter

10 Pressure reducer

11 Expansion tank

12 Water softener lter

13 Siphon

14 Condensate outlet

15 Drain

16 Isolation valve

17 Non-return valve

18 Air separator

M Pressure gauge

(*)_HT High Temperature

LT Low Temperature

_ _ _ RTC 8000 - RTC 10000

Loading...

Loading...