[ 41 ]

5.2 Cylinder

The ROTEX GasSolarUnit/GasCompactUnit is a

DHW cylinder developed in accordance with

the latest know-how regarding water hygiene

with an integral gas fired condensing boiler

(Fig. 2.1.1 and 2.1.2).

The cylinder is a twin-wall plastic

construction. The space between the internal

and external wall is filled with thermal foam

insulation. This design results in excellent

thermal insulation and very low surface heat

losses.

The 3-4 mm thick outer skin is impact and

shock-proof and protects the cylinder against

damage. During commissioning,t he cylinder is

filled once with water. This water is

unpressurised and will not be replaced during

use.

The cylinder water can be heated by a number

of different means:

1) by the integral gas fired condensing boiler

2) with the GSU via an additionally connected

solar heating system (ROTEX Solaris

system)

3) or via additional heat sources that are

directly connected to the unpressurised

area (e.g. a DHW heat pump)

The DHW is heated inside the spiral heat

exchanger constructed from corrugated

stainless steel pipe, that is located inside the

cylinder and is fully surrounded by the cylinder

water. The specific hygienic water properties

of the GasSolarUnit/GasCompactUnit are

based on the separation of the unpressurised

cylinder water and the DHW flowing through

the corrugated pipe heat exchanger.

The DHW zone (pos. D) is a combination of

DHW cylinder and instantaneous water heater.

The replenishing cold water is initially routed

inside the heat exchanger (pos. 18) to the

bottom of the cylinder to cool down the solar

zone (pos. E) as far as possible. On its path

upwards, the DHW continuously absorbs the

heat of the unpressurised cylinder water

(pos C), resulting in a distinct temperature

stratification inside the cylinder.

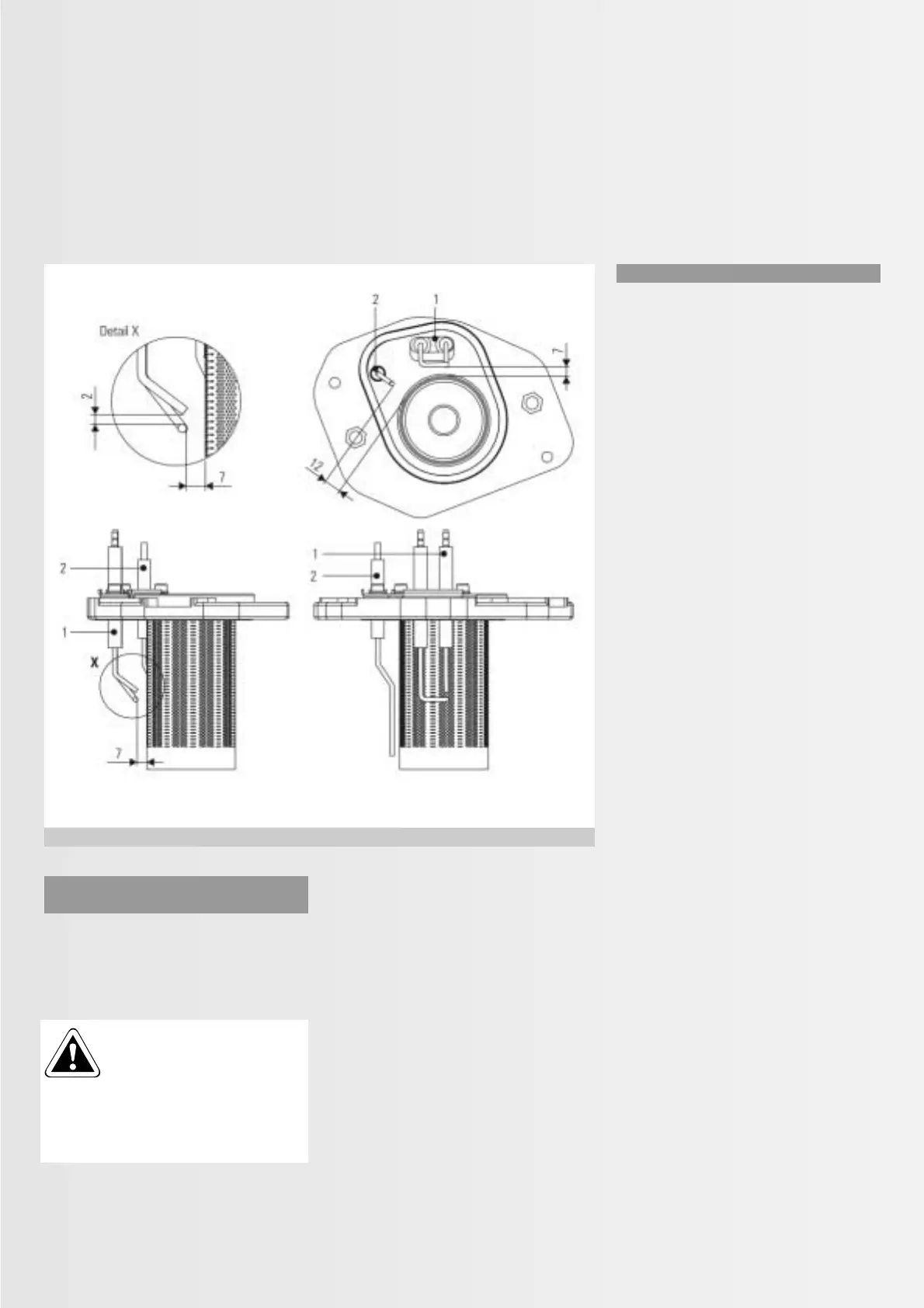

Fig. 05.01.10: Adjusting the ignition and ionisation electrodes

Adjusting the ignition and

ionisation electrodes

The electrodes are adjusted at the factory for

optimum performance. Adjust or replace them

in accordance with Fig. 5.1.10, should they

have been bent out of shape.

Please note: The electrodes

are brittle and can easily break

off if they are bent in a cold

state. For a re-adjustment of the

electrodes, remove the burner and heat

up the electrodes to incandescence with

a blow torch prior to bending.

Loading...

Loading...