english 3

Dear customer,

we wish you a pleasant and successful working experience

with your new scheppach machine.

According to the applicable product liability law the manu-

facturer of this device is not liable for damages which arise

on or in connection with this device in case of:

• improperhandling,

• non-compliancewiththeinstructionsforuse,

• repairsbythirdparty,nonauthorizedskilledworkers,

• installationandreplacementofnon-originalspareparts,

• improperuse,

• failures of the electrical system due to the non-com-

pliance with the electrical specifications and the

VDE0100,DIN57113/VDE0113regulations

Recommendations:

Read the entire text of the operating instructions prior to

the assembly and operation of the device.

These operating instructions are intended to make it easier

foryoutogetfamiliarwithyourdeviceandutilizeitsin-

tended possibilities of use.

The operating instructions contain important notes on how

to work safely, properly and economically with your ma-

chineandhowtoavoiddangers,saverepaircosts,reduce

downtime,andincreasethereliabilityandworkinglifeof

the machine.

Inadditiontothesafetyregulationscontainedherein,you

must in any case comply with the applicable regulations of

your country with respect to the operation of the machine.

Put the operating instructions in a clear plastic folder to

protectthemfromdirtandhumidity,andstorethemnear

the machine. The instructions must be read and carefully

observed by each operator prior to starting the work. Only

persons who have been trained in the use of the machine

and have been informed on the related dangers and risks

are allowed to use the machine. The required minimum

age must be met.

In addition to the safety notes contained in the present

operating instructions and the special regulations of your

country, the generally recognized technical rules for the

operation of wood working machines must be observed.

Controls and features, Fig. 2

1 = Oil Tank 10 = Pushbutton Box

2 = Log Pusher 11 = Transport Wheel

3 = Work Table 12 = Lift Handle

4 = Wedge 13 = Hydraulic Lever

5 = Lift Handle

6 = Support Leg 15 = Bleed Screw

7=WorkTableExtension 16=OilDrainBoltw/

8 = Switch Dipstick

9=Motor 17=Back-RunStop

General Notes

• Whenyouunpackthedevice,checkallpartsforpossible

transportdamages.Incaseofcomplaintsthesupplieris

to be informed immediately. Complaints received at a

later date will not be acknow ledged.

• Checkthedeliveryforcompleteness.

• Readtheoperatinginstructionstomakeyourselffamil-

iar with the device prior to using it.

• Onlyuseoriginalscheppachpartsforaccessoriesaswell

as for wearing and spare parts. Spare parts are available

fromyourspecializeddealer.

• Specifyourpartnumbersaswellasthetypeandyearof

construction of the device in your orders.

In these operating instructions we have marked the places

that have to do with your safety with this sign: m

m General Safety Rules

• Observeallsafetyinstructionsandwarningsattachedto

the machine.

• Seetoitthatsafetyinstructionsandwarningsattached

to the machine are always complete and perfectly leg-

ible.

• Thesafetymechanismonthe machinemaynot bere-

moved or disengaged.

• Checkallpowersupplies.Donotusedefectivelines.

• Beforeinitialoperationchecktobesurethetwo-handed

operation is properly functioning.

• Operatingpersonnel mustbeat least18 yearsof age.

Traineesmustbeatleast16yearsofage,butmayonly

operate the machine under adult supervision.

• Alwayswearearprotectionandworkgloveswhenwork-

ing.

• Cautionwhenworking:Thereisadangertongersand

hands from the splitting tool.

• For heavy or cumbersome pieces, use the appropriate

working aids for bracing.

• Cleaning,changingandsettingofthemachinemayonly

be carried out when the motor is switched off. Pull the

power supply plug.

• Connection,maintennaceandrepairworkontheelectri-

cal installation my be carried out only by qualified per-

sonnel.

