www.scheppach.com

GB

|

35

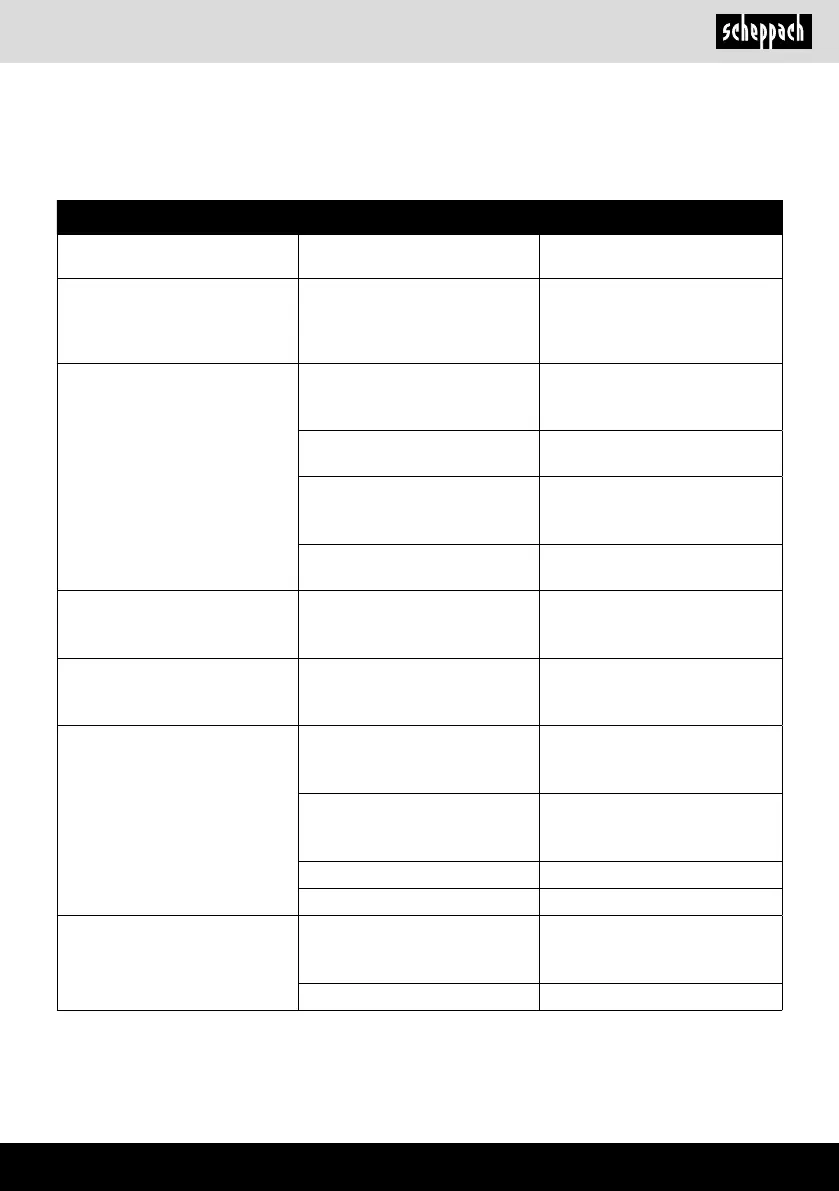

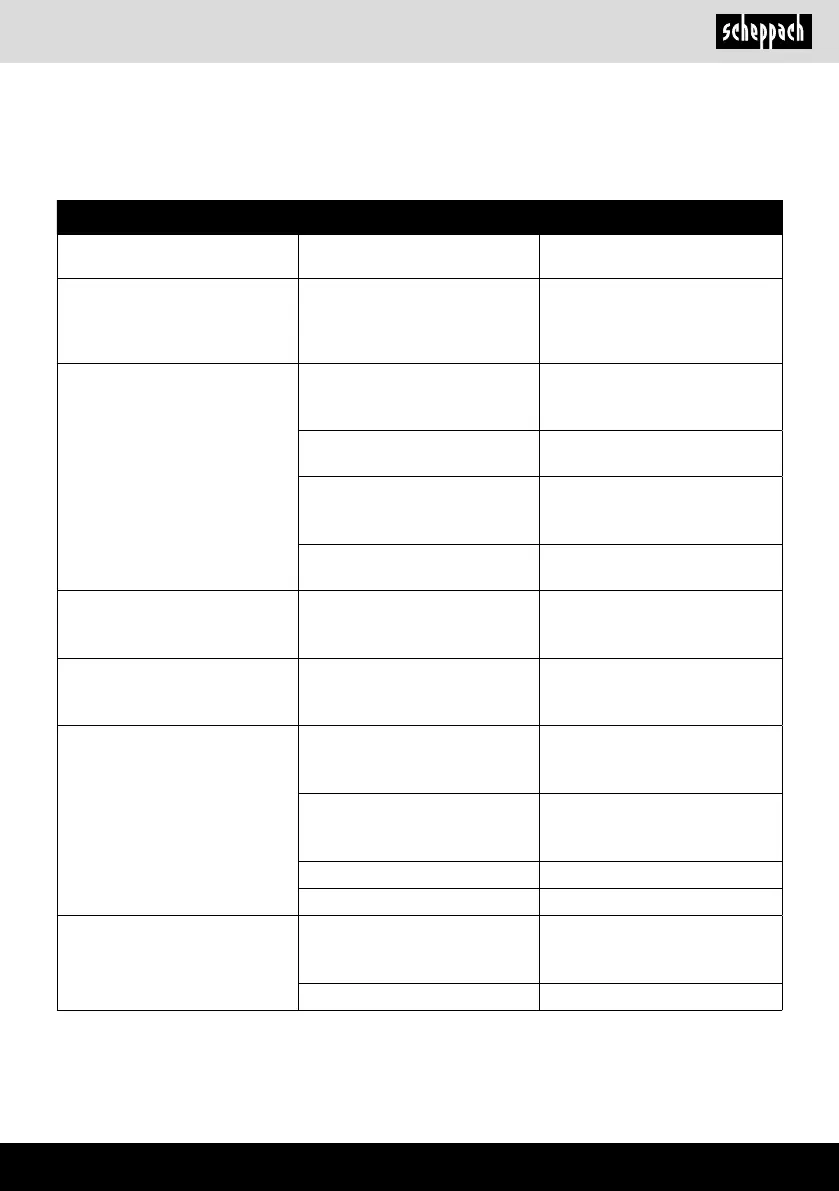

14. Troubleshooting

Warning:

Switch the machine OFF and remove the mains plug from the power outlet.

Fault Problem Solution

The axis returns to its starting

position too quickly or too slowly

Spring tension is set incorrectly. Setting the spring tension, see also

“Spindle return spring”.

The chuck keeps loosening from the

spindle despite being reattached.

Dirt, grease or oil on the spindle or

on the inside of the chuck.

Use a household detergent to clean

the surface of the spindle and drill

chuck. See also “Installing the drill

chuck”

Strong noise development during

operation

Wrong V-belt tension. Set the V-belt tension. See also

“Setting the speed and V-belt

tension”.

The spindle is too dry. Test the spindle. See also

“Lubrication”.

Pulley on the spindle is loose. Check the nut on the pulley for firm

seating and tighten it if necessary.

Pulley on the motor is loose. Tighten the set screw on the motor

pulley.

Wood splinters at the opening of

the drill

No suitable base under the

workpiece.

Use a suitable and stable base. See

also “Adjusting the table and the

workpiece”.

The workpiece snaps out of your

hand.

No suitable base under the

workpiece or not firmly fixed.

Reline the workpiece or fasten it.

The drill anneals. Wrong speed. Change the speed. See also

“Setting the speed and V-belt

tension”.

No chips come out of the borehole. Regularly drive the drill out of the

drill hole to remove the chips.

Blunt drill. Sharpen the drill.

Feed too low. Increase the feed.

The drill is running or the hole is out

of centre

Hard areas in the wood or the

length and angle of the drill bit is

different.

Sharpen the drill.

Drill is bent. Exchange the drill.

Loading...

Loading...