english 5

Setup

Prepare the workplace where the machine is to be placed.

Ensure sufficient room to allow safe work without malfunc-

tions.

The machine is designed to operate on a level surface and

mustbeplacedsecurelyonrm,levelground.

Please make sure your scheppach machine is placed firmly

on stable plain ground.

Assembly

Forpackagingreasons, thebase(6)istobeinstalledby

the customer.

Usethe5saucer-headscrewsM8x12thatareincludedin

the delivery.

Placethedevicehorizontallyontheoor,andputtheSty-

ropor pad of the packaging underneath the splitting wedge

side.

m Electrical connection

The installed electric motor is completely wired ready for op-

eration.

The customer’s connection to the power supply system, and

any extension cables that may be used, must conform with

local regulations.

Important remark:

The motor is automatically switched off in the event of an

overload. The motor can be switched on again after a cool-

ing down period that can vary.

Defective electrical connection cables

Electrical connection cables often suffer insulation dam-

age.

Possible causes are:

• Pinch points when connection cables are run through

window or door gaps.

• Kinksresultingfromincorrectattachmentorlayingof

the connection cable.

• Cuts resulting from running over the connecting cable.

• Insulationdamageresultingfromforcefullypullingout

of the wall socket.

• Cracks through aging of insulation.

Such defective electrical connection cables must not be

used as the insulation damage makes them extremely haz-

ardous.

Check electrical connection cables regularly for damage.

Make sure the cable is disconnected from the mains when

checking.

Electrical connection cables must comply with the regula-

tionsapplicableinyourstate/localjurisdiction.

Single-phase motor

• The mains voltage must coincide with the voltage speci-

edonthemotor’sratingplate.

• Doubleinsulatedtools areequippedwith apolarized

plug(onebladeiswiderthantheother.)Thisplugwill

tinapolarizedoutletonlyoneway.Iftheplugdoes

not t fully in the outlet, reverse the plug. If it still

does nott,contact a qualied electrician to install

apolarizedoutlet.Donotchangethepluginanyway.

Warning: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Double insulation eliminates the need for the three

wire grounded power cord and grounded power sup-

plysystem.Beforeplugginginthetool,becertainthe

outlet voltage supplied is within the voltage marked on

the nameplate.

• The connection to the mains must be protected with a

16 A slow-acting fuse.

Extension cords

• The use of any extension cord will cause some drop in

voltage and loss of power.

• Wiresoftheextensioncordmustbeofsufcientsize

to carry the current and maintain adequate voltage.

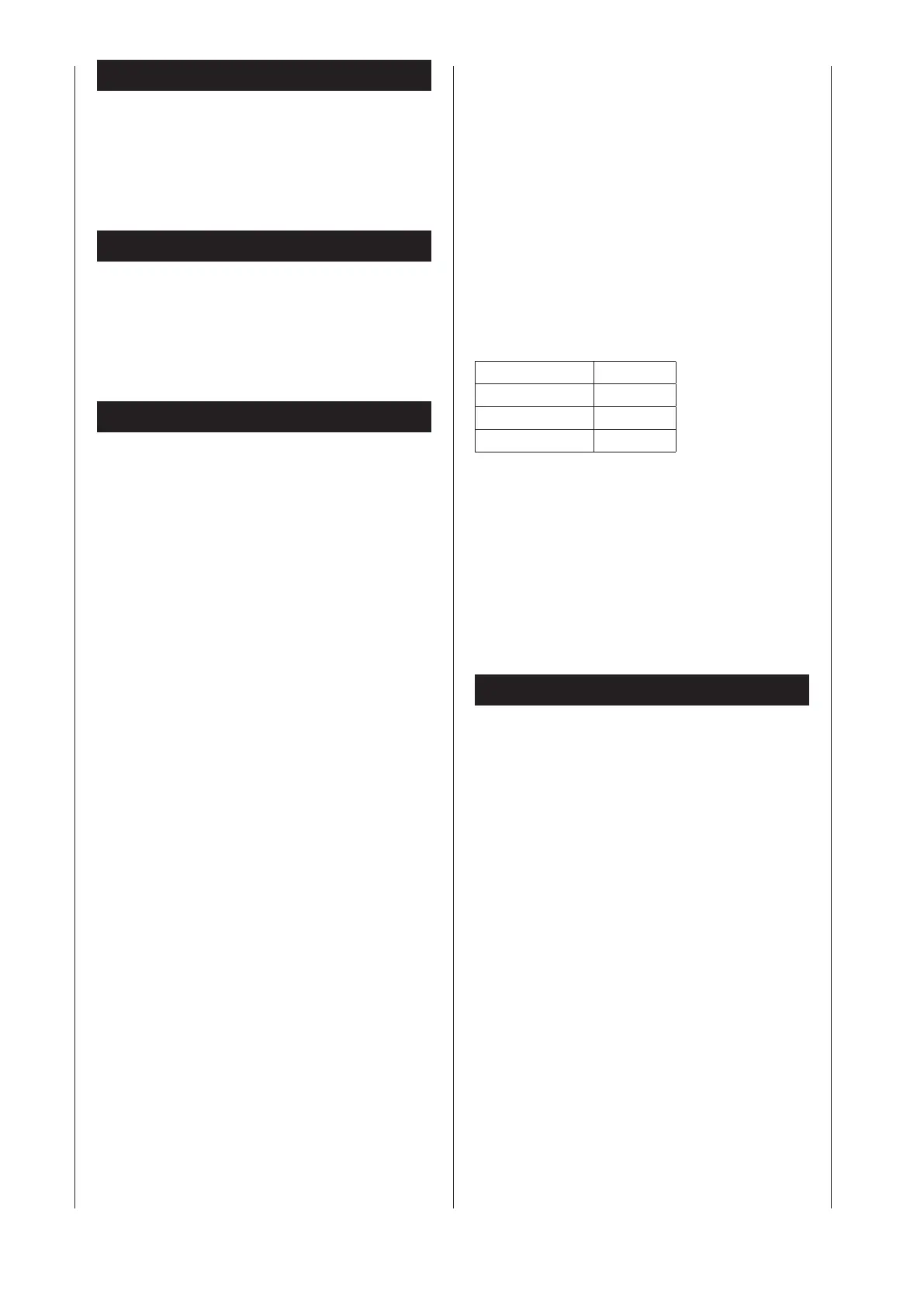

• Use the table to determine the minimum wire size

(A.W.G.)extensioncord.

• Iftheextensioncordisworn,cut,ordamagedinany

way,replaceitimmediately.

EXTENSIONCORDLENGTH

Wire Size A.W.G.

Upto58ft. 18

25 to 100 ft. 16

100 to 150 ft. 14

Note: Usingextensioncordsover150ft.longisnotrec-

ommended.

Only a qualified electrician is permitted to connect the

machine and complete repairs on its electrical equip ment.

Intheeventofenquiriespleasespecifythefollowingdata:

• Motor manufacturer

• Type of current of the motor

• Datarecordedonthemachine’sratingplate

• Datarecordedontheswitch’sratingplate

.

Operation

Before operating your scheppachmachine,the bleed screw

should be loosened by some rotations until air can go in

and out of the oil tank smoothly. Failed to loosen the bleed

screw will keep the sealed air in hydraulic system being

compressed after being decompressed. Such continuous

compression/decompressionwillblowoutthesealsofthe

hydraulic system and cause permanent damage to your

scheppach machine.

Before moving your scheppach machine, make sure the

bleed screw is tightened to avoid oil leaking from this

point.

Only split plain cut log.

1.Placethelogplainontotheworktable(3).

2. Fix the log pusher in the required position according to

the length of the log.

Position 1: Length up to 201/2”,

Position 2: Length up to 181/2”,

Position 3: Length up to 161/2”.

3.Complyingwithregulationsandforyoursafety,thehy-

draulic log splitter features two-handed control.

Tostartthesplittingprocess,youmustsimultaneously

press the lever (13) with your left hand and the start

button(8)intheswitchboxwithyourrighthand.

Releasing one of the two control elements will immedi-

ately stop the splitting process, releasing both control

elements will abort the splitting process.

Thepressureplate(2)willthenmovebackintoitshome

position.

Loading...

Loading...