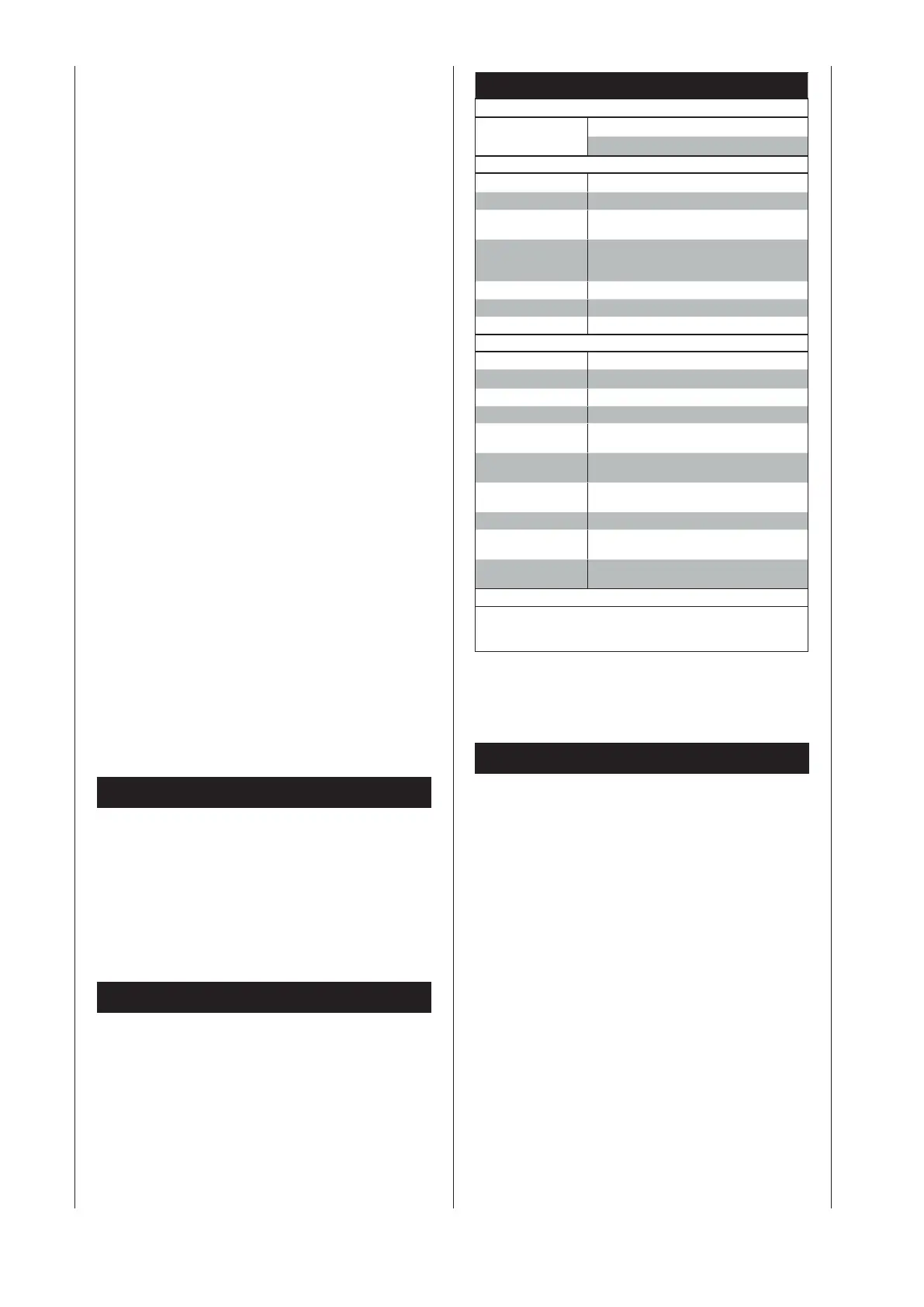

Ox t 500

Scope of Delivery

Hydraulic Log Splitter

Operation Manual

Technical Data

Dimensions LxWxH

48¾“x243/8“x383/8“

Wood ø min - max

2“ – 10“

Wood Length min

- max

77/8”–201/2”

Distance - Log

pusher– Splitting

knife

77/8”/57/8”/315/16”

Return stroke stop

3 positions

No Volt release

yes

Weight

110 lbs

Motor

Motor V/Hz

110 / 60

Current Amps

15

Splitting Power t*

4

Cylinder rise

129/16”

Cylinder speed (fast

fwd.)

13/16“/sec

Cylinder speed

(return)

31/8”/sec

Hydraulic fluid

capacity

5/8gal

Motor speed rpm

2800

Adjusting log pusher

(2 holes)

2x2”

Hydraulic pressure

MPa

18

Subject to technical changes!

* The maximum achievable splitting power depends on the resist-

anceofthematerialtobesplitandcan,duetoinuencingvari-

able,deecttothehydraulicsystem.

Loading...

Loading...