6

GENERAL

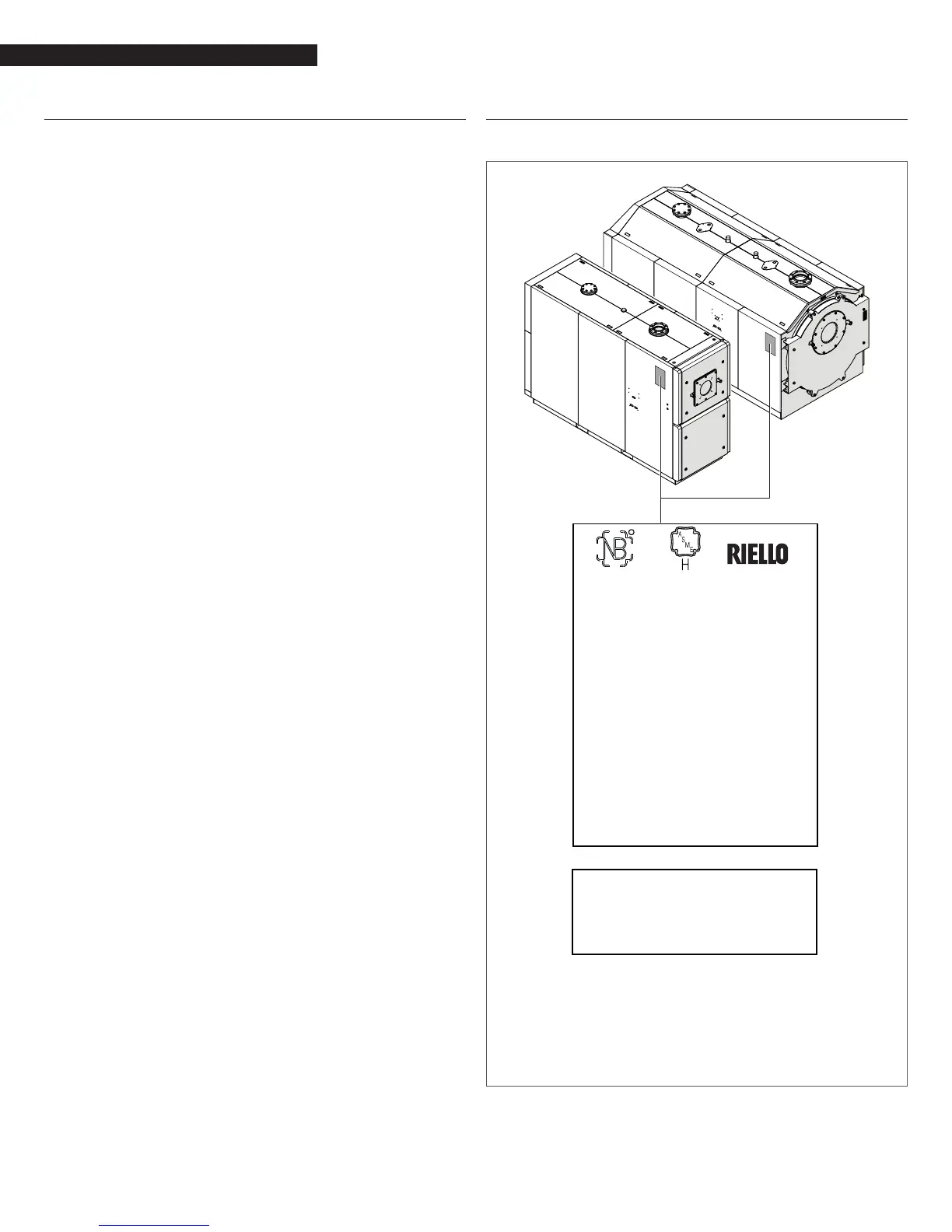

1.3 Description of the appliance

RTC stainless steel boilers are triple ue pass, condensing boil-

ers for installation in a boiler room. They are designed for cen-

tral heating purposes but can also produce domestic hot water in

conjunction with a suitable storage cylinder.

All parts that come into contact with the combustion gases are

made from titanium stabilised stainless steel to ensure maximum

resistance to the corrosive action of acid condensation.

The boiler has been designed with the combustion chamber at

the top and the smooth pipe tube bundle at the bottom to op-

timise heat exchange and energy efciency and to maximise the

condensing effect.

The boiler has a high total water content which is differentially

distributed between its top and bottom sections. This allows out-

going water to reach the set temperature quickly while maintain-

ing the condensing effect and the water heating time around the

tube bundle for as long as possible.

RTC boilers feature low pressure combustion chambers for a

smoother burner action, and temperature-resistant, stainless

steel turbulators inside the tube bundle for maximum burner ef-

ciency.

The boiler body is thoroughly insulated with a layer of high density

glass wool.

The boiler casing is made from painted steel sheet.

The boiler's front door and ue gas chamber can be opened com-

pletely to facilitate inspection, maintenance and cleaning of in-

ternal parts and to speed up servicing in general.

The front door can open in either direction and can be opened

without removing the burner. The door comes tted with hinges

on the right, but these can be reversed if necessary to suit indi-

vidual installations.

1.4 Identication

The products are identied by:

2

Gross output

Net IBR rating

Certified by

RIEL

_____________________

LO S.p.A. (ITALY)

EV OBA

FRONT

_____________________

MINIMUM CLEARANCES TO COMBUSTIBLE CONSTRUCTION

FOR INSTALLATION ON NON COMBUSTIBLE FLOORS ONLY

ALL OF THE INSTRUCTIONS MUST BE FOLLOWED EXACTLY

_____________________

_____________________

_____________________

_____________________

SIDES

A ND RE AR

DRAFT HOOD

VENT CONNECTO R

BAROMETRIC DAMPER

4

” ( )

r

kW

Mbtu/hr

Mbtu/h

CHIMNEY CONNECTOR

Mo

____

del

bar kPa psi

° F° C

m

kg/h lb/hr

Mbtu/hr

kW

gph=xaM hpg

kW /

kW

MAWP Water

Maximum water temp.

Heating surface

Minimum relief valve capacity

Electrical rating (burner)

SERIAL NUMBER

mm

)

mm

18” (457

mm

)

Less than 12 Amperes

Min. & Max. input gas:

18” (457

mm

)

R

2

6

”

(

1

5

2

610

::rof erusserP telnI

Design Manifold Pressure for: NG ___ "

wc to

___ "wc or LP ___"wc to ___ "wc

SQ FT

NG ___ "

wc to

___ "wc or LP ___"wc to ___ "wc

Min =

Min. & Max. input oil: Min =

Max =

/

Mbtu/h

r

Year built:

________

_________

Approved for use with Natural Gas (NG), Liquid Petroleum Gas (LPG), and/or

fuel oil not heavier than # 2 per ASTM D396.

Consult the Installation Manual for approved boiler and burner combinations.

,

Data plate

This lists the technical specications and performance of the

product. This is supplied inside the document bag and MUST BE

APPLIED to the boiler by the installer on completion of instal-

lation. If you damage or lose this label, order a replacement

immediately from Technical Assistance Service.

9

If these plates or any other means of clearly identifying the

product are defaced, removed or lost, proper installation and

servicing may be rendered difcult.

Loading...

Loading